Vacuum dryers are widely used in various industries for drying different materials. They offer several advantages but also come with some limitations. In this article, we will explore the advantages and disadvantages of vacuum dryers.

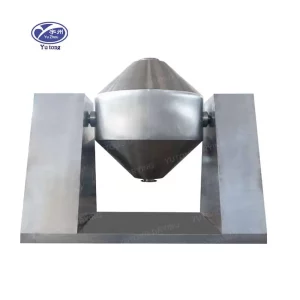

Drying is an essential process in many industries, as it helps to remove moisture from materials, increase their shelf life, and improve their quality. Vacuum dryers use a combination of reduced pressure and heat to achieve efficient drying. They are particularly useful for drying heat-sensitive materials that may be damaged by high temperatures or oxidation.

Advantages of Vacuum Dryers

1. Gentle Drying Process

One of the main advantages of vacuum dryers is their gentle drying process. By operating at reduced pressure, the boiling point of water and other solvents is lowered. This allows for drying at lower temperatures, which is beneficial for heat-sensitive materials.

Materials such as pharmaceuticals, food products, and biological samples can be dried without being exposed to high temperatures that could degrade their quality or cause chemical reactions.

2. Enhanced Drying Efficiency

Vacuum dryers offer enhanced drying efficiency compared to traditional drying methods. The reduced pressure inside the dryer accelerates the evaporation of moisture, allowing for faster drying times.

This is especially useful for materials with high moisture content or those that require thorough drying. The efficient drying process can also lead to energy savings, as less heat is required to achieve the desired drying results.

3. Improved Product Quality

Vacuum drying can result in improved product quality. The low-temperature drying process helps to preserve the integrity of the material being dried, reducing the risk of degradation or damage.

For example, in the pharmaceutical industry, vacuum drying can help maintain the potency and stability of drugs. In the food industry, it can preserve the flavor, color, and nutritional value of food products.

4. Reduced Oxidation and Degradation

Vacuum dryers create an oxygen-deprived environment, which reduces the risk of oxidation and degradation of the dried material. This is particularly important for materials that are sensitive to air and moisture.

By minimizing oxidation, vacuum drying can extend the shelf life of the product and improve its storage stability.

5. Versatility

Vacuum dryers are highly versatile and can be used to dry a wide range of materials. They can handle both solid and liquid materials, as well as materials with different particle sizes and shapes.

The drying parameters can be adjusted to meet the specific requirements of each material, making vacuum dryers suitable for a variety of applications in different industries.

Disadvantages of Vacuum Dryers

1. High Initial Cost

One of the major disadvantages of vacuum dryers is their high initial cost. The equipment required for vacuum drying is complex and expensive, including the dryer itself, vacuum pumps, and control systems.

This can be a significant investment for small businesses or startups, making it less accessible compared to other drying methods.

2. Maintenance and Operation Costs

Vacuum dryers also have relatively high maintenance and operation costs. The vacuum pumps require regular maintenance and may need to be replaced over time. Additionally, the energy consumption of vacuum dryers can be significant, especially if they are operated continuously.

These costs can add up and impact the overall profitability of using vacuum dryers, especially for applications with large volumes of material to be dried.

3. Limited Capacity

Vacuum dryers often have limited capacity compared to some other drying methods. The size and design of the dryer may restrict the amount of material that can be dried at one time.

For large-scale production or applications with high throughput requirements, multiple vacuum dryers may be needed, which further increases the cost and complexity of the drying process.

4. Complex Operation

Operating a vacuum dryer requires a certain level of technical expertise. The process involves controlling the pressure, temperature, and drying time accurately to achieve optimal drying results.

This complexity can make it more challenging for operators who are not familiar with vacuum drying technology. Training and experience are often required to ensure proper operation and maintenance of the equipment.

5. Potential for Vacuum Leaks

Vacuum dryers rely on a tight vacuum seal to maintain the reduced pressure inside the dryer. However, there is always a risk of vacuum leaks, which can disrupt the drying process and affect the quality of the dried product.

Detecting and repairing vacuum leaks can be time-consuming and may require specialized equipment and expertise.

Vacuum dryers offer several advantages, including a gentle drying process, enhanced drying efficiency, improved product quality, reduced oxidation and degradation, and versatility. However, they also have some disadvantages, such as high initial cost, maintenance and operation costs, limited capacity, complex operation, and the potential for vacuum leaks. When considering using a vacuum dryer, it is important to weigh these advantages and disadvantages against the specific requirements of the drying application. In some cases, the benefits of vacuum drying may outweigh the costs, while in others, alternative drying methods may be more suitable. Ultimately, the choice of drying method depends on factors such as the type of material to be dried, production volume, budget, and quality requirements.