Spray drying is an essential process in the pharmaceutical industry, enabling the production of powders with controlled particle size, morphology, and moisture content. These properties are critical for ensuring the efficacy, stability, and ease of handling of various drug formulations. As demand for spray-dried pharmaceuticals grows, understanding the wholesale prices and cost considerations involved in spray drying becomes increasingly important for manufacturers and suppliers. In this comprehensive article, we will explore the factors influencing spray drying costs, wholesale price ranges, and strategies for optimizing the economic aspects of spray drying in the pharmaceutical industry.

Factors Influencing Spray Drying Costs

Several factors contribute to the overall cost of spray drying in the pharmaceutical industry. Understanding these factors can help manufacturers and suppliers make informed decisions about process optimization and cost management. Key factors include:

1. Raw Material Costs: The cost of the raw materials used in the spray drying process, such as active pharmaceutical ingredients (APIs), excipients, and solvents, significantly impacts the overall cost. The availability, purity, and sourcing of these materials can greatly influence their prices.

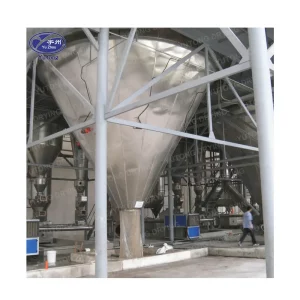

2. Equipment Costs: The initial investment in spray drying equipment, as well as ongoing maintenance and repair expenses, contribute to the overall cost. Factors such as equipment capacity, efficiency, and technological advancements can affect the cost-effectiveness of the spray drying process.

3. Energy Consumption: Spray drying requires significant amounts of energy for atomization, drying, and powder collection. The cost of electricity, steam, or other energy sources can vary depending on regional pricing and efficiency of the drying process.

4. Labor Costs: The cost of skilled labor required to operate and maintain the spray drying equipment, as well as the cost of quality control personnel, influences the overall expense.

5. Process Optimization: The efficiency of the spray drying process, including factors such as drying time, yield, and product quality, can greatly impact the cost. Optimizing the process can lead to reduced waste, increased throughput, and lower overall costs.

6. Regulatory Compliance: Meeting regulatory requirements for quality, safety, and environmental protection can add to the cost of spray drying. Ensuring compliance with Good Manufacturing Practices (GMP) and other industry standards can involve additional expenses for documentation, validation, and audits.

Wholesale Price Ranges for Spray-Dried Pharmaceutical Products

The wholesale price of spray-dried pharmaceutical products can vary widely depending on the specific product, market demand, and production scale. Here are some general price ranges for common spray-dried pharmaceutical products:

1. Active Pharmaceutical Ingredients (APIs): Wholesale prices for spray-dried APIs can range from $10 to $100 per kilogram, depending on the type of API, purity, and production volume.

2. Excipients: Spray-dried excipients, such as lactose, mannitol, and dextran, can be priced between $5 and $50 per kilogram, depending on the specific excipient and production scale.

3. Finished Drug Products: Wholesale prices for spray-dried finished drug products, such as inhalation powders and oral dispersible tablets, can range from $10 to $200 per kilogram, depending on the complexity of the formulation, production scale, and market demand.

Optimizing Spray Drying Costs in the Pharmaceutical Industry

To optimize spray drying costs in the pharmaceutical industry, manufacturers and suppliers can implement several strategies:

1. Raw Material Sourcing: Establishing long-term relationships with reliable suppliers can help secure competitive prices for raw materials. Additionally, exploring alternative sources or negotiating bulk purchasing agreements can lead to cost savings.

2. Equipment Selection: Investing in high-quality, energy-efficient spray drying equipment can reduce operational costs in the long run. Considering factors such as equipment capacity, automation, and maintenance requirements can help identify the most cost-effective solution.

3. Process Optimization: Continuously monitoring and optimizing the spray drying process can lead to improved efficiency and reduced costs. Strategies include optimizing spray nozzle settings, controlling inlet and outlet temperatures, and implementing real-time quality control measures.

4. Energy Management: Implementing energy-saving measures, such as using waste heat recovery systems or optimizing drying temperatures, can significantly reduce energy consumption and costs.

5. Labor Productivity: Training and retaining skilled personnel can improve the efficiency of the spray drying process, leading to reduced labor costs and increased productivity.

6. Regulatory Compliance: Proactively addressing regulatory requirements and investing in quality assurance systems can help avoid costly non-compliance penalties and streamline the production process.

Case Studies

Case Study 1: A pharmaceutical company producing a spray-dried API for a niche market experienced high raw material costs due to limited sourcing options. By establishing a long-term relationship with a reliable supplier and negotiating a bulk purchasing agreement, the company was able to secure a 15% reduction in raw material costs, leading to significant savings in the overall production cost.

Case Study 2: A contract manufacturing organization (CMO) specializing in spray-dried excipients invested in a state-of-the-art spray drying system with advanced automation features. The new equipment led to a 20% increase in production capacity and a 10% reduction in energy consumption, resulting in substantial cost savings and improved competitiveness in the market.

Case Study 3: A pharmaceutical company producing a complex spray-dried drug formulation faced challenges with process efficiency and product quality. By implementing real-time quality control measures and optimizing spray nozzle settings, the company was able to improve the yield by 15% and reduce waste by 20%, resulting in significant cost savings and improved profitability.

Spray drying plays a crucial role in the pharmaceutical industry, enabling the production of powders with controlled properties for various drug formulations. Understanding the factors influencing spray drying costs, as well as the wholesale price ranges for spray-dried pharmaceutical products, can help manufacturers and suppliers make informed decisions about process optimization and cost management. By implementing strategies such as raw material sourcing, equipment selection, process optimization, energy management, labor productivity, and regulatory compliance, companies can achieve cost savings and improve their competitiveness in the market.

FAQs

Q1: What are the main advantages of spray drying in the pharmaceutical industry?

A1: Spray drying offers several advantages in the pharmaceutical industry, including improved particle size and morphology control, enhanced stability and bioavailability of drug substances, reduced moisture content, and easier handling and processing of powders. These benefits contribute to the efficacy, safety, and patient compliance of drug formulations.

Q2: How does spray drying affect the bioavailability of drugs?

A2: Spray drying can enhance the bioavailability of drugs by reducing particle size, increasing surface area, and improving the solubility of poorly water-soluble APIs. Smaller particles and higher surface area facilitate faster dissolution and absorption in the gastrointestinal tract, leading to improved bioavailability.

Q3: Can spray drying be used for all types of drug formulations?

A3: While spray drying is suitable for many drug formulations, such as powders, granules, and pellets, it may not be appropriate for all types of formulations. Factors such as the stability, solubility, and sensitivity of the API, as well as the desired release profile, can influence the suitability of spray drying for a particular formulation.

Q4: What are the environmental impacts of spray drying in the pharmaceutical industry?

A4: Spray drying can have environmental impacts, primarily related to energy consumption, solvent emissions, and waste generation. Implementing energy-saving measures, using environmentally friendly solvents, and optimizing the drying process can help mitigate these impacts.

Q5: How does spray drying compare to other drying methods in terms of cost?

A5: Spray drying can be more expensive than other drying methods, such as tray drying or fluid bed drying, due to higher equipment and energy costs. However, the advantages of spray drying in terms of product quality, process efficiency, and scalability can outweigh the higher costs in many cases.

In conclusion, spray drying is a valuable process in the pharmaceutical industry, offering numerous benefits for drug formulation development and production. By understanding the factors influencing spray drying costs and implementing cost optimization strategies, manufacturers and suppliers can achieve significant savings and improve their competitiveness in the market.