Spray drying is a critical process used across various industries, including food production, pharmaceuticals, chemical manufacturing, and more. It involves transforming a liquid feed into a free-flowing powder through rapid evaporation of moisture. When considering purchasing a spray dryer for your business, several factors come into play. This guide will help you navigate the process effectively, ensuring you select the most suitable spray dryer for your specific needs.

Understanding Your Requirements

Before diving into the market, it’s crucial to understand what your business requires from a spray dryer. Consider the following aspects:

1. Material Characteristics: What is the nature of the material you plan to dry? Factors like viscosity, thermal sensitivity, and particle size distribution can influence the type of spray dryer you need.

2. Production Capacity: How much product do you need to produce daily or hourly? This will determine the size and capacity of the dryer required.

3. Moisture Content: What is the initial moisture level of the product and what is the desired final moisture content?

4. Dust Emission Standards: Are there any environmental regulations you must comply with regarding dust emissions?

5. Budget: How much are you willing to spend? Consider not just the initial purchase price but also ongoing maintenance costs.

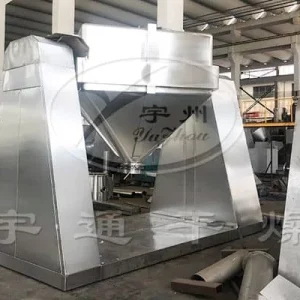

Types of Spray Dryers

Spray dryers come in various types, each suited for different applications:

1. Pressure Nozzle Atomizers: These are ideal for handling high viscosity materials and require less air to operate efficiently.

2. Centrifugal Atomizers: Suitable for medium to low viscosity materials, these atomizers can handle high capacities and produce fine particle sizes.

3. Air Atomizers: They work best for low viscosity materials and can be adjusted for different particle sizes.

4. Fluid Bed Spray Dryers: Used for sensitive materials that require gentle treatment during the drying process.

Key Components and Features

A typical spray dryer consists of several components:

Atomizer: Converts the liquid into droplets.

Drying Chamber: Where the actual drying takes place.

Air Handling System: Controls the temperature and flow rate of the drying air.

Dust Collection System: Removes dried particles from the exhaust air.

Features to look for include energy efficiency, ease of cleaning, and automation capabilities.

Selection Criteria

When choosing a spray dryer, consider:

1. Efficiency and Energy Consumption: Look for models that optimize energy usage without compromising performance.

2. Maintenance and Durability: Opt for a dryer that requires minimal maintenance and is built to last.

3. Flexibility: Can the machine handle different types of materials and adjust to varying production demands?

4. Safety Features: Ensure the dryer meets all safety standards to protect operators and the environment.

Vendors and Manufacturers

Research different vendors and manufacturers. Companies like GEA, Bühler, and Niro are well-known for their high-quality spray drying equipment. Check for warranties, customer support, and the availability of spare parts.

Cost and Financing

Consider both upfront costs and long-term expenses. Financing options may be available through the vendor or third-party financial institutions.

Installation and Training

Ask about installation services and training programs. Proper installation and operator training are crucial for optimal performance and safety.

Investing in a spray dryer is a significant decision that can impact your business’s productivity and profitability. By carefully evaluating your needs, understanding the different types of dryers available, and selecting a reputable manufacturer, you can ensure that your investment leads to improved efficiency and quality in your production process.

Remember, the right spray dryer should not only meet your current requirements but also accommodate potential future growth. Conduct thorough research, seek expert advice, and compare quotes before making your final decision.