Table of Contents

Product Detail

Spray drying is a transformative process that has significantly impacted various industries by offering a rapid and efficient method to convert liquid materials into dry powder form. This technique is invaluable across sectors such as food, pharmaceuticals, and chemicals. Understanding the cost dynamics of spray dryer machines in India is crucial for businesses aiming to budget and plan effectively. This article delves into the factors influencing spray dryer machine prices and highlights prominent manufacturers in key Indian industrial hubs like Ahmedabad, Pune, and Gujarat.

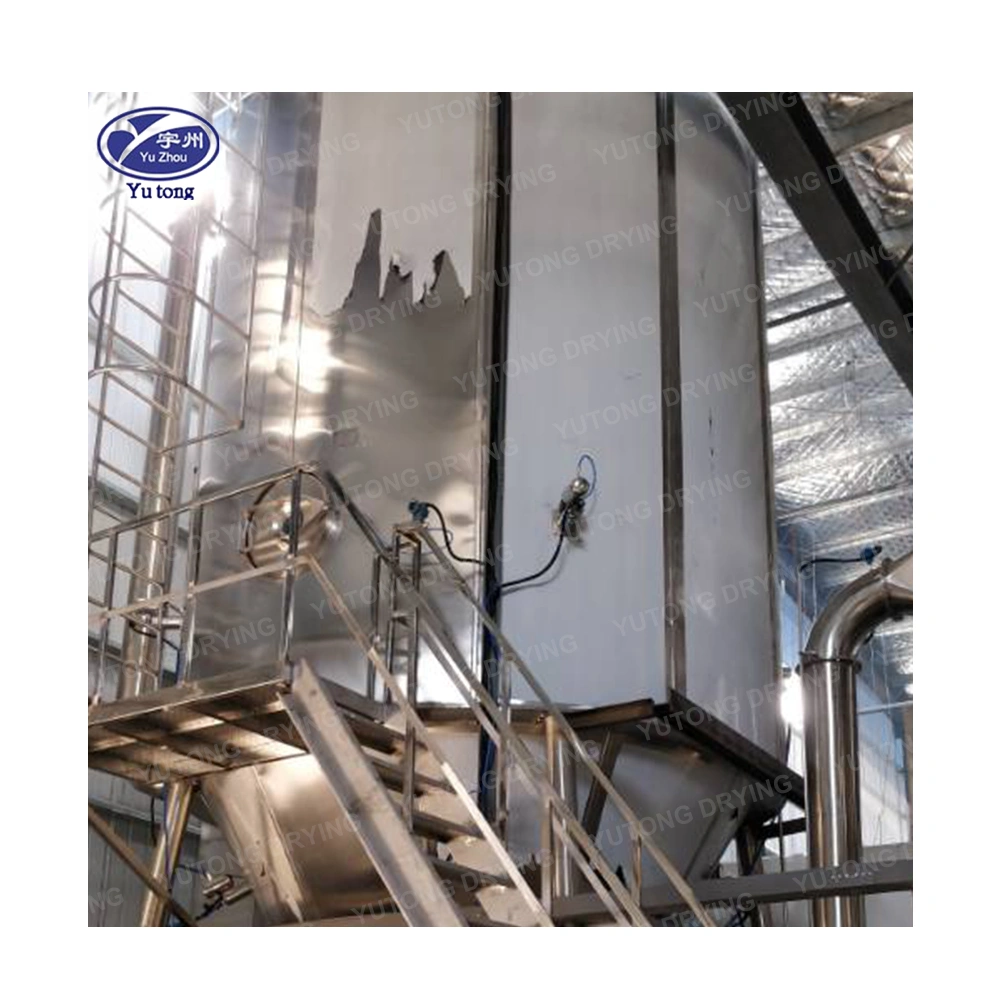

Understanding Spray Drying Equipment

Spray drying equipment is engineered to handle a wide range of materials, transforming liquids into powders through rapid drying using hot gas. This process is especially beneficial for heat-sensitive products, ensuring product integrity while achieving desired dryness levels.

Key Components of Spray Drying Machines

Spray drying machines consist of several critical components, each playing a vital role in the drying process. Understanding these components is crucial for comprehending how they influence the machine’s price.

- Atomizer: This essential component disperses the liquid into fine droplets, facilitating efficient drying. Different types of atomizers, such as rotary and nozzle atomizers, can impact both performance and cost.

- Drying Chamber: The drying chamber is where the actual drying occurs, as hot air is introduced to evaporate moisture from the droplets. The size and design of the chamber can vary, affecting the machine’s capacity and efficiency.

- Collector: This part collects the dried powder after moisture removal. The design and material of the collector can influence the final product quality and the overall price of the machine.

Additional Features and Customization

Beyond the essential components, many spray drying machines offer additional features that enhance functionality and increase cost. Customization options allow businesses to tailor machines to their specific needs, impacting the overall price.

- Heat Exchangers: These components improve energy efficiency by preheating incoming air, reducing operational costs over time. The inclusion of heat exchangers can raise the initial investment but offer long-term savings.

- Control Panels: Advanced control systems provide precise management of the drying process, ensuring consistent product quality. The complexity and sophistication of these systems can significantly affect pricing.

- Cleaning Systems: Automated cleaning systems enhance convenience and hygiene, which is particularly important in food and pharmaceutical applications. These systems can add to the machine’s cost but improve operational efficiency.

Factors Influencing Spray Dryer Machine Prices in India

Several factors contribute to the cost of spray drying machines in India. Understanding these factors helps businesses make informed purchasing decisions.

Capacity and Size

The capacity and size of spray drying machines are primary determinants of their price. Larger machines with higher capacities naturally cost more due to the increased materials used and the complexity of the equipment.

- Production Needs Assessment: Businesses must assess their production requirements to select the appropriate machine size. Overestimating or underestimating capacity can lead to inefficiencies and increased costs.

- Space Considerations: The physical space available for installation can influence the choice of machine size. Larger machines require more space, impacting both cost and logistical considerations.

- Scalability: Some businesses anticipate growth and opt for machines with scalable capacities. While this can increase initial costs, it offers flexibility for future expansion.

Material of Construction

The materials used in constructing spray dryers affect both durability and cost. Stainless steel is a common choice for its resistance to corrosion, especially in food and pharmaceutical applications.

- Material Selection: The choice of construction material impacts the machine’s longevity and maintenance costs. High-quality materials may increase initial expenses but reduce long-term repair needs.

- Industry Standards: Certain industries have specific material requirements for compliance with safety and hygiene standards. Meeting these standards can affect the machine’s price.

- Environmental Considerations: Some materials offer better ecological sustainability, appealing to businesses focused on eco-friendly practices. These considerations can influence both material choice and cost.

Automation and Control Systems

Advanced machines with sophisticated automation and control systems are pricier but offer precise control over the drying process, leading to better product consistency.

- Technological Advancements: The integration of cutting-edge technology can enhance process efficiency and product quality, justifying higher costs.

- Ease of Use: User-friendly interfaces and automation reduce the need for extensive training, potentially lowering operational expenses in the long run.

- Customization Options: Businesses can often select specific control features tailored to their process requirements, influencing the machine’s overall price.

Energy Efficiency

Energy-efficient models may have a higher upfront cost but can save money in the long run through reduced energy consumption.

- Cost-Benefit Analysis: Assessing the long-term savings from energy-efficient models helps justify higher initial investments.

- Environmental Impact: Energy-efficient machines align with sustainability goals, appealing to environmentally conscious businesses.

- Government Incentives: Some regions offer incentives or tax benefits for investing in energy-efficient equipment, potentially offsetting higher upfront costs.

Price Range of Spray Dryer Machines in India

The price of spray dryer machines in India can vary widely based on several factors. On average, businesses can expect the following price ranges:

- Small-scale Units: Starting from ₹5 lakh to ₹15 lakh, these units cater to more minor production needs and are ideal for startups or businesses with limited space.

- Medium-scale Units: Priced between ₹15 lakh to ₹50 lakh, these machines offer higher capacities and more features, suitable for growing businesses.

- Large-scale Units: Can exceed ₹50 lakh, depending on customization and capacity. These units are designed for high-volume production and advanced process requirements.

Comparing Quotes and Ensuring Value

- Supplier Comparison: It’s crucial to compare quotes from different manufacturers to ensure you get the best deal that fits your budget and requirements.

- Understanding Inclusions: Clarify what is included in the quoted price, such as installation, training, and after-sales support, to avoid unexpected costs.

- Negotiation Opportunities: Engage in negotiations with suppliers to explore potential discounts or added-value services.

Notable Spray Dryer Manufacturers in India

India hosts several reputable manufacturers known for producing high-quality spray drying equipment. These manufacturers are spread across key industrial regions and offer diverse product options.

Spray Dryer Manufacturers in Ahmedabad

Ahmedabad is a hub for industrial equipment manufacturing, including spray dryers. Companies here are known for their robust design and competitive pricing.

- Shachi Engineering: Renowned for custom solutions tailored to specific industry needs, Shachi Engineering offers versatile and reliable spray dryers.

- Technology System Engineering Pvt. Ltd.: This company provides a range of spray dryers with varying capacities and features, focusing on quality and innovation.

- Customer-Centric Approach: Manufacturers in Ahmedabad often emphasize customer satisfaction, offering personalized services and support.

Spray Dryer Manufacturers in Pune

Pune is another significant location for spray dryer manufacturing, offering innovative solutions and reliable equipment.

- Acmefil Engineering Systems Pvt. Ltd.: Known for its state-of-the-art technology and customer-centric approach, Acmefil Engineering delivers efficient and durable machines.

- SVAAR Process Solutions: This company offers energy-efficient models with modern control systems, meeting diverse industry needs.

- Focus on Innovation: Pune-based manufacturers prioritize innovation, ensuring their equipment stays ahead of industry trends.

Spray Dryer Manufacturers in Gujarat

Gujarat, being an industrial powerhouse, hosts numerous manufacturers focusing on quality and innovation.

- Vijay Engineering: Provides a wide range of dryers catering to different industries, known for their robust construction and efficiency.

- Raj Dryers: Known for their durable and efficient drying solutions, Raj Dryers emphasizes quality and performance.

- Commitment to Excellence: Manufacturers in Gujarat are dedicated to maintaining high standards, ensuring customer satisfaction and reliability.

Choosing the Right Manufacturer

Selecting the proper spray dryer manufacturer in India involves careful consideration of several factors. Here are some key aspects to evaluate:

Reputation and Experience

- Proven Track Record: Look for companies with a history of success and satisfied customers in the industry.

- Industry Expertise: Manufacturers with extensive experience understand industry-specific needs and challenges, offering tailored solutions.

- Customer Reviews and Testimonials: Research customer feedback and testimonials to gauge the manufacturer’s reliability and service quality.

Customization Options

- Tailored Solutions: Ensure the manufacturer can customize equipment to meet your specific process requirements and production goals.

- Flexibility in Design: Manufacturers offering flexible design options can accommodate unique business needs, enhancing operational efficiency.

- Collaboration and Consultation: A collaborative approach during the customization process ensures the final product aligns with your expectations.

After-Sales Support

- Maintenance and Repairs: Reliable after-sales support includes maintenance and repair services, ensuring equipment longevity and performance.

- Training and Assistance: Manufacturers providing training and technical assistance help optimize equipment use and minimize downtime.

- Availability of Spare Parts: Ensure the manufacturer offers readily available spare parts, reducing potential delays in case of equipment issues.

Conclusion

Investing in a spray dryer machine is a significant decision that requires careful consideration of various factors, including capacity, material, and manufacturer reputation. By understanding the elements that influence price and knowing where to find reputable manufacturers in India, businesses can make informed decisions that align with their operational goals and budget constraints.

The information provided here serves as a guide to navigating the complexities of purchasing spray drying equipment in India, ensuring a well-informed and strategic investment. Whether you are in Ahmedabad, Pune, or Gujarat, the right spray dryer can enhance productivity and quality in your production processes. Taking the time to research and evaluate options ensures that businesses invest in equipment that meets their specific needs and drives growth.

Specifications

|

spec

|

ZPG-25

|

ZPG-50

|

ZPG-80

|

ZPG-100

|

ZPG-150

|

ZPG-200

|

ZPG-300

|

|

|

evaporation capacity(kg/h)

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

|

process amount of material liquid(kg/h)

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

|

output of finished pcoduct(kg/h)

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

24-42

|

36.8-56.4

|

55-85

|

|

|

solid content of material liquid( %)

|

18-30

|

|||||||

|

moisture content of finished product( %)

|

3-5

|

|||||||

|

electric power(kw)

|

63

|

132

|

153

|

204

|

246

|

330

|

||

|

heat source

|

Steam pius electricity

|

|||||||

|

Collecting method of product and its efficiency

|

Grade one or two or three stage cyclone wet dust remover is greater than or equal to 95%

|

|||||||

|

automatic control meters and instruments

|

indicator of not air and exhaust air temperature

|

|||||||

|

temperature of air inlet(℃)

|

160-220

|

|||||||

|

temperature of air outlet(℃)

|

80-100

|

|||||||

|

L

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15000

|

|

|

overal dimensions(mm)

|

W

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

H

|

6200

|

6900

|

8000

|

8900

|

10750

|

11900

|

13000

|

|

Applications

Applicable Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Retail, Food & Beverage Shops