Table of Contents

Product Detail

Basic principle

Three-dimensional motion mixer in running, running action, because the mixing barrel has multiple directions to make all kinds of material in the process of mixing, speeding up the flow and diffusion effect, at the same time avoid the general mixing machine because of centrifugal force effect produced by the specific gravity segregation and accumulation phenomenon, no dead Angle, can effectively ensure the mixed material of better quality.

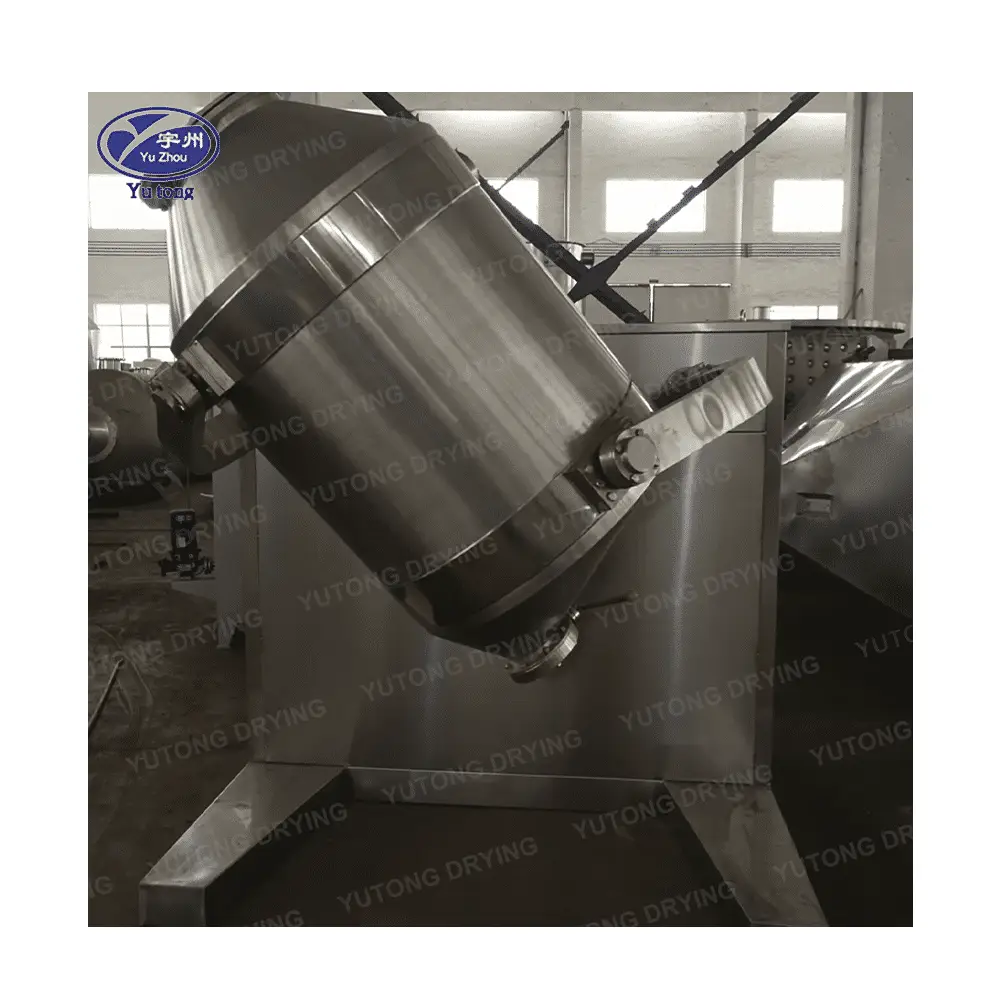

Product Descriptions

The machine is widely used in chemical, food, metallurgy, light industry, and scientific research units. It can mix the powder or granular materials with good fluidity very evenly so that the mixed materials can reach the best mixing state.

During the operation of this machine, because the mixing barrel body has a multi-direction operation, the flow and diffusion of all kinds of materials in the mixing process are accelerated, and the phenomenon of material gravity segregation and accumulation caused by centrifugal force in the general mixer is avoided. The mixing has no dead Angle and can effectively ensure the good quality of mixed materials. Structure: the machine is composed of a frame, transmission system, electrical control system, multi-direction motion mechanism, mixing barrel, and other components. The mixing barrel which is in direct contact with the material is made of stainless steel, and the inner and outer walls of the barrel are polished. Fully comply with GMP requirements.

Principle:

Three-dimensional motion mixer in running, running action, because the mixing barrel has multiple directions to make all kinds of material in the process of mixing, speeding up the flow and diffusion effect, at the same time avoid the general mixing machine because of centrifugal force effect produced by the specific gravity segregation and accumulation phenomenon, no dead Angle, can effectively ensure the mix material of better quality.

Main Features

1) The material has no centrifugal effect, incomparable segregation, stratification, or accumulation phenomenon each component can have a great difference in weight ratio and, mixing rate of more than 99.9% so that the current various mixer in a relative product.

2)Large loading rate, up to 80%, high efficiency, short mixing time.

3) Simplified everywhere for arc transition, and after precision polishing treatment, to meet the GMP requirements

Structure:

The three-dimensional moving mixer is composed of frame, transmission system, electrical control system,multi-direction moving working mechanism, mixing barrel and other parts. The mixing barrel which is in direct contact with the material is made of stainless steel, and the inner and outer walls of the barrel are polished.

Specifications

|

Type

|

SYH-5

|

SYH-100

|

SYH-200

|

SYH-400

|

SYH-600

|

SYH-800

|

SYH-1000

|

|

Material barrel volume (L)

|

5

|

100

|

200

|

400

|

600

|

800

|

1000

|

|

Max loading volume (L)

|

4.25

|

85

|

170

|

340

|

510

|

680

|

850

|

|

Max loading weight (kg)

|

5

|

80

|

150

|

200

|

300

|

400

|

500

|

|

Spindle rotation speed (r/min)

|

24

|

15

|

12

|

10

|

10

|

10

|

10

|

|

Motor power (kw)

|

0.37

|

2.2

|

3

|

4

|

5.5

|

7.5

|

11

|

|

Overall dimensions (mm)

|

600 x 1000 x1000

|

1200×1800 x1500

|

1300x1600x1500

|

1500x2200x1500

|

1850x2500x1650

|

1900x2400x2100

|

1950x2500x2400

|

|

Weight (kg)

|

150

|

500

|

750

|

1200

|

1500

|

1650

|

1800

|

Applications

No Content Matching Your Selection Is Found.