Spray dryer working principle

The working principle of a spray dryer mainly includes the following steps:

Atomization

Centrifugal Atomization: The liquid feedstock is pumped to the top of the spray dryer and enters a high-speed rotating centrifugal atomizer. Under the action of centrifugal force, the liquid is thrown out from the edge of the atomizer in the form of extremely fine filaments or droplets. For example, in some industrial spray dryers, the centrifugal atomizer rotates at a high speed of tens of thousands of revolutions per minute, which can produce droplets with a diameter of several tens of micrometres to several hundred micrometres.

Pressure Atomization: The liquid is pressurized by a high-pressure pump to obtain high-pressure energy and then sprayed out at high speed through a specially designed nozzle. When passing through the nozzle, the pressure energy is converted into kinetic energy, causing the liquid to break up into small droplets due to the shearing force and impact force at the nozzle outlet.

Airflow Atomization: Compressed air or steam is ejected at a high speed (usually ≥300 m/s) from the nozzle. The high-speed gas stream and the liquid come into contact, and the liquid is torn into small droplets by the friction force generated by the large speed difference between the gas and the liquid phases. This method is particularly suitable for viscous materials.

Spray-Air Mixing

After the liquid is atomized into small droplets, it is immediately mixed with the hot air entering the drying chamber. The hot air is usually heated to a certain temperature (usually ranging from 100°C to 300°C or even higher, depending on the material being dried) by a heater before entering the drying chamber. The hot air is evenly distributed in the drying chamber through an air distributor to ensure that the droplets can be fully and uniformly contacted with the hot air, providing sufficient heat transfer conditions for the subsequent evaporation of moisture.

Moisture Evaporation

When the atomized droplets come into contact with the hot air, the heat is quickly transferred from the hot air to the droplets, causing the moisture in the droplets to evaporate rapidly. Due to the large specific surface area of the droplets, the evaporation rate is extremely fast. In general, within a few seconds to tens of seconds, most of the moisture in the droplets can be evaporated, and the solid content in the droplets gradually precipitates and forms solid particles.

Dry Product Separation

The dried solid particles are separated from the exhaust gas in the drying chamber. Commonly, a cyclone separator is used to achieve this separation. The exhaust gas carrying a small amount of fine powder enters the cyclone separator. Under the action of centrifugal force, the solid particles with a larger mass are thrown to the wall of the cyclone separator and fall to the bottom for collection, while the purified exhaust gas is discharged through the exhaust pipe by a fan. In some cases, additional dust collection devices such as bag filters or wet scrubbers may be added to improve the powder collection efficiency further and reduce environmental pollution.

Spray Dryer Advantages

Spray dryers offer several advantages, which make them a popular choice in many industries for drying liquid or slurry materials. Here are the main benefits:

Fast Drying Speed

Spray dryers can convert a liquid feed into a dry powder in a very short time, usually within seconds to minutes. This is because the liquid is atomized into tiny droplets, which have a large surface – to – volume ratio. For example, when drying a milk – based liquid, the small droplets can quickly lose their moisture content upon contact with hot air. The large surface area allows for efficient heat and mass transfer, enabling rapid evaporation of water or other solvents.

Product Quality

Uniform Particle Size: The atomization process in a spray dryer produces droplets of relatively consistent size. As a result, the dried products have a uniform particle size distribution. This is crucial for many applications, such as in the pharmaceutical industry, where consistent particle size is important for drug formulation and bioavailability. For example, when producing a powdered drug, the uniform particle size ensures that the drug dissolves and is absorbed in a predictable manner.

Minimal Heat Damage: The short drying time and the ability to control the drying temperature precisely help to minimize heat – induced degradation of the product. In the food industry, for instance, heat – sensitive substances like vitamins and flavors can be preserved. When drying fruit juices, the rapid drying process helps retain the natural colors, flavors, and nutritional content of the fruits.

3. Versatility

Wide Range of Feed Materials: Spray dryers can handle a diverse range of liquid and slurry materials, including solutions, emulsions, and suspensions. They are used in industries such as food (drying of milk, coffee, and fruit juices), pharmaceuticals (production of powdered drugs and vaccines), and chemicals (drying of pigments, detergents, and catalysts). For example, in the chemical industry, it can be used to dry inorganic salts from their aqueous solutions or to convert liquid polymers into a powder form.

Flexible Product Forms: The dried products can be obtained in different forms, such as free – flowing powders, agglomerates, or microcapsules. By adjusting the drying conditions and sometimes adding specific additives, manufacturers can control the final product form. For example, in the production of instant coffee, the spray – dried coffee powder can be made to have a free – flowing property for easy packaging and use.

High Production Capacity

Spray dryers are available in various sizes and configurations, and large – scale industrial spray dryers can handle a significant amount of feed material per hour. Some large – scale units can process several tons of liquid feed per hour, making them suitable for mass – production operations. This high – capacity production is beneficial for industries that require a large volume of dried products, such as the production of powdered milk in the dairy industry or the manufacturing of bulk chemicals.

Hygienic and Clean Operation

Many spray dryers are designed to meet strict hygiene and cleanliness standards. The drying process is a closed – loop operation in most cases, which reduces the risk of contamination from the external environment. In the pharmaceutical and food industries, this is of utmost importance. The drying chamber and associated components can be easily cleaned and sterilized, ensuring the production of high – quality and safe products.

Spray dryer applications

Spray dryers have a wide range of applications across various industries due to their unique drying capabilities. Here are some of the main areas where spray dryers are used:

1. Food Industry

Dairy Products:

Spray dryers are extensively used to produce powdered milk. Liquid milk is atomized and dried to create a powder that has a long shelf – life and is easy to store and transport. This process also helps in preserving the nutritional content of milk to a large extent.

Whey powder, a by – product of cheese – making, is also produced using spray dryers. It is a valuable ingredient in many food products such as infant formula, sports nutrition products, and bakery items.

Fruit and Vegetable Products:

Fruit juices can be spray – dried to make fruit powder. These powders can be used in the production of instant fruit drinks, flavorings for yogurts and ice creams, and as a natural colorant. For example, spray – dried strawberry powder can add a concentrated strawberry flavor and color to various food products.

Vegetable purees and extracts, like tomato paste or spinach puree, can be converted into powders for use in soups, seasonings, and dehydrated food mixes.

Coffee and Tea:

Instant coffee is a well – known product made using spray dryers. The brewed coffee extract is dried to a powder form, allowing for quick and convenient preparation of coffee.

In the tea industry, spray dryers are used to produce powdered tea or to dry extracts for use in tea – based beverages and supplements.

2. Pharmaceutical Industry

Drug Formulation:

Many active pharmaceutical ingredients (APIs) are dried using spray dryers to convert them into a more stable and easily processable powder form. This is crucial for formulating tablets, capsules, and other dosage forms. For example, antibiotics, anti – inflammatory drugs, and cardiovascular drugs can be spray – dried.

Spray – dried drug particles can have controlled particle sizes and morphologies, which can enhance drug solubility, bioavailability, and stability. Microencapsulation of drugs using spray dryers is also possible, where the drug is encapsulated within a protective shell to control its release rate.

Vaccine Production:

Some vaccines are produced using spray – drying techniques. The process helps in preserving the antigenic properties of the vaccine components while converting them into a more stable powder form. This is beneficial for vaccine storage and transportation, especially in regions with limited cold – chain facilities.

3. Chemical Industry

Pigments and Dyes:

Spray dryers are used to dry pigment slurries and dye solutions. The resulting dry pigments and dyes have a consistent particle size and high color strength. They are used in industries such as paints, inks, plastics, and textiles. For example, titanium dioxide pigment, a widely used white pigment in paints and coatings, can be produced using spray dryers.

Catalysts:

Many catalysts are prepared in powder form using spray dryers. The process allows for precise control of the catalyst particle size and porosity, which are important factors for catalytic activity. These catalysts are used in a variety of chemical reactions such as petroleum refining, petrochemical production, and environmental remediation.

Detergents:

The production of powdered detergents involves the use of spray dryers. The liquid detergent formulation, including surfactants, builders, and other additives, is dried to form a free – flowing powder. This powder can be easily packaged and used in laundry and cleaning applications.

4. Ceramics and Minerals Industry

Ceramic Powders:

Spray dryers are used to produce ceramic powders such as alumina, zirconia, and silica. These powders are used in the manufacturing of ceramic products like tiles, pottery, and advanced ceramics for electronics and aerospace applications. The spray – drying process helps in obtaining a uniform particle size and a well – dispersed powder, which is essential for high – quality ceramic production.

Mineral Processing:

In the mining and mineral processing industry, spray dryers can be used to dry mineral concentrates such as iron ore, copper ore, and zinc ore. The dried ores are more suitable for further processing steps such as smelting and refining.

Understanding the Basics of Spray Drying

Spray drying is a fascinating process widely used in various industries to produce dry powders from liquids. Its efficiency and versatility make it an essential technique in sectors ranging from food production to pharmaceuticals. In this article, we will delve into the spray drying principle, explore its operation process, and examine its applications in different industries.

What is a Spray Dryer?

A spray dryer is a device that transforms a liquid into a dry powder by rapidly drying with a hot gas. This method is preferred when the final product must meet precise standards in particle size and moisture content.

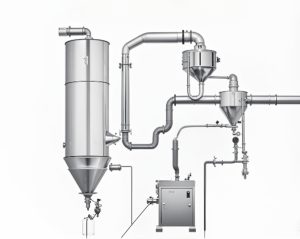

Key Components of a Spray Dryer

The primary components of a spray dryer include the atomizer, drying chamber, and collection system. The atomizer is the heart of the spray dryer, responsible for breaking down the liquid into droplets. It plays a pivotal role in determining the final product’s characteristics. The drying chamber is where the magic happens; it is designed to allow maximum exposure of the droplets to hot air, ensuring efficient drying. The collection system’s role is to gather the dried particles efficiently, ensuring minimal product loss.

Types of Atomizers

There are various types of atomizers used in spray drying, each with its unique advantages. Rotary atomizers are commonly used for their ability to handle a broad range of viscosities and produce uniform droplets. Nozzle atomizers, on the other hand, are preferred for high-pressure applications and are known for their precision. Ultrasonic atomizers are less common but offer exceptional control over droplet size, making them ideal for specific applications requiring fine particles.

Importance of Particle Size

Particle size is a critical factor in spray drying, influencing the final product’s properties, including solubility, flowability, and stability. A well-designed spray drying process ensures consistent particle size, which is vital for applications in industries such as pharmaceuticals, where precise dosage and efficacy are crucial. Control over particle size allows manufacturers to tailor the spray drying process to meet specific product requirements.

The Spray Drying Process

The spray drying process involves several key steps that must be carefully controlled to achieve the desired product characteristics.

Step 1: Atomization

Atomization is the first step in the spray drying process. It involves breaking down the liquid feed into fine droplets using an atomizer. This can be achieved through various methods, including rotary, nozzle, or ultrasonic atomization. The choice of method depends on the properties of the feed and the desired characteristics of the final product.

Methods of Atomization

Different methods of atomization offer unique advantages and are selected based on the feed’s properties and desired product outcomes. Rotary atomization is ideal for high-viscosity feeds and is known for producing droplets of uniform size. Nozzle atomization, whether pressure or pneumatic, is used for feeds that require high precision and control. Ultrasonic atomization is employed for delicate feeds where minimal shear stress is desired.

Factors Affecting Atomization

Several factors affect the atomization process, including feed viscosity, surface tension, and temperature. High-viscosity feeds may require additional energy to achieve proper atomization. Surface tension influences droplet formation, with lower surface tension aiding in the production of smaller droplets. Temperature plays a crucial role in viscosity and surface tension, impacting the overall efficiency of atomization.

Impact on Final Product

The atomization process directly impacts the final product’s characteristics, including particle size, moisture content, and overall quality. Precise control over atomization ensures that the resulting powder meets industry standards and customer expectations. Manufacturers must carefully calibrate the atomization process to achieve the desired balance between efficiency and product quality.

Step 2: Drying

Once the droplets are formed, they enter the drying chamber, where they are exposed to a stream of hot air. The temperature and airflow must be carefully controlled to ensure efficient drying without degrading the quality of the product. The moisture in the droplets evaporates quickly, leaving behind dry particles.

Temperature Control

Temperature control is crucial in the drying stage to prevent thermal degradation of sensitive materials. High temperatures can accelerate drying but may compromise the product’s integrity, especially in heat-sensitive applications. Conversely, low temperatures may result in incomplete drying, affecting the product’s stability and shelf life.

Airflow Dynamics

The airflow within the drying chamber must be optimized to ensure uniform drying of all particles. Laminar airflow provides consistent contact between the hot air and droplets, promoting efficient moisture removal. Turbulent airflow can lead to uneven drying, resulting in particles with varying moisture content and affecting the product’s quality.

Moisture Evaporation

Moisture evaporation is the core objective of the drying process, transforming liquid droplets into dry particles. Rapid moisture removal is essential to maintain the product’s nutritional and functional properties. The drying rate must be balanced to prevent over-drying, which can lead to brittle particles and potential product loss.

Step 3: Collection

After drying, the particles are collected using a cyclone separator or a bag filter. The collection system is designed to capture the dry particles while allowing the exhaust air to escape. The final product is usually a free-flowing powder with consistent particle size and moisture content.

Cyclone Separator Functionality

Cyclone separators are widely used in spray drying for their efficiency in collecting fine particles. They operate on centrifugal force, separating particles from the exhaust air based on differences in density. Cyclone separators are favored for their low maintenance and ability to handle large volumes of material.

Bag Filter Advantages

Bag filters provide an alternative collection method, particularly for capturing ultra-fine particles. They offer high collection efficiency and are ideal for applications requiring minimal product loss. Bag filters require regular maintenance to ensure optimal performance and prevent clogging.

Ensuring Product Consistency

Consistency in particle size and moisture content is critical for the final product’s quality and performance. The collection system must be designed to minimize product loss and prevent contamination. Manufacturers often implement quality control measures to verify product consistency, ensuring compliance with industry standards.

Applications of Spray Dryer

Spray drying is used in a wide range of industries due to its ability to produce high-quality powders with specific properties.

Food Industry

In the food industry, spray drying is used to produce powdered products such as milk, coffee, and flavorings. The process helps retain the nutritional value and flavor of the original product while extending its shelf life.

Dairy Product Applications

Spray drying is extensively used in the production of dairy products like milk powder and whey protein. The process ensures the preservation of essential nutrients while providing a convenient, shelf-stable product. Milk powder produced through spray drying is widely used in infant formula and as an ingredient in various food products.

Coffee and Beverage Powders

Instant coffee and beverage powders benefit significantly from spray drying, which helps retain flavor and aroma. The process transforms liquid coffee extract into a soluble powder, making it convenient for consumers. Beverage powders, including tea and fruit drinks, are also produced using spray drying to ensure quick solubility and long shelf life.

Flavorings and Spices

Spray drying is employed to create powdered flavorings and spices, preserving their aromatic compounds. The technique allows for the production of free-flowing powders that are easy to handle and incorporate into food products. Spray-dried flavorings are used in soups, sauces, and snack foods, offering consistent taste and aroma.

Pharmaceutical Industry

The pharmaceutical industry relies on spray drying to produce fine powders for inhalation, encapsulation, and other applications. The ability to control particle size and moisture content is crucial for ensuring the efficacy and stability of pharmaceutical products.

Inhalation Formulations

Spray drying is used to create fine powders for inhalation therapies, such as asthma and COPD medications. The process ensures the production of particles with uniform size, essential for effective drug delivery to the lungs. Inhalation formulations benefit from spray drying’s ability to produce particles with optimal aerodynamic properties.

Encapsulation Applications

Encapsulation of active pharmaceutical ingredients (APIs) is facilitated by spray drying, providing protection and controlled release. The technique allows for the creation of microencapsulated particles, enhancing the stability and bioavailability of sensitive APIs. Encapsulation is crucial for improving the therapeutic efficacy and patient compliance of pharmaceuticals.

Controlled Release Systems

Spray drying enables the development of controlled release systems, allowing for sustained drug release over time. The process can produce matrix or reservoir-type particles, offering flexibility in designing release profiles. Controlled release systems are essential for improving patient adherence and reducing dosing frequency.

Chemical Industry

In the chemical industry, spray drying is used to produce catalysts, pigments, and other fine chemicals. The process allows for the production of uniform particles with specific properties, making it an essential technique for many chemical applications.

Catalyst Production

Spray drying is employed in the production of catalysts, which require precise control over particle size and surface area. The process ensures the creation of catalysts with consistent properties, essential for efficient chemical reactions. Catalysts produced through spray drying are used in various applications, including petrochemicals and environmental protection.

Pigment Manufacturing

Pigment production benefits from spray drying’s ability to create uniform particles with vibrant color properties. The technique is used to produce pigments for paints, coatings, and inks, ensuring consistent color quality. Spray-dried pigments offer excellent dispersion and stability, essential for high-performance applications.

Fine Chemical Production

Spray drying is used to produce fine chemicals with specific particle characteristics, which are crucial for various industrial applications. The process allows for the precise control of particle size and morphology, which is essential for chemical performance. Fine chemicals produced through spray drying are used in electronics, pharmaceuticals, and agriculture.

Other Industries

Beyond food, pharmaceuticals, and chemicals, spray drying finds applications in industries such as ceramics, detergents, and biofuels. Its versatility and efficiency make it a valuable tool for producing dry powders across various sectors.

Ceramics and Materials

Spray drying is used in the ceramics industry to produce powders for the manufacturing of tiles and advanced ceramics. The process ensures uniform particle size and distribution, which is essential for high-quality ceramic products. Spray-dried ceramic powders offer improved flowability and compaction, enhancing manufacturing efficiency.

Detergent Production

Detergent manufacturing benefits from spray drying’s ability to produce free-flowing powders with a consistent composition. The process allows for the incorporation of various ingredients, including surfactants and enzymes, into a single product. Spray-dried detergents provide excellent solubility and performance in various washing conditions.

Biofuel and Biomass Applications

Spray drying is employed in the production of biofuels and biomass-derived products, offering efficient moisture removal. The process is used to produce powders from biomass slurries, facilitating transportation and storage. Spray-dried biofuels offer potential as sustainable energy sources, reducing reliance on fossil fuels.

Advantages of Spray Drying

Spray drying offers several advantages that make it a preferred method for producing dry powders.

High Efficiency

The spray drying process is highly efficient, allowing for the rapid transformation of liquids into dry powders. This efficiency reduces production time and energy consumption.

Rapid Drying Process

The rapid drying process of spray drying minimizes the time required to transform liquid feeds into powders. This quick turnaround is beneficial for high-volume production, ensuring that manufacturers can meet market demand efficiently. The reduction in drying time also contributes to lower energy consumption, making the process more cost-effective.

Energy Efficiency

Spray drying’s energy efficiency is a significant advantage, particularly in industries where energy costs are a major concern. By optimizing temperature and airflow, manufacturers can reduce energy usage while maintaining product quality. The implementation of energy-efficient technologies further enhances the sustainability of the spray drying process.

Cost-Effectiveness

The cost-effectiveness of spray drying is attributed to its ability to produce high-quality powders at a lower cost compared to alternative drying methods. The process’s efficiency and scalability contribute to reduced operational costs, making it an attractive option for manufacturers. The ability to produce consistent products with minimal waste further enhances its economic viability.

Consistent Product Quality

Spray drying ensures consistent product quality by allowing precise control over particle size, moisture content, and other properties. This consistency is crucial for meeting industry standards and customer expectations.

Precision in Particle Control

The precision in particle control offered by spray drying is essential for producing products that meet specific industry requirements. Consistent particle size and moisture content are critical for applications in pharmaceuticals, food, and chemicals. The ability to tailor the process to achieve desired product characteristics ensures that manufacturers can deliver high-quality products consistently.

Meeting Industry Standards

Meeting industry standards is a priority for manufacturers, and spray drying provides the control necessary to achieve this goal. The process’s ability to produce powders with uniform properties ensures compliance with regulatory requirements. Quality assurance measures are often implemented to verify that products meet the necessary standards and specifications.

Customer Satisfaction

Customer satisfaction is enhanced by the consistent quality of products produced through spray drying. The ability to deliver powders with reliable performance and stability builds trust with consumers and industry partners. Manufacturers can leverage spray drying’s precision to create products that meet customer expectations and foster brand loyalty.

Versatility

Spray drying is a versatile process that can be adapted to handle a wide range of feed materials and produce powders with specific characteristics. This versatility makes it suitable for various industries and applications.

Adaptability to Different Feeds

The adaptability of spray drying to different feeds is a significant advantage, allowing manufacturers to process a wide variety of materials. Whether dealing with high-viscosity feeds or heat-sensitive compounds, spray drying can be customized to achieve optimal results. This flexibility makes it an attractive option for industries with diverse product lines.

Customization of Product Properties

The customization of product properties is a key benefit of spray drying, enabling manufacturers to tailor powders to meet specific application needs. Control over particle size, morphology, and moisture content allows for the creation of powders with desired characteristics. This capability is particularly valuable in industries such as pharmaceuticals and chemicals, where product performance is critical.

Broad Range of Applications

The broad range of applications for spray drying highlights its versatility, with uses spanning food, pharmaceuticals, chemicals, and more. The process’s ability to produce high-quality powders with specific properties makes it suitable for diverse industries. Manufacturers can leverage spray drying’s versatility to innovate and expand their product offerings.

Improved Shelf Life

By removing moisture from the product, spray drying extends the shelf life of the final powder. This is particularly important in the food and pharmaceutical industries, where product stability is crucial.

Moisture Removal Benefits

Moisture removal is a primary benefit of spray drying, contributing to the extended shelf life of powdered products. By reducing water activity, the process inhibits microbial growth and spoilage, enhancing product stability. This advantage is particularly valuable in food and pharmaceutical applications, where shelf life is a critical consideration.

Preservation of Nutritional and Functional Properties

Preservation of nutritional and functional properties is a key advantage of spray drying, ensuring that products retain their intended benefits. The gentle drying process minimizes nutrient degradation, maintaining the quality of food and pharmaceutical products. Functional properties, such as solubility and dispersibility, are also preserved, ensuring optimal product performance.

Extended Product Stability

Extended product stability is achieved through spray drying’s ability to produce powders with low moisture content. Stable powders are less susceptible to chemical and physical changes, ensuring consistent quality over time. This stability is essential for maintaining customer satisfaction and reducing product returns.

Challenges and Considerations

While spray drying offers numerous benefits, it also presents some challenges that must be addressed to ensure optimal results.

Feed Properties

The properties of the liquid feed, such as viscosity and solids content, can significantly impact the spray drying process. Careful consideration of these factors is essential for achieving the desired product characteristics.

Viscosity Challenges

Viscosity is a significant challenge in spray drying, as high-viscosity feeds can be difficult to atomize effectively. Ensuring proper atomization requires careful selection of atomization methods and equipment. Manufacturers must evaluate feed viscosity and make necessary adjustments to achieve optimal atomization and drying.

Solids Content Considerations

Solids content in the liquid feed influences the drying process, affecting the final product’s properties. High solids content can lead to increased drying times and potential clogging of equipment. Manufacturers must balance solids content to ensure efficient drying while maintaining product quality.

Feed Temperature and Stability

Feed temperature and stability are critical factors in spray drying, impacting atomization and drying efficiency. Temperature affects feed viscosity and surface tension, influencing droplet formation and evaporation rates. Ensuring feed stability throughout the process is essential for consistent product quality.

Equipment Selection

Choosing the right equipment is critical for the success of the spray drying process. Factors such as atomizer type, drying chamber design, and collection system must be carefully evaluated to ensure efficient drying and high product quality.

Atomizer Selection

Selecting the appropriate atomizer is a crucial consideration in spray drying, as it directly impacts droplet formation and product characteristics. Manufacturers must evaluate the specific requirements of their feed and product to choose the most suitable atomizer type. Factors such as feed viscosity, desired droplet size, and production capacity influence atomizer selection.

Drying Chamber Design

The design of the drying chamber plays a vital role in the efficiency and effectiveness of the spray drying process. Chamber design affects airflow patterns, temperature distribution, and drying time. Manufacturers must consider these factors to optimize drying performance and ensure consistent product quality.

Collection System Efficiency

The efficiency of the collection system is essential for capturing dry particles and minimizing product loss. Manufacturers must evaluate the suitability of cyclone separators, bag filters, or other collection methods based on their specific application needs. Proper collection system design ensures high product yield and reduces operational costs.

Environmental Impact

Spray drying can have environmental implications, particularly in terms of energy consumption and emissions. Implementing energy-efficient practices and utilizing sustainable technologies can help mitigate these impacts.

Energy Consumption Concerns

Energy consumption is a primary environmental concern in spray drying, with high energy demands for heating and airflow. Manufacturers can address this issue by optimizing process parameters and implementing energy-efficient technologies. Reducing energy consumption not only benefits the environment but also lowers operational costs.

Emission Reduction Strategies

Reducing emissions is a critical consideration for minimizing the environmental impact of spray drying. Manufacturers can implement strategies such as using cleaner fuels, optimizing combustion processes, and installing emission control devices. Emission reduction efforts contribute to sustainable production practices and regulatory compliance.

Sustainable Technology Integration

Integrating sustainable technologies into spray drying operations can enhance environmental performance. Technologies such as heat recovery systems, renewable energy sources, and advanced control systems offer opportunities for reducing environmental impact. Manufacturers can leverage these innovations to achieve sustainable production goals and improve their environmental footprint.

Conclusion

Spray drying is a powerful technique that plays a vital role in various industries. Its ability to produce high-quality powders with specific properties makes it an invaluable tool for manufacturers. By understanding the spray dryer principle and the intricacies of the spray drying process, businesses can harness its potential to create innovative products and meet the demands of a competitive market. Whether in the food, pharmaceutical, or chemical industry, spray drying continues to be a cornerstone of modern production techniques.

Future Trends and Innovations

The future of spray drying holds exciting possibilities, with ongoing research and development driving innovation. Advancements in atomization technology, process control, and sustainable practices offer new opportunities for enhancing spray drying efficiency and performance. Manufacturers can anticipate continued growth and evolution in the application of spray drying across diverse industries.

Embracing Sustainability

Sustainability is an increasingly important consideration for manufacturers using spray drying, with a growing emphasis on reducing environmental impact. Embracing sustainable practices, such as energy-efficient technologies and waste reduction strategies, can enhance the environmental performance of spray drying operations. Manufacturers can leverage sustainability as a competitive advantage, meeting market demands for eco-friendly products.

Meeting Industry Challenges

As industries face evolving challenges, spray drying remains a versatile and adaptable solution. The ability to produce high-quality powders with precise properties positions spray drying as a valuable tool for addressing industry needs. Manufacturers can rely on spray drying’s versatility to overcome challenges and seize new opportunities in a dynamic market landscape.