Table of Contents

Product Detail

Precision and efficiency are paramount in laboratory processing. When it comes to drying powders, the double-cone vacuum dryer stands out as a versatile and effective solution. This article delves into the intricacies of the double-cone vacuum dryer, exploring its applications, benefits, and operational principles. Whether you’re working with pharmaceuticals, chemicals, or food products, understanding this equipment can significantly enhance your laboratory processes.

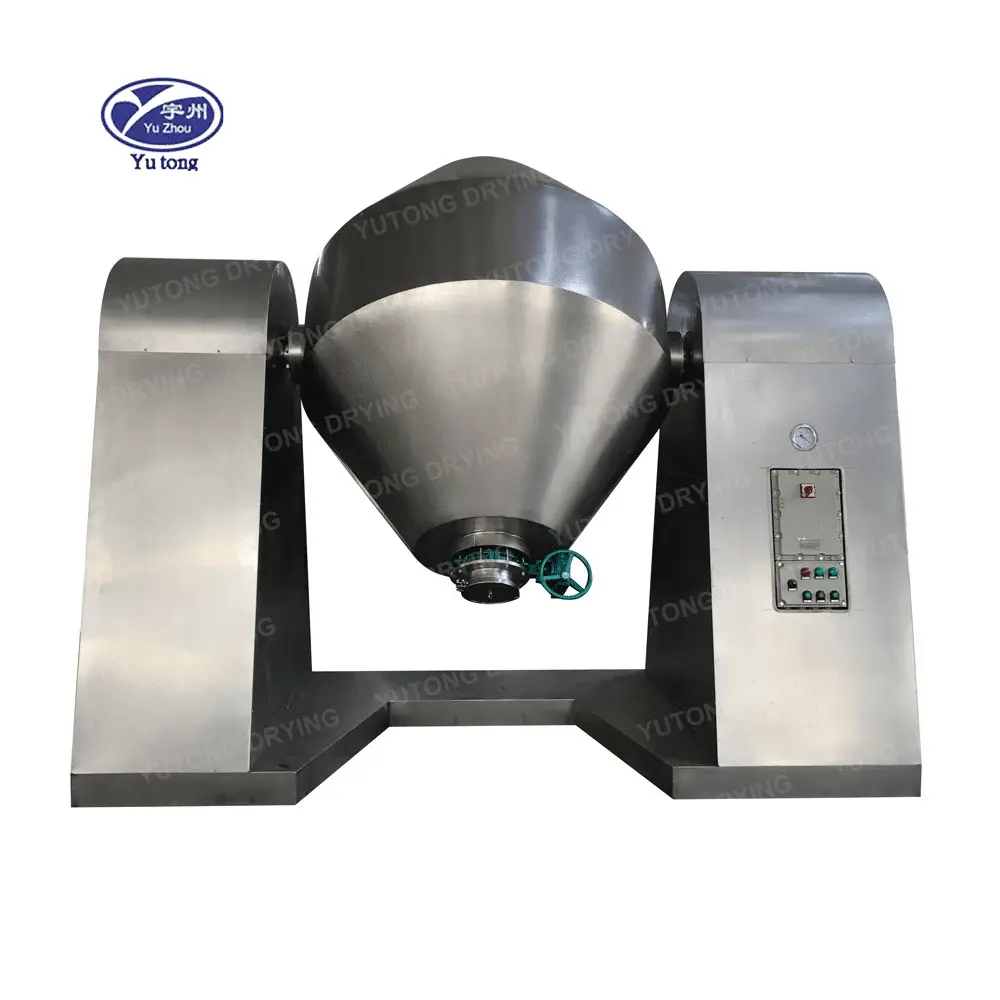

Understanding the Double Cone Vacuum Dryer

The double-cone vacuum dryer is a sophisticated piece of equipment designed for drying powdery substances. Its unique design allows for uniform drying under vacuum conditions, which is ideal for heat-sensitive materials. But what makes this dryer so effective?

Key Features and Design

The double cone design is not just for aesthetic appeal; it plays a crucial role in the drying process. The two conical sections allow for thorough mixing and uniform drying of the material. This design facilitates efficient heat transfer and reduces drying time. The symmetrical nature of the cones ensures that the material is constantly moving, providing consistent exposure to the drying medium.

- Material Compatibility: The double-cone vacuum dryer is compatible with a wide range of materials, including pharmaceuticals, chemicals, and food powders. Its versatility makes it a popular choice across various industries. The use of stainless steel or other inert materials in construction also ensures that it does not react with sensitive substances, maintaining the purity of the products.

- Vacuum Environment: By creating a vacuum, this dryer significantly lowers the boiling point of water and solvents, allowing for drying at lower temperatures. This is particularly beneficial for heat-sensitive materials. The vacuum environment also helps to prevent the oxidation of products, preserving their quality and integrity.

- Energy Efficiency: The vacuum environment contributes to energy efficiency, as it requires less heat to achieve the desired drying effect. This not only reduces operational costs but also minimizes the environmental footprint of laboratory operations, aligning with sustainable practices.

Advanced Technology Integration

Modern double-cone vacuum dryers incorporate advanced technology to enhance their functionality. Automated control systems allow for precise regulation of temperature, pressure, and mixing speed, ensuring optimal drying conditions. Integration with laboratory management software can facilitate real-time monitoring and data logging, providing insights for process optimization.

Design Adaptability

The double-cone vacuum dryer’s design is adaptable, making it suitable for a variety of laboratory setups. Customizable features such as size, capacity, and construction material cater to specific laboratory needs. This flexibility ensures that laboratories can tailor the equipment to fit their unique operational requirements.

Applications in the Laboratory

Laboratories across different fields can benefit from the use of a double-cone vacuum dryer. Here are some typical applications:

Pharmaceutical Applications

Maintaining the integrity and potency of active ingredients is crucial in the pharmaceutical industry. The double-cone vacuum dryer provides gentle drying conditions, preserving the quality of sensitive pharmaceutical powders. This is essential for ensuring that medications meet stringent regulatory standards and deliver therapeutic benefits effectively.

Chemical Processing

Chemical laboratories often deal with substances that require precise moisture content control. The double-cone vacuum dryer ensures consistent and uniform drying, which is essential for accurate chemical processing. Proper drying is vital to prevent chemical reactions that could alter the substance’s properties or lead to hazardous situations.

Food Industry

For food laboratories, the double-cone vacuum dryer is an invaluable tool for drying spices, flavors, and other food powders. It helps retain the aroma and nutritional value of food products by preventing exposure to high temperatures. The dryer preserves delicate flavors and essential nutrients, enhancing the quality of the final product.

Biotechnology and Research

The double-cone vacuum dryer is used to prepare samples and reagents in biotechnology and research labs. Its ability to handle small batches efficiently makes it ideal for experimental setups where precision is key. This versatility supports a wide range of research activities, from drug development to material science.

Environmental and Agricultural Studies

The equipment is also beneficial in environmental and agricultural studies, where moisture content analysis is critical. By providing accurate drying, the double-cone vacuum dryer aids in determining soil properties, evaluating crop quality, and conducting environmental assessments.

Advantages Over Other Drying Methods

While there are several drying methods available, the double-cone vacuum dryer offers distinct advantages:

Uniform Drying

The design of the double-cone vacuum dryer ensures that all parts of the material are exposed to uniform heat, resulting in consistent drying. This is a significant advantage over conventional drying methods, which may lead to uneven moisture distribution. Uniform drying is crucial for maintaining product quality and ensuring that subsequent processing steps are practical.

Reduced Drying Time

The vacuum environment accelerates the drying process, reducing the time required to achieve optimal dryness. This is not only efficient but also cost-effective, particularly in a laboratory setting where time is of the essence. Faster drying times increase throughput and productivity, allowing laboratories to meet demanding schedules.

Enhanced Product Quality

The double-cone vacuum dryer minimizes the risk of thermal degradation by drying at lower temperatures. This is crucial for preserving the quality and efficacy of sensitive materials. Enhanced product quality translates to better performance, whether in pharmaceuticals, food, or chemical applications.

Operational Flexibility

The double-cone vacuum dryer offers operational flexibility, allowing laboratories to adjust parameters to suit different materials and processes. This adaptability is beneficial for laboratories that handle diverse products, enabling them to switch between different drying requirements seamlessly.

Safety and Reliability

Compared to other drying methods, the double-cone vacuum dryer provides a safer and more reliable option. The closed system reduces the risk of contamination, while robust construction ensures long-term durability. These factors contribute to a stable and dependable drying process.

Operating Principles

Understanding the operating principles of the double-cone vacuum dryer can help you optimize its use in the laboratory:

Loading the Material

The material to be dried is loaded into the dryer, filling it to about two-thirds of its capacity. This allows for sufficient movement and mixing during the drying process. Proper loading is critical to ensure that the material is evenly distributed, maximizing the efficiency of heat transfer and drying.

Creating a Vacuum

Once the material is loaded, a vacuum pump extracts air from the chamber, creating a low-pressure environment. This reduces the moisture’s boiling point, facilitating efficient evaporation. The vacuum level can be adjusted based on the material’s specific requirements, providing control over the drying process.

Heating and Mixing

The dryer is equipped with a heating jacket that provides indirect heat to the material. The double-cone design ensures continuous mixing, which promotes uniform drying. Mixing not only enhances heat distribution but also prevents clumping and ensures that even the most challenging materials are dried effectively.

Monitoring and Control

Modern double-cone vacuum dryers come with advanced monitoring systems that allow you to control temperature, pressure, and drying time. This ensures precise drying conditions tailored to the specific material. Real-time data can be used to make adjustments on-the-fly, optimizing the process and improving outcomes.

Process Optimization

Regular analysis of drying cycles can lead to process optimization. By understanding the interaction between different parameters, laboratories can fine-tune operations to achieve the best possible results. This continuous improvement approach helps maintain high standards and adapt to new challenges.

Maintenance and Safety Considerations

Proper maintenance and safety practices are essential for the optimal operation of a double-cone vacuum dryer:

Regular Cleaning

After each use, it’s essential to thoroughly clean the dryer to prevent contamination and ensure consistent performance. This involves disassembling parts and cleaning them with suitable solvents. Regular cleaning also helps identify wear and tear early, preventing potential breakdowns.

Safety Precautions

Safety is paramount when operating a vacuum dryer. Ensure that all safety protocols are followed, including wearing protective gear and conducting regular equipment inspections. Safety measures protect personnel and maintain a secure laboratory environment, preventing accidents and ensuring compliance with regulations.

Troubleshooting Common Issues

Common issues, such as vacuum leaks or uneven drying, can often be resolved by checking seals and gaskets, ensuring proper loading, and calibrating monitoring systems. Troubleshooting guides and manufacturer support can assist in resolving more complex problems, minimizing downtime.

Scheduled Maintenance

Implementing a scheduled maintenance plan can extend the lifespan of the equipment and ensure reliable performance. Regularly servicing the vacuum pump, inspecting electrical components, and verifying the integrity of seals contribute to the dryer’s long-term functionality.

Training and Documentation

It is crucial to provide comprehensive training for laboratory staff on the operation and maintenance of the double-cone vacuum dryer. Detailed documentation of procedures and protocols supports consistent practices and enhances overall safety and efficiency.

Conclusion

The double-cone vacuum dryer is an indispensable tool for laboratories that require precise and efficient powder drying. Its unique design and operational advantages make it suitable for a wide range of applications, from pharmaceuticals to food processing. By understanding its features and operating principles, you can leverage this equipment to enhance your laboratory’s productivity and product quality.

Incorporating a double-cone vacuum dryer into your laboratory setup can significantly improve drying efficiency and material quality. As technology advances, these dryers continue to evolve, offering even greater capabilities and benefits.

For laboratories looking to upgrade their drying processes, the double-cone vacuum dryer is a worthy investment. Its versatility, efficiency, and effectiveness make it a cornerstone of modern laboratory operations. Embracing this technology positions laboratories at the forefront of innovation, enabling them to meet today’s demands and tomorrow’s challenges.

Specifications

|

Model

|

100

|

500

|

1000

|

1500

|

2000

|

5000

|

|

Volume (L)

|

100

|

500

|

1000

|

15000

|

2000

|

5000

|

|

Maximum Loading Volume (L)

|

40

|

200

|

400

|

600

|

800

|

2000

|

|

Maximum Loading Capacity (kg)

|

20

|

100

|

200

|

300

|

400

|

1000

|

|

Rotating Speed (rpm)

|

3~13

|

6

|

5

|

4

|

||

|

Motor Power (k w)

|

0.75

|

1.5

|

3

|

4

|

5.5

|

15

|

|

Floor Area (mm)

|

2160 × 800

|

2350× 800

|

2860 × 1300

|

3060 × 1300

|

3260 × 1400

|

4400 × 2500

|

|

Rotation Height (mm)

|

1750

|

2250

|

2800

|

2940

|

2990

|

4200

|

|

Design Pressure In Container (MPa)

|

-0.09 to 0.096

|

|||||

|

Interlayer Design Pressure (MPa)

|

≤ 0.3

|

|||||

|

Weight (kg)

|

800

|

1200

|

2800

|

3300

|

3600

|

8600

|

Applications

Applicable Industries: Machinery Repair Shops, Food & Beverage Factory, Farms, Retail, Food Shop, Energy & Mining, Food & Beverage Shops