Table of Contents

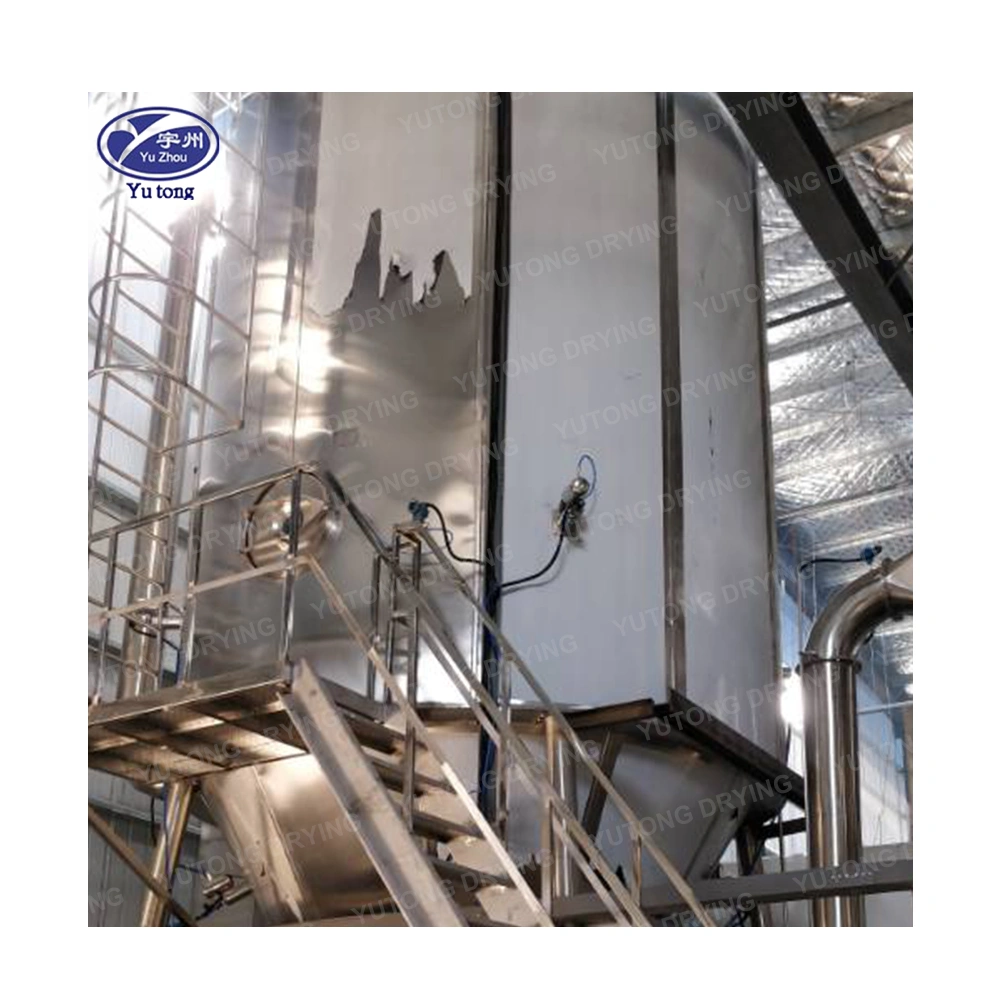

Product Detail

Spray drying is a pivotal process in the food industry, transforming liquids into dry powders. This conversion not only makes handling easier but also significantly extends the shelf life of food products. From milk and infant formula to nutraceuticals, spray dryers are indispensable for food preservation and processing. This article explores the mechanics, benefits, and various types of spray dryers, emphasizing their essential role in the food industry today.

What is a Spray Dryer?

Spray dryers are sophisticated devices designed to produce dry powder from a liquid by rapidly drying it with hot gas. This method is particularly suitable for heat-sensitive materials, making it ideal for food products like milk powder and infant formula.

The Process of Atomization

Atomization is the first critical step in spray drying. The liquid solution or slurry is atomized into tiny droplets using nozzles or rotary atomizers. This step is crucial as it determines the surface area exposed to the drying air, directly impacting the drying rate and final particle size.

Hot Air Drying Mechanism

Once the liquid is atomized, the fine droplets are introduced into a stream of hot air within a drying chamber. The high temperature causes rapid evaporation of moisture from the droplets, leaving behind dry powder particles. This fast drying is essential for preserving the quality and nutritional value of the food product.

Collection and Separation

After drying, the powder particles are separated from the drying air using cyclones or bag filters. This separation process ensures that the final product is free from any airborne contaminants and ready for packaging. The efficiency of this step is vital for maintaining product purity and quality.

Importance of Spray Dryers in the Food Industry

Spray dryers are critical in the food industry for numerous reasons, each contributing to the overall efficiency and quality of food processing.

Enhanced Preservation and Extended Shelf Life

Converting liquids into powders removes moisture, a primary factor in microbial growth, thus significantly extending the shelf life of food products. This preservation technique is crucial for maintaining product quality during long-term storage.

Improved Handling and Storage

Dry powders are considerably easier to handle and store compared to liquid forms. This ease of handling is particularly beneficial for global distribution, where transportation and storage conditions can vary widely.

Cost Efficiency in Production

Reducing the bulk of liquids into powders decreases transportation costs and minimizes storage requirements. This cost efficiency is a significant advantage for food manufacturers aiming to optimize their supply chain logistics.

Consistent Product Quality

Spray drying provides uniform particle size and consistent quality, both of which are crucial for consumer satisfaction. Consistency in product quality is a vital aspect of brand reliability and consumer trust.

Types of Spray Dryers

There are various types of spray dryers, each designed for specific applications within the food industry.

Tetra Pak Spray Dryer

The Tetra Pak Spray Dryer is renowned for its efficiency in producing high-quality milk powders and other dairy products. It ensures uniform drying, which is essential for maintaining the nutritional value and taste of food products.

Efficiency in Dairy Production

Tetra Pak’s technology focuses on optimizing the drying process to achieve the highest efficiency in dairy production. This efficiency helps in preserving the delicate balance of nutrients and flavors in dairy products.

High-Quality Output

The output quality of Tetra Pak spray dryers is consistently high, ensuring that the end product meets stringent industry standards. This reliability is crucial for manufacturers who prioritize quality in their production processes.

Alfa Laval Spray Dryer

Alfa Laval offers a versatile range of spray dryers tailored for various needs, including the processing of milk and infant formula. These dryers are celebrated for their energy efficiency and ability to produce superior-quality powders.

Versatility in Applications

Alfa Laval spray dryers are designed to handle a wide range of applications, making them suitable for diverse food processing needs. This versatility allows manufacturers to adapt to changing market demands efficiently.

Focus on Energy Efficiency

Energy efficiency is a hallmark of Alfa Laval’s spray dryers, achieved through advanced heat exchange systems. This focus on reducing energy consumption is not only environmentally friendly but also cost-effective for manufacturers.

Pulse Combustion Spray Dryer

Pulse combustion spray dryers utilize pulsating hot air to dry droplets, offering greater efficiency and finer particle sizes. This method is suitable for applications where particle size and energy efficiency are critical.

Advanced Drying Technology

The advanced technology in pulse combustion dryers allows for precise control over the drying process, resulting in uniform particle sizes. This precision is essential for applications requiring specific particle characteristics.

Energy-Saving Benefits

The pulsating air technique used in these dryers reduces energy consumption while maintaining high drying efficiency. This energy-saving benefit is significant for manufacturers looking to reduce operational costs.

Nutraceutical Spray Dryer

Specialized spray dryers for nutraceuticals focus on maintaining the bioavailability of nutrients, which is crucial for their efficacy. They are designed to handle the delicate nature of nutraceutical ingredients with care.

Preserving Nutrient Integrity

Nutraceutical spray dryers are engineered to preserve the bioactive compounds in the products, ensuring that they remain effective. This preservation is vital for maintaining the health benefits that nutraceuticals offer.

Handling Delicate Ingredients

The design of these dryers takes into account the fragile nature of nutraceutical ingredients, providing gentle drying conditions that prevent degradation. This careful handling is essential for maintaining product integrity.

How Does a Spray Dryer Work?

The spray drying process involves several key steps, each contributing to the efficient conversion of liquid into powder.

Atomization Techniques

Atomization is achieved using nozzles or rotary atomizers to create fine droplets from the liquid. The choice of atomization technique depends on the specific requirements of the product being processed, such as desired particle size and distribution.

Efficient Drying Process

Once atomized, the droplets enter a stream of hot air, where the rapid evaporation of moisture occurs. This drying process is carefully controlled to ensure that the final powder retains its intended properties and quality.

Effective Separation Methods

After drying, the powder is separated from the drying air using advanced filtration methods like cyclones or bag filters. These methods are essential for ensuring that the final product is free from contaminants and meets quality standards.

Final Collection and Packaging

The dried powder is then collected and packaged for distribution. Proper packaging is crucial to protect the powder from environmental factors such as moisture and light, which can affect its quality during storage.

Energy Efficiency and Consumption

Energy consumption is a critical consideration in operating spray dryers, and modern designs focus on maximizing efficiency.

Innovations in Energy Use

Modern spray dryers, such as those from Alfa Laval and Tetra Pak, incorporate advanced heat exchange systems to minimize energy use. These innovations help reduce the spray drying process’s overall energy footprint.

Waste Heat Recovery Systems

Implementing waste heat recovery systems is a significant advancement in improving energy efficiency. By capturing and reusing waste heat, manufacturers can significantly reduce energy costs and environmental impact.

Advances in Atomization Technology

Ongoing innovations in atomization technology aim to enhance energy efficiency further. These advances focus on optimizing the size and distribution of droplets, which can lead to more efficient drying and reduced energy consumption.

Applications in the Food Industry

Spray dryers have a diverse range of applications in the food industry, each contributing to the versatility and efficiency of food processing.

Milk and Dairy Product Processing

Spray dryers convert liquid milk into milk powder, a staple ingredient in various food products. Compared to fluid milk, milk powder is more convenient in terms of storage and transportation.

Role in the Dairy Industry

The dairy industry relies heavily on spray drying to produce milk powder, which is used globally in products ranging from baked goods to beverages. This reliance underscores the importance of spray drying in the dairy sector.

Benefits of Milk Powder

Milk powder offers numerous benefits, including extended shelf life, reduced transportation costs, and consistent quality. These advantages make it a preferred choice for manufacturers and consumers alike.

Production of Infant Formula

High-quality spray dryers are essential for preserving the nutrients in infant formula powders, which are crucial for infant health. The ability to maintain nutritional integrity is vital for ensuring the well-being of infants.

Nutrient Preservation

Spray drying ensures that the essential nutrients in infant formula are preserved during processing. This preservation is critical for providing infants with the necessary nutrients for healthy growth and development.

Importance for Infant Health

The quality of infant formula is directly linked to infant health, making the role of spray dryers in maintaining product quality indispensable. Manufacturers prioritize using advanced spray drying technology to meet stringent health standards.

Nutraceuticals and Bioactive Compounds

Spray dryers play a key role in preserving the bioactive compounds in nutraceuticals, ensuring they remain effective. This preservation is crucial for maintaining the health benefits that nutraceutical products promise.

Maintaining Bioavailability

The bioavailability of nutrients in nutraceuticals is a primary concern during processing. Spray drying helps in maintaining this bioavailability, ensuring that consumers receive the intended health benefits.

Expanding Nutraceutical Market

As the demand for nutraceuticals grows, the role of spray dryers in producing high-quality products becomes increasingly important. The industry relies on advanced spray drying techniques to meet consumer expectations.

Flavor and Colorant Encapsulation

Spray drying encapsulates flavors and colorants, protecting them from degradation and making them easy to incorporate into food products. This encapsulation is essential for maintaining product quality and consumer appeal.

Protection from Degradation

Encapsulation protects flavors and colorants from environmental factors that can cause degradation, such as heat and light. This protection ensures that the sensory qualities of food products remain intact during storage and use.

Enhancing Product Appeal

The ability to easily incorporate encapsulated flavors and colorants into food products enhances their appeal to consumers. This enhancement is a key factor in product differentiation and market success.

Challenges and Considerations

While spray dryers offer numerous benefits, there are several challenges and considerations that manufacturers must address.

High Initial Cost

Spray dryers can be expensive to purchase and install, posing a significant investment for manufacturers with significantly smaller operations. This initial cost is a crucial factor in the decision-making process for adopting spray drying technology.

Investment Considerations

Manufacturers must weigh the long-term benefits of spray drying against the initial investment costs. Careful consideration of return on investment and potential cost savings is essential for making informed decisions.

Financial Planning

Effective financial planning is necessary to manage the costs associated with purchasing and installing spray dryers. This planning includes budgeting for ongoing operational and maintenance expenses.

Technical Expertise Requirements

Operating spray dryers requires technical knowledge to ensure optimal performance and product quality. This expertise is crucial for maintaining efficiency and preventing operational issues.

Importance of Skilled Operators

Skilled operators are essential for the successful operation of spray dryers. They have the expertise to manage complex processes and troubleshoot issues. Investing in training and development is vital for maintaining a skilled workforce.

Training and Development

Manufacturers must prioritize training programs to equip operators with the necessary skills and knowledge. Continuous education and development are key to keeping up with technological advancements in spray drying.

Maintenance and Downtime

Regular maintenance is necessary to prevent downtime and ensure the longevity of spray drying equipment. Proper maintenance practices are essential for maximizing efficiency and minimizing operational disruptions.

Preventive Maintenance Strategies

Implementing preventive maintenance strategies helps in identifying potential issues before they lead to significant downtime. Regular inspections and routine servicing are crucial components of effective maintenance programs.

Ensuring Equipment Longevity

Proper maintenance practices not only prevent downtime but also extend the lifespan of spray-drying equipment. Manufacturers must prioritize maintenance to protect their investment and ensure long-term operational success.

Future of Spray Drying in the Food Industry

The future of spray drying is promising, with ongoing research focused on improving efficiency and reducing costs. Innovations in technology and process optimization are driving the evolution of spray drying in the food industry.

Advancements in Technology

Technological advancements, including improvements in heat exchange systems, atomization technology, and process control, are paving the way for more efficient and cost-effective spray drying processes.

Impact on Industry Standards

As technology evolves, industry standards for spray drying are also advancing. Manufacturers must stay informed about the latest developments to remain competitive and meet changing consumer expectations.

Role of Research and Development

Research and development play a crucial role in driving innovation in spray drying technology. Ongoing research efforts aim to enhance efficiency, reduce costs, and expand the applications of spray drying in the food industry.

Training and Educational Tools

Innovations such as spray dryer animations and videos are being used for training purposes, helping operators understand the process better. These educational tools are essential for enhancing operator skills and improving process efficiency.

Benefits of Visual Learning

Visual learning tools, such as animations and videos, help users clearly understand complex processes. These tools are valuable for training operators and improving their ability to manage spray drying operations effectively.

Enhancing Operator Competence

Educational tools enhance operator competence, improving process efficiency and product quality. Investing in training and development is essential for maintaining a skilled and knowledgeable workforce.

Emerging Applications and Opportunities

Advancements in genomics and food science may lead to new applications for spray drying technology, which could expand the technology’s role in the food industry.

Exploring New Markets

Advancements in food science and consumer demand drive the exploration of new markets and applications for spray drying technology. Manufacturers must stay attuned to these trends to capitalize on emerging opportunities.

Potential for Innovation

The potential for innovation in spray drying is vast, with ongoing research uncovering new possibilities for the technology. To stay ahead in a competitive market, manufacturers must remain open to new ideas and approaches.

Conclusion

Spray dryers are a cornerstone of the modern food industry, offering a practical solution for converting liquid ingredients into stable, easy-to-handle powders. With their ability to preserve quality, extend shelf life, and improve the efficiency of food processing, spray dryers will continue to play a vital role in the industry. As technology advances, we can expect even more innovative uses and improvements in energy efficiency, making spray drying an even more valuable tool for food manufacturers. The future of spray drying is bright, with ongoing research and development promising to unlock new possibilities and applications for this essential technology.

Specifications

|

spec

|

ZPG-25

|

ZPG-50

|

ZPG-80

|

ZPG-100

|

ZPG-150

|

ZPG-200

|

ZPG-300

|

|

|

evaporation capacity(kg/h)

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

|

process amount of material liquid(kg/h)

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

|

output of finished pcoduct(kg/h)

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

24-42

|

36.8-56.4

|

55-85

|

|

|

solid content of material liquid( %)

|

18-30

|

|||||||

|

moisture content of finished product( %)

|

3-5

|

|||||||

|

electric power(kw)

|

63

|

132

|

153

|

204

|

246

|

330

|

||

|

heat source

|

Steam pius electricity

|

|||||||

|

Collecting method of product and its efficiency

|

Grade one or two or three stage cyclone wet dust remover is greater than or equal to 95%

|

|||||||

|

automatic control meters and instruments

|

indicator of not air and exhaust air temperature

|

|||||||

|

temperature of air inlet(℃)

|

160-220

|

|||||||

|

temperature of air outlet(℃)

|

80-100

|

|||||||

|

L

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15000

|

|

|

overal dimensions(mm)

|

W

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

H

|

6200

|

6900

|

8000

|

8900

|

10750

|

11900

|

13000

|

|

Applications

Applicable Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Retail, Food & Beverage Shops