Table of Contents

Product Detail

Basic principle

Granule or pellet solid materials are fed into the fluidized bed dryer through the feeder. Filtrated clean air is heated and charged onto the bottom of the fluidized bed to contact the solid materials on the distributing plate, where fluidization can be reached and the heat exchange between solid and air can be achieved. After being dried, the products are discharged from the outlet. Waste gas is discharged from the top of the fluidized bed, and the cyclone separator or bag dust remover recovers powder materials.

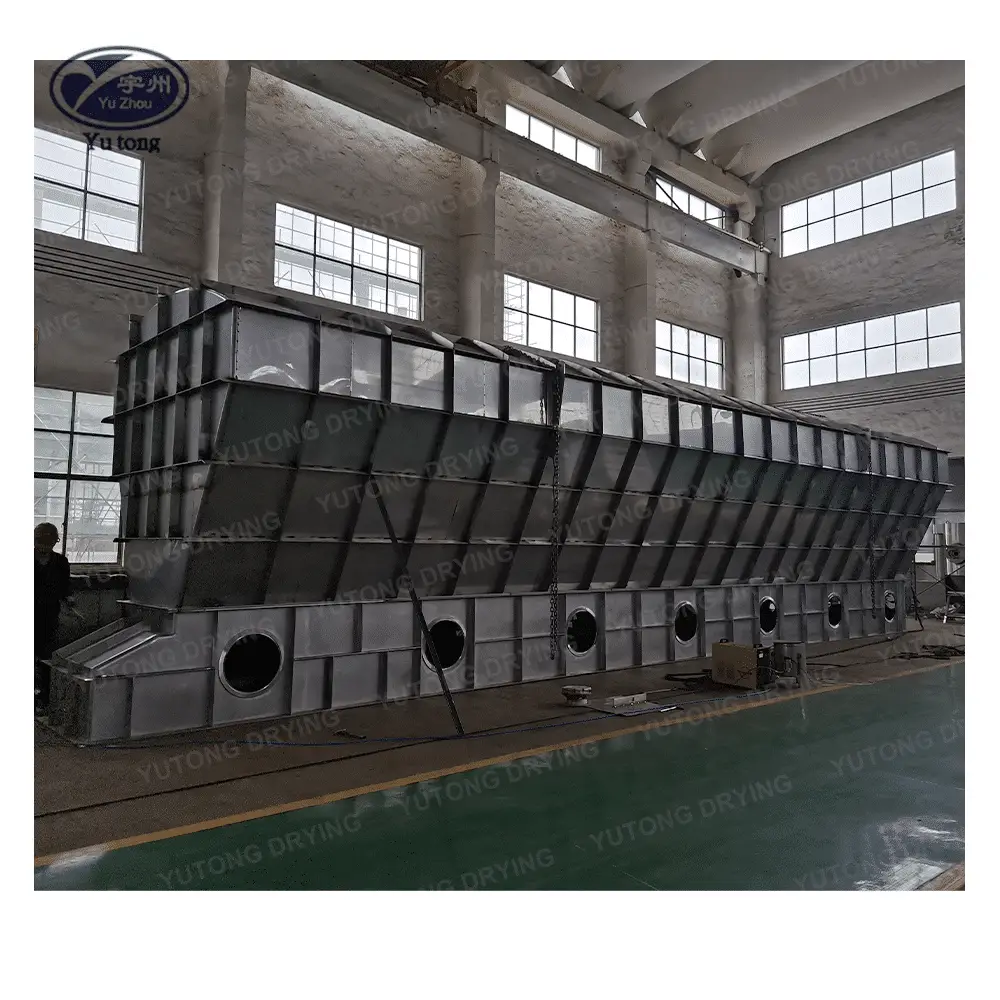

Description of Horizontal Fluidizing Dryer

Fluidizing dryer is mostly used for drying diferent kind of Vanilin product. We already have lots of different

customers of Vanillion in China, some are the top leading enterprise in the line.

Main Features

1) This fluidized dryer operates under closed negative pressure without dust explosion.

2) Using anti-static filter materials, our fluidized drying machine operates safely and stably

Specifications

|

Type

|

Bed area(m³)

|

Drying

capacity (water Kg/h) |

Power(Kw)

|

Air pressure(Pa)

|

Air volume(m³/H)

|

Air intake

temp(℃) |

Material

discharge temp(℃) |

Heating energy consumption

Steam(Kg/h) |

Heating energy consumption Elec power(kw)

|

|

XF-10A

|

0.25

|

10~15

|

5.5

|

4900

|

2300

|

60~140 |

40~80 |

50 |

30 |

|

XF-10B

|

0.25

|

4

|

3800

|

2300

|

|||||

|

XF-20A

|

0.5

|

20~25 |

7.5

|

5000

|

3100

|

100 |

60 |

||

|

XF-20B

|

0.5

|

5.5

|

3500

|

3100

|

|||||

|

XF-30A

|

1

|

30~45 |

15

|

6000

|

4200

|

150 |

90 |

||

|

XF-30B

|

1

|

11

|

4700

|

4200

|

|||||

|

XF-50A

|

2

|

50~80 |

22

|

7400

|

6000

|

250 |

150 |

||

|

XF-50B

|

2

|

18.5

|

5900

|

6000

|

Applications

Applicable Industries:

Chemicals Processing, Plastics Processing, Food Processing