Table of Contents

Product Detail

In recent years, the demand for efficient and sustainable processing technologies has grown significantly. As industries strive to minimize environmental impact and optimize operational efficiency, innovative solutions are emerging to meet these needs. One such advancement is the vacuum blender dryer desolventization process, a technique that’s gaining traction across various industries, including biodiesel production, pharmaceuticals, and food processing. This article will delve into the workings of vacuum blender dryers, their application in desolventization, and how they enhance the biodiesel production process, among other uses.

What is a Vacuum Blender Dryer?

A vacuum blender dryer is a versatile piece of equipment designed to dry, mix, and desolventize materials. It is engineered to operate under vacuum conditions, meaning that the pressure inside the dryer is lower than the atmospheric pressure. This setup allows for the evaporation of solvents at lower temperatures, making it an energy-efficient solution for drying heat-sensitive materials. The design and functionality of vacuum blender dryers make them indispensable in industries that require gentle and effective drying processes.

Principles of Operation

The operation of a vacuum blender dryer is based on several scientific principles. Firstly, the concept of reduced pressure is crucial, as it lowers the boiling point of solvents, allowing for evaporation at lower temperatures. This principle is particularly beneficial for materials that are sensitive to heat. Additionally, the process utilizes the principles of heat transfer and mass transfer to ensure efficient drying and desolventization. By combining these principles, vacuum blender dryers are able to achieve high-quality results with minimal energy consumption.

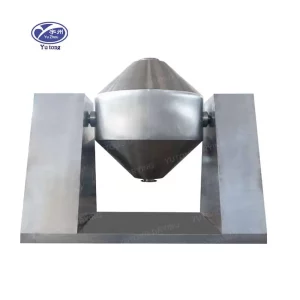

Construction and Design

The construction of a vacuum blender dryer involves several key components, each contributing to its functionality. The main chamber is designed to withstand vacuum conditions and is typically constructed from materials that are resistant to corrosion and high temperatures. Inside the chamber, a blending mechanism ensures thorough mixing of the material, promoting uniform heat distribution. The dryer is also equipped with a heating system to facilitate heat transfer and an efficient vacuum system to maintain the necessary pressure conditions.

Safety and Maintenance

Safety is a paramount consideration in the design of vacuum blender dryers. The equipment is equipped with safety features such as pressure relief valves and temperature controls to prevent accidents. Regular maintenance is essential to ensure the dryer’s longevity and efficiency. This includes routine inspections of the vacuum system, cleaning of the mixing blades, and checking for any signs of wear and tear. Proper maintenance not only enhances the dryer’s performance but also ensures safe operation.

Applications in Biodiesel Production

Biodiesel production involves converting fats or oils into fatty acid methyl esters (FAME) through a process called transesterification. This chemical reaction produces by-products like glycerol, which requires further processing to ensure its purity and usability. Vacuum blender dryers play a crucial role in this industry by enhancing the efficiency and sustainability of the production process.

Role in Transesterification

During transesterification, the separation of glycerol from biodiesel is a critical step. The presence of residual solvents in glycerol can affect its quality and usability. Vacuum blender dryers facilitate the gentle removal of these solvents, ensuring that the glycerol is of high purity. The ability to operate at lower temperatures minimizes the risk of degrading the glycerol, making the process both efficient and environmentally friendly.

Vacuum Dryer for Glycerol

Glycerol, a by-product of biodiesel production, contains impurities and residual solvents that must be removed before it can be utilized or sold. A vacuum dryer for glycerol is particularly effective because it allows for the gentle removal of solvents without degrading the glycerol. By using a vacuum blender dryer, producers can achieve high-purity glycerol with minimal energy consumption. The vacuum conditions facilitate the removal of solvents at lower temperatures, preserving the quality of the glycerol and making the process environmentally friendly.

Enhancing Biodiesel Quality

The purity of its components heavily influences the quality of the final biodiesel product. Vacuum blender dryers contribute to the production of high-quality biodiesel by ensuring that impurities and solvents are effectively removed. This not only enhances the performance of the biodiesel but also its compliance with industry standards and regulations. As a result, biodiesel producers can deliver a superior product to the market, meeting the growing demand for cleaner and more sustainable fuels.

Advantages of Vacuum Blender Dryer Desolventization

The vacuum blender dryer desolventization process offers several benefits, particularly in the context of biodiesel production and other industries where solvent removal is critical. These advantages underscore the importance of this technology in modern industrial processes.

Energy Efficiency

One key advantage of using a vacuum blender dryer is its energy efficiency. Traditional drying methods often require high temperatures to evaporate solvents, leading to significant energy consumption. However, by operating under vacuum conditions, the vacuum blender dryer allows for solvent evaporation at lower temperatures, reducing energy usage and costs. This energy efficiency translates into lower operational expenses and a reduced carbon footprint, making it an attractive option for environmentally conscious industries.

Preservation of Material Quality

The ability to dry and desolventize materials at lower temperatures is especially beneficial for heat-sensitive substances. By preventing exposure to high temperatures, the vacuum blender dryer helps maintain the integrity and quality of the material, ensuring that the end product meets the desired specifications. This preservation of material quality is critical in industries such as pharmaceuticals and food processing, where the efficacy and safety of the products are paramount.

Environmental Impact

Reducing energy consumption not only cuts costs but also minimizes the drying process’s environmental impact. The vacuum blender dryer’s ability to operate efficiently at lower temperatures means fewer greenhouse gas emissions, contributing to a more sustainable production process. This reduction in environmental impact aligns with global efforts to combat climate change and promotes a more responsible approach to industrial operations.

Key Features of Vacuum Blender Dryers

Several features make vacuum blender dryers a preferred choice for desolventization and drying processes. These features enhance the equipment’s versatility, efficiency, and functionality, making it suitable for a wide range of applications.

Versatile Design

Vacuum blender dryers are designed to handle a wide range of materials, from powders to pastes. Their versatility makes them suitable for various industries, including pharmaceuticals, chemicals, and food processing. The ability to accommodate different types of materials ensures that vacuum blender dryers can meet the diverse needs of various industries, making them a flexible and adaptable solution.

Efficient Mixing

The integrated mixing mechanism ensures uniform heat distribution and promotes efficient solvent removal. This feature is crucial for achieving consistent product quality and optimizing the desolventization process. Efficient mixing not only enhances the dryer’s performance but also reduces processing time, leading to increased productivity and cost savings.

Customizable Options

Manufacturers often offer customizable options for vacuum blender dryers, allowing users to tailor the equipment to their specific needs. From capacity and material compatibility to automation and control systems, these customizable features enhance the equipment’s versatility and functionality. Customization ensures that the dryer meets the unique requirements of each application, maximizing its effectiveness and efficiency.

Real-World Applications

Vacuum blender dryers’ applications extend beyond biodiesel production, with several industries benefiting from this technology. Their versatility and efficiency make them valuable assets in diverse industrial settings.

Pharmaceutical Industry

In the pharmaceutical industry, vacuum blender dryers are used to dry active pharmaceutical ingredients (APIs) and remove solvents from drug formulations. Their ability to preserve the quality of heat-sensitive compounds makes them invaluable in producing high-quality pharmaceuticals. By ensuring the purity and efficacy of pharmaceutical products, vacuum blender dryers play a critical role in safeguarding public health and meeting stringent regulatory standards.

Food Processing

In food processing, vacuum blender dryers are employed to dry and desolventize flavorings, extracts, and other ingredients. The gentle drying process helps retain the flavor and nutritional value of the ingredients while ensuring their stability and shelf life. This preservation of quality is essential for delivering safe and delicious food products to consumers and maintaining the competitiveness of food processing companies.

Chemical Industry

The chemical industry also benefits from the use of vacuum blender dryers, particularly in processes that involve the removal of solvents from chemical compounds. The ability to operate at lower temperatures reduces the risk of chemical degradation, ensuring that the final product meets the required specifications. This capability is essential for producing high-quality chemical products that meet the needs of various industrial applications.

Conclusion

The vacuum blender dryer desolventization process is an innovative and efficient solution for removing solvents from various materials. Its application in biodiesel production, particularly for processing glycerol, highlights its potential to enhance sustainability and efficiency in industrial processes. By leveraging the benefits of vacuum conditions, energy efficiency, and material preservation, vacuum blender dryers are poised to become a staple in industries where solvent removal is critical.

As demand for cleaner and more sustainable production methods grows, this technology will undoubtedly play a pivotal role in shaping the future of industrial processing. Whether you’re in the biodiesel sector, pharmaceuticals, or food processing, integrating vacuum blender dryers into your operations could be the key to unlocking greater efficiency and sustainability. Embracing this technology not only enhances operational performance but also contributes to a more sustainable and environmentally responsible future.

Specifications

No Content Matching Your Selection Is Found.

Applications

No Content Matching Your Selection Is Found.