Table of Contents

Product Detail

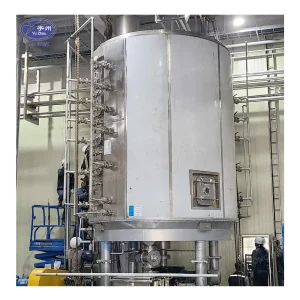

In today’s competitive industrial landscape, the demand for efficient and reliable drying equipment is ever-increasing. The double-cone vacuum dryer has emerged as a popular choice for industries ranging from pharmaceuticals to chemicals, food processing, and beyond. This article delves into the world of vacuum dryers, with a particular focus on manufacturers in India, exploring the advantages, applications, and considerations when choosing the right equipment for your needs.

Understanding Double Cone Vacuum Dryers

Double cone vacuum dryers are specialized equipment designed to dry heat-sensitive materials without causing thermal degradation. They operate under vacuum conditions, which lower the solvent’s boiling point and enhance the drying process. This method is particularly effective for materials that require gentle handling and precise drying.

The Science Behind Vacuum Drying

Vacuum drying is based on the principle that liquids’ boiling points decrease under reduced pressure. By creating a vacuum, the double-cone dryer allows solvents to evaporate at much lower temperatures. This not only speeds up the drying process but also protects sensitive compounds from heat damage, preserving their quality and functionality.

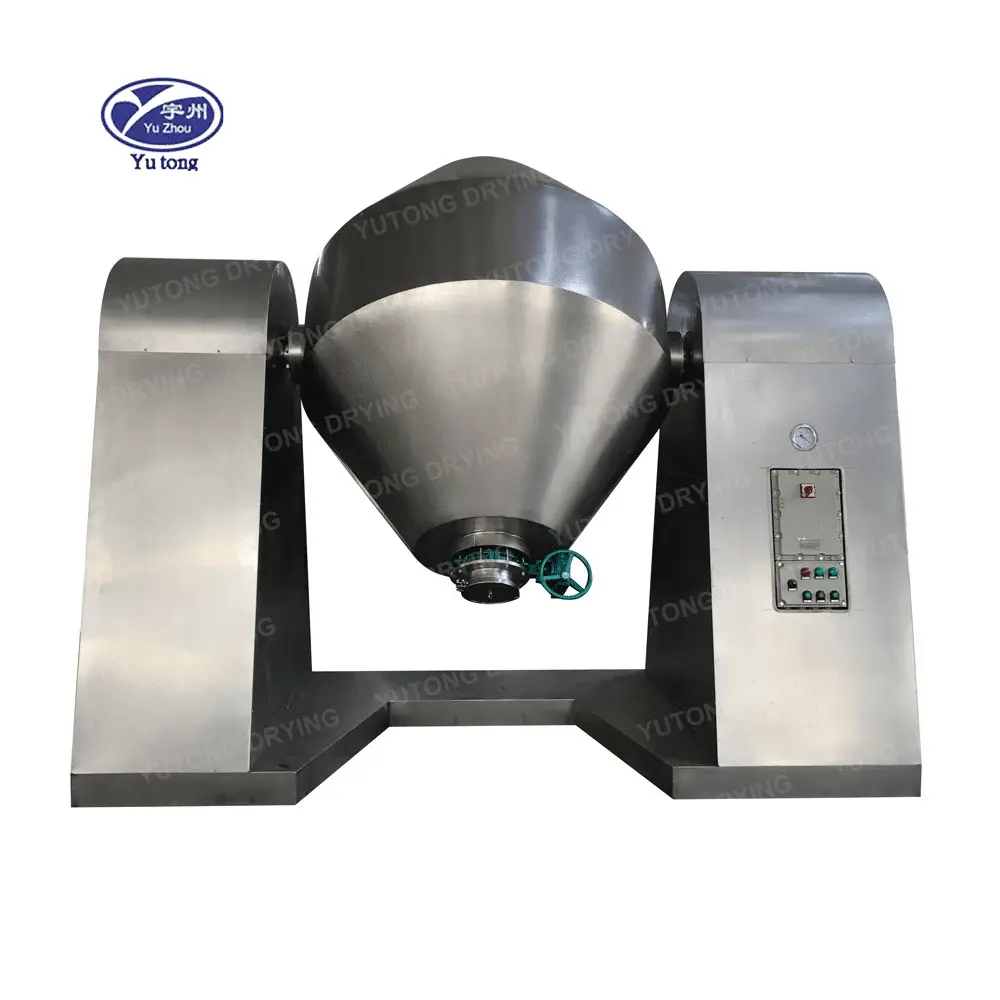

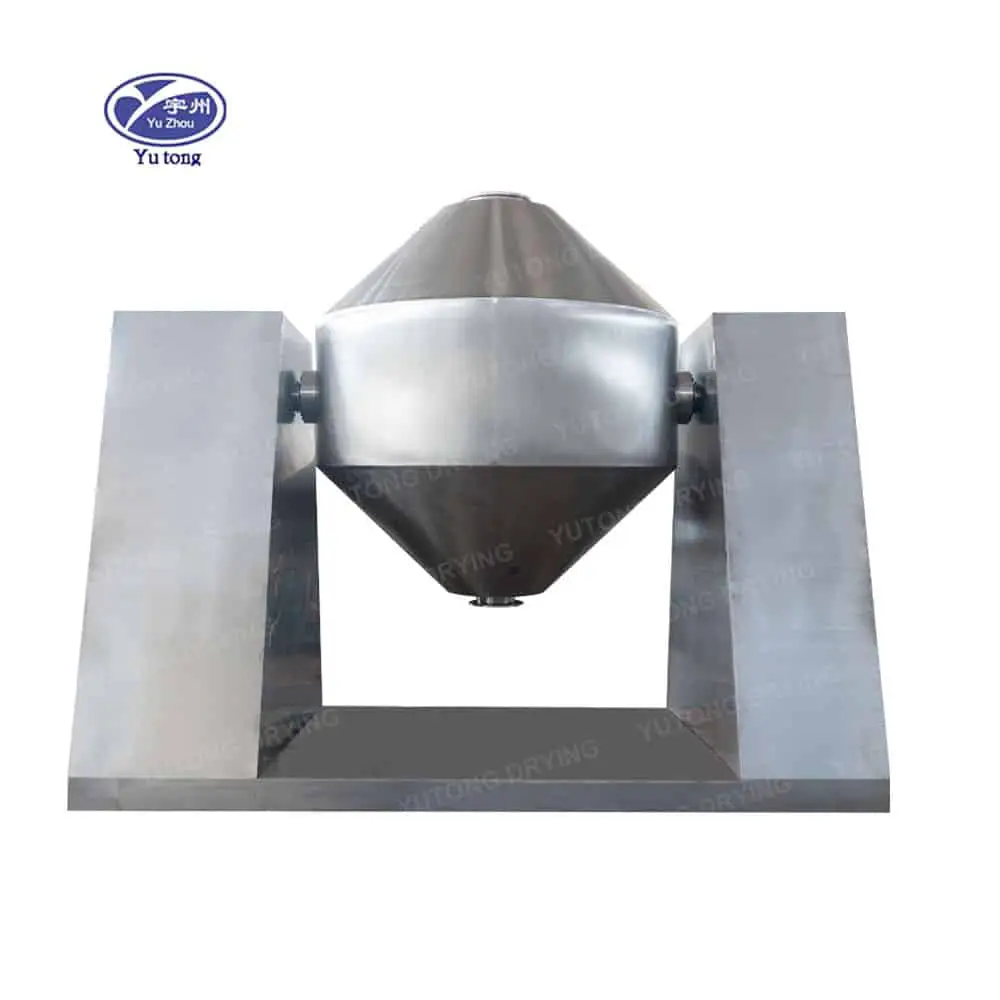

Design and Structure

The double-cone design is a unique feature that sets these dryers apart. The shape allows for maximum exposure of the material to the heated surface, ensuring uniform drying. The rotating motion further aids in mixing, preventing any potential for hotspots that could degrade the material. This design is integral to achieving consistent and high-quality drying results.

Operational Mechanisms

Operating a double-cone vacuum dryer involves a controlled rotation within a sealed environment. The vacuum system efficiently removes moisture, while the gentle tumbling action ensures even heat distribution. This operational mechanism is crucial for maintaining the integrity and efficacy of delicate materials, making them indispensable in industries like pharmaceuticals and food processing.

Advantages of Double Cone Vacuum Dryers

Double-cone vacuum dryers offer several benefits that make them a preferred choice for various industries:

Enhanced Efficiency

Efficiency is a hallmark of double-cone vacuum dryers. The vacuum environment significantly reduces drying times, which speeds up production and conserves energy. Reduced energy consumption translates to lower operational costs, making these dryers a cost-effective solution for large-scale operations.

Superior Quality Preservation

One of the standout advantages is the ability to preserve the integrity, potency, and quality of heat-sensitive materials. The gentle drying method ensures that essential properties are retained, which is critical in industries where product quality directly impacts efficacy, such as pharmaceuticals and nutraceuticals.

Versatility Across Industries

The versatility of double-cone vacuum dryers makes them suitable for a wide range of applications. Whether it’s the precise drying of APIs in pharmaceuticals, the careful dehydration of food products, or the efficient processing of chemical compounds, these dryers offer unparalleled flexibility to meet diverse industrial needs.

Safety and Environmental Benefits

Safety is a top priority in industrial processes, and double-cone vacuum dryers excel in this aspect. They minimize the risk of oxidation and contamination, ensuring a safe drying process. Additionally, the reduced energy requirements align with sustainability goals, reducing the environmental footprint of industrial operations.

Space Efficiency

Another significant advantage of double-cone vacuum dryers is their compact design. For facilities with limited space, these dryers offer high-capacity drying without a large footprint. This space-saving feature is particularly valuable in urban or constrained environments where maximizing available space is crucial.

Key Manufacturers in India

India is home to several reputable manufacturers of double-cone vacuum dryers, offering a range of options to cater to diverse industrial needs. Here are some of the leading manufacturers:

Prominent Manufacturers in Gujarat

Gujarat is a hub for industrial equipment manufacturing, including vacuum trays and double-cone vacuum dryers. Manufacturers in this region are known for their innovation, quality, and competitive pricing. They offer a variety of models with customizable features to suit specific requirements. The state’s strategic location and robust infrastructure also contribute to its efficiency and reliability.

Leading Producers in Mumbai

Mumbai, a major industrial city, hosts several manufacturers specializing in vacuum tray dryers. These manufacturers provide solutions that adhere to international quality standards, ensuring reliable performance and durability. With access to a vast pool of skilled labor and advanced technology, Mumbai-based manufacturers are at the forefront of delivering cutting-edge drying solutions.

Noteworthy Suppliers Across India

Beyond Gujarat and Mumbai, other regions in India also boast noteworthy manufacturers of rotary vacuum dryers. These suppliers leverage local expertise and global insights to produce equipment that meets the rigorous demands of modern industries. Their commitment to quality and customer satisfaction ensures that businesses receive dryers that are both efficient and durable.

Factors to Consider When Choosing a Manufacturer

Selecting the proper manufacturer for your double-cone vacuum dryer is crucial to ensure optimal performance and longevity. Here are some factors to consider:

Reputation and Industry Experience

A manufacturer’s reputation and industry experience are key indicators of their reliability. Companies with a proven track record have a history of delivering high-quality products and are more likely to provide equipment that meets your specific needs. Extensive experience often translates into better customer service and support.

Customization and Flexibility

Look for manufacturers that offer customizable solutions to meet your specific needs. Tailoring features such as size, capacity, and operational controls ensure that the equipment can seamlessly integrate into your existing processes. Customization enhances efficiency and can lead to significant operational improvements.

Compliance with Quality Standards

Ensure that the equipment meets international quality standards and certifications. Compliance with these standards is crucial for safety, reliability, and performance. Manufacturers who adhere to stringent quality controls are more likely to produce equipment that is robust and capable of withstanding industrial demands.

Support and Maintenance Services

Reliable after-sales support and service are essential for maintaining equipment performance. Choose manufacturers that offer comprehensive maintenance packages and responsive customer service. This support is vital for addressing any operational issues promptly and minimizing downtime.

Competitive Pricing and Value

Compare prices from different manufacturers to ensure you get the best value for your investment. While cost is a significant consideration, it should not be the sole deciding factor. Evaluate the overall value proposition, including quality, support, and long-term benefits, to make an informed decision.

Vacuum Dryer Pricing in India

The cost of vacuum dryers in India varies based on factors such as design, capacity, and features. It’s essential to assess your budget and requirements to find a solution that offers the best balance of cost and functionality.

Price Range for Vacuum Tray Dryers

Vacuum tray dryers are available at a range of price points, depending on their size and specifications. Manufacturers in India offer competitive pricing while maintaining high standards of quality and performance. Understanding your operation’s specific requirements will help you choose a model that aligns with your budget and drying needs.

Factors Influencing Vacuum Dryer Costs

The price of vacuum dryers in India is influenced by factors such as technology, materials, and manufacturing processes. Investing in a high-quality vacuum dryer can yield significant long-term benefits in terms of efficiency and product quality. When evaluating options, consider the total cost of ownership, including maintenance and operational efficiency.

Cost-Benefit Analysis

Conducting a cost-benefit analysis can provide valuable insights into the financial implications of your purchase. Weighing the initial investment against potential savings in energy and increased productivity will help determine the most economically viable option for your business.

Applications of Double Cone Vacuum Dryers

Double-cone vacuum dryers find applications across various industries due to their versatility and effectiveness. Some typical applications include:

Pharmaceutical Industry Applications

In the pharmaceutical industry, these dryers are essential for the drying of active pharmaceutical ingredients (APIs) and other sensitive materials. The precise control over drying conditions ensures that the integrity and efficacy of the compounds are preserved, which is critical for producing safe and effective medications.

Chemical Industry Use Cases

For the chemical industry, double-cone vacuum dryers efficiently dry chemical compounds and intermediates. Their ability to handle volatile and heat-sensitive materials with precision makes them indispensable for producing high-quality chemical products.

Food Processing Industry Benefits

Preserving flavors, nutrients, and quality of food products is paramount in food processing. Double-cone vacuum dryers excel at gently removing moisture without compromising taste, texture, or nutritional value, making them ideal for dehydrating a variety of food items.

Biotechnology and Life Sciences

These dryers benefit the biotechnology sector by drying biotech products and enzymes. The gentle drying process ensures that the biological activity of enzymes and other bioproducts is maintained, which is crucial for research and production in life sciences.

Conclusion

Double-cone vacuum dryers are an invaluable asset for industries seeking efficient and reliable drying solutions. With a variety of manufacturers in India offering high-quality equipment, businesses can find the perfect match to meet their specific needs. By considering factors such as reputation, customization, and pricing, you can make an informed decision and invest in equipment that enhances your production processes.

Whether you’re in pharmaceuticals, chemicals, food processing, or another industry, a double-cone vacuum dryer can elevate your operations and ensure the consistent quality of your products. Choose the proper manufacturer today and experience the benefits of advanced drying technology. Investing in a reliable and efficient drying solution not only boosts productivity but also enhances the overall quality of your output, positioning your business for tremendous success in the competitive industrial landscape.

Specifications

|

Model

|

100

|

500

|

1000

|

1500

|

2000

|

5000

|

|

Volume (L)

|

100

|

500

|

1000

|

15000

|

2000

|

5000

|

|

Maximum Loading Volume (L)

|

40

|

200

|

400

|

600

|

800

|

2000

|

|

Maximum Loading Capacity (kg)

|

20

|

100

|

200

|

300

|

400

|

1000

|

|

Rotating Speed (rpm)

|

3~13

|

6

|

5

|

4

|

||

|

Motor Power (k w)

|

0.75

|

1.5

|

3

|

4

|

5.5

|

15

|

|

Floor Area (mm)

|

2160 × 800

|

2350× 800

|

2860 × 1300

|

3060 × 1300

|

3260 × 1400

|

4400 × 2500

|

|

Rotation Height (mm)

|

1750

|

2250

|

2800

|

2940

|

2990

|

4200

|

|

Design Pressure In Container (MPa)

|

-0.09 to 0.096

|

|||||

|

Interlayer Design Pressure (MPa)

|

≤ 0.3

|

|||||

|

Weight (kg)

|

800

|

1200

|

2800

|

3300

|

3600

|

8600

|

Applications

Applicable Industries: Machinery Repair Shops, Food & Beverage Factory, Farms, Retail, Food Shop, Energy & Mining, Food & Beverage Shops