Drying processes are essential in numerous industries, from food processing to pharmaceuticals and chemical manufacturing. Two prominent drying techniques include vacuum drying and heat drying. Each method has its unique advantages, applications, and limitations. In this article, we will explore the differences between vacuum drying and heat drying, their mechanisms, benefits, and potential drawbacks.

Vacuum Drying

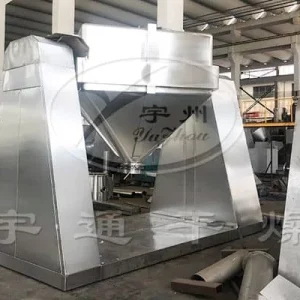

Vacuum drying is a process that removes moisture from materials by reducing the atmospheric pressure around them. This reduction in pressure lowers the boiling point of water, allowing it to evaporate at lower temperatures than under normal atmospheric conditions. Vacuum drying is particularly useful for heat-sensitive materials, as it prevents degradation and maintains product quality.

Mechanism of Vacuum Drying

The vacuum drying process involves placing the material in a sealed chamber and creating a vacuum using a vacuum pump. As the pressure decreases, the boiling point of water also decreases, causing the moisture in the material to vaporize more easily. The vaporized moisture is then removed from the chamber through the vacuum pump, leaving the dried material behind.

Benefits of Vacuum Drying

1. Lower drying temperature: Vacuum drying allows for the removal of moisture at lower temperatures, which is ideal for heat-sensitive materials like certain foods, pharmaceuticals, and biological products.

2. Reduced oxidation: The low-oxygen environment created by the vacuum helps prevent oxidation, preserving the color, flavor, and nutritional value of the material.

3. Uniform drying: Vacuum drying ensures even distribution of heat and pressure, resulting in uniform drying throughout the material.

4. Faster drying time: Vacuum drying can be faster than conventional heat drying due to the reduced boiling point of water.

Drawbacks of Vacuum Drying

1. Higher initial investment: Vacuum drying equipment can be more expensive than heat drying systems, leading to higher initial costs.

2. Longer drying cycles: Although vacuum drying can be faster in some cases, it may require longer drying times for certain materials, especially those with high moisture content.

3. Limited capacity: Vacuum dryers typically have smaller capacities compared to heat dryers, making them less suitable for large-scale operations.

Heat Drying

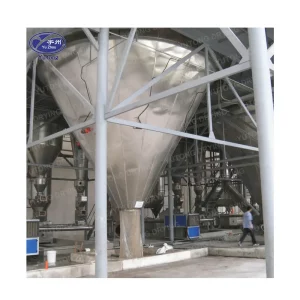

Heat drying, also known as convection drying, is a common drying method that uses hot air or other heated gases to remove moisture from materials. The heated gas is circulated around the material, causing the moisture to evaporate and be carried away by the airflow.

Mechanism of Heat Drying

In heat drying, the material is placed in an open chamber or conveyor system where hot air or gas is blown over it. The heat energy is transferred to the material, causing the moisture to evaporate. The humid air is then exhausted from the system, while the dried material remains.

Benefits of Heat Drying

1. High capacity: Heat dryers can handle large volumes of material, making them suitable for industrial-scale operations.

2. Lower operating costs: Heat drying systems are generally less expensive to operate than vacuum dryers, as they require less energy and maintenance.

3. Versatility: Heat drying can be used for a wide range of materials, including grains, seeds, wood, and plastics.

4. Shorter drying times: Heat drying can often achieve faster drying times than vacuum drying, especially for materials with lower moisture content.

Drawbacks of Heat Drying

1. Higher drying temperature: Heat drying requires higher temperatures, which can cause degradation of heat-sensitive materials, leading to loss of quality.

2. Uneven drying: Heat drying may result in uneven drying, especially in materials with irregular shapes or sizes.

3. Increased oxidation: The exposure to oxygen during heat drying can lead to oxidation, affecting the color, flavor, and nutritional value of the material.

Vacuum drying and heat drying both have their unique advantages and disadvantages. Vacuum drying is ideal for heat-sensitive materials and offers benefits such as lower drying temperatures, reduced oxidation, and uniform drying. However, it may require higher initial investments and longer drying cycles. Heat drying, on the other hand, is suitable for industrial-scale operations, offers lower operating costs, and can handle a wide range of materials. Nonetheless, it may cause degradation of heat-sensitive materials and result in uneven drying.

Choosing the appropriate drying method depends on the specific requirements of the application, including the nature of the material, desired drying time, and budget constraints. In some cases, a combination of both methods may be used to optimize the drying process for maximum efficiency and product quality.