A fluidized bed dryer is a specialized piece of equipment widely used in various industries for drying a diverse range of materials. This drying method offers several unique advantages and finds applications in multiple sectors where efficient and high-quality drying is essential.

What is a Fluidized Bed Dryer?

At its core, a fluidized bed dryer consists of a chamber or container through which a gas, usually air, is passed upward at a controlled velocity. The material to be dried is placed on a perforated plate or a bed within the chamber. As the gas passes through the perforations, it lifts and suspends the particles of the material, creating a fluid-like state similar to a boiling liquid. This phenomenon is known as fluidization.

The fluidization process has several important characteristics. First, it provides excellent heat and mass transfer between the gas and the material being dried. The suspended particles have a large surface area exposed to the drying medium, which accelerates the evaporation of moisture. The continuous movement and mixing of the particles also ensure uniform drying throughout the batch, minimizing the risk of uneven drying or hot spots.

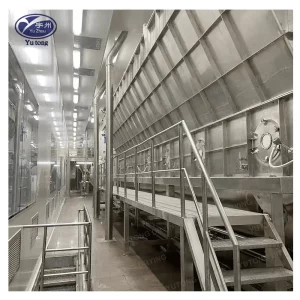

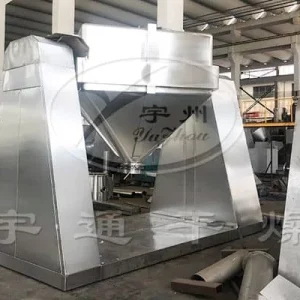

The construction of a fluidized bed dryer typically includes a gas distribution system, a drying chamber, a product inlet and outlet, and a heating system. The gas distribution system is designed to ensure a uniform flow of gas across the bed, maintaining stable fluidization. The drying chamber is usually made of stainless steel or other suitable materials to withstand the operating conditions and prevent corrosion. The product inlet and outlet are designed for easy loading and unloading of the material, and may be equipped with valves or gates to control the flow. The heating system can be in the form of steam coils, hot air generators, or electric heaters, depending on the specific requirements of the drying process.

There are different types of fluidized bed dryers, including batch and continuous models. Batch fluidized bed dryers are suitable for small to medium-sized batches and offer flexibility in operation. They can be loaded with the material, dried, and then unloaded, allowing for easy cleaning and maintenance between batches. Continuous fluidized bed dryers, on the other hand, are designed for large-scale production and provide a continuous flow of material through the dryer. These dryers are often used in industries where high throughput is required.

Where is it Used?

The fluidized bed dryer finds extensive use in various industries due to its versatility and efficiency. Some of the key industries where it is commonly employed include:

Pharmaceuticals

In the pharmaceutical industry, fluidized bed dryers are used for drying a wide range of products such as granules, powders, and tablets. The gentle drying process and uniform heat transfer are ideal for heat-sensitive pharmaceutical ingredients, ensuring that the active substances are not degraded. Fluidized bed drying also helps in controlling the particle size and morphology of the dried product, which is important for proper formulation and dissolution of drugs. For example, in the production of granules for oral solid dosage forms, fluidized bed drying can improve the flowability and compressibility of the granules, enhancing the manufacturing process.

Food Industry

The food industry uses fluidized bed dryers for drying various food products such as fruits, vegetables, grains, and spices. The rapid drying and uniform heat distribution help in preserving the nutritional value, flavor, and color of the food. Fluidized bed drying can also be used to remove excess moisture from food products, increasing their shelf life and reducing the risk of spoilage. For instance, in the production of instant coffee or powdered milk, fluidized bed drying is an essential step to obtain a dry and stable product.

Chemical Industry

In the chemical industry, fluidized bed dryers are used for drying chemicals, pigments, catalysts, and other fine powders. The ability to handle a wide range of particle sizes and the efficient drying process make it suitable for various chemical applications. Fluidized bed drying can also be used to remove solvents or moisture from chemical products, ensuring product quality and safety. For example, in the production of polymer resins, fluidized bed drying can help in removing residual monomers and solvents, improving the purity and properties of the resin.

Agriculture Industry

The agriculture industry uses fluidized bed dryers for drying agricultural products such as seeds, grains, and nuts. The gentle drying process and uniform heat transfer help in preserving the viability and quality of the seeds. Fluidized bed drying can also be used to remove moisture from grains and nuts, preventing mold growth and improving storage stability. For example, in the drying of corn or soybeans, fluidized bed drying can reduce the moisture content to a safe level for storage and transportation.

Minerals and Metals Industry

In the minerals and metals industry, fluidized bed dryers are used for drying minerals, ores, and metal powders. The high drying capacity and efficient heat transfer make it suitable for large-scale processing. Fluidized bed drying can also be used to remove moisture from metal powders, improving their flowability and reducing the risk of oxidation. For example, in the production of iron ore pellets, fluidized bed drying is an important step to increase the strength and stability of the pellets.

In conclusion, a fluidized bed dryer is a valuable piece of equipment that offers efficient and uniform drying for a wide range of materials. Its versatility and effectiveness make it an essential tool in various industries, from pharmaceuticals and food to chemicals and minerals. As technology continues to advance, fluidized bed dryers are likely to become even more efficient and adaptable, meeting the evolving needs of different industries.