Table of Contents

Product Detail

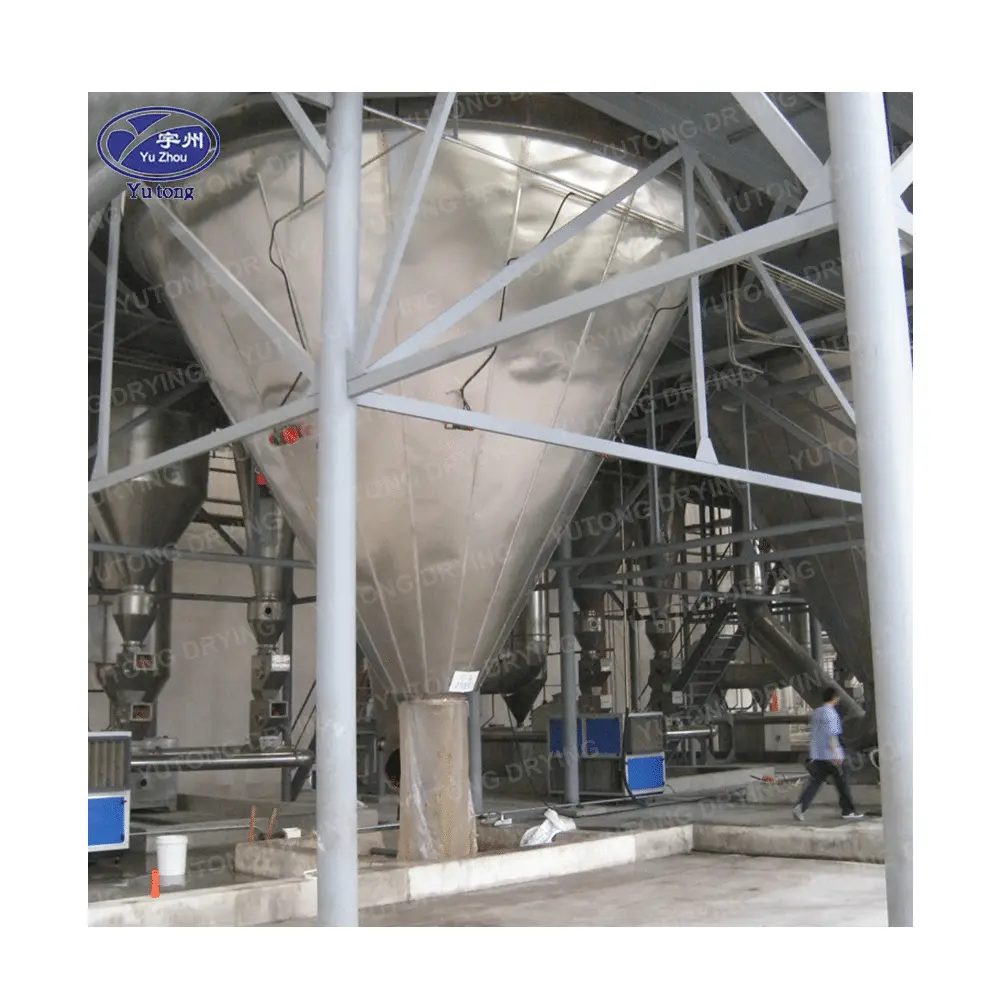

ZPG Series Spray Dryer for Diverse Industrial Applications

Benefits:

Energy-efficient Operation: The combination of steam and electricity as heating sources allows for optimized energy consumption. Steam provides bulk heating, while electricity can fine-tune temperature control, reducing overall energy bills during the drying process.

Reliable and Long-lasting: With a core motor and a build using corrosion-resistant SS304/SS316L stainless steel, the dryer is designed to withstand the rigours of continuous industrial use. This durability translates to fewer breakdowns and maintenance requirements, minimizing production downtime.

Flexible Voltage Compatibility: Operating on both 220v and 380v, it can be easily integrated into various factory settings, whether in small-scale workshops or large manufacturing plants.

Peace of Mind Warranty: The 18-month warranty offers assurance to customers. In case of any manufacturing defects or early performance issues, they can rely on professional support to get the equipment up and running smoothly.

Uses:

Food Processing: In the food industry, it’s a game-changer. It can convert liquid food ingredients like fruit purees, dairy products, and flavour extracts into dry powders. This not only extends shelf life but also enables convenient packaging and transportation. For instance, it can turn fresh juice into powdered form, ready to be reconstituted later, preserving the taste and nutrients.

Chemicals Processing: For chemical manufacturers, it’s used to dry chemical slurries, solutions, and suspensions. By precisely drying substances, it helps achieve consistent chemical formulations, which is vital for the production of pharmaceuticals, pigments, and speciality chemicals.

Plastics Processing: Plastics play a crucial role in drying resins and additives. Moisture in plastics can lead to quality issues during moulding. The spray dryer effectively removes moisture, ensuring high-quality plastic products with enhanced mechanical properties.

Product Details:

Name: ZPG Series Spray Dryer

Heating Method: Steam Heating, powered by a combination of steam and electricity, ensures efficient heat transfer and temperature regulation.

Raw Material: Constructed from high-grade SS304/SS316L stainless steel, guaranteeing food safety in food applications and resistance to chemical corrosion in other sectors.

Evaporation Capacity: Ranges from 5-2000 kgs of water per hour, making it suitable for small-batch startups as well as large industrial operations.

Core Components: The motor drives essential functions such as the atomization of the feed liquid and the circulation of hot air, enabling smooth and continuous drying.

Weight: At 2000 kg, it’s a substantial piece of equipment, indicating its robustness and stability during operation.

Voltage: Compatible with 220v/380v power supplies, providing versatility in installation.

Warranty: 18 months, a testament to the manufacturer’s confidence in the product’s quality and reliability.

|

spec

|

ZPG-25

|

ZPG-50

|

ZPG-80

|

ZPG-100

|

ZPG-150

|

ZPG-200

|

ZPG-300

|

|

|

evaporation capacity(kg/h)

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

|

process amount of material liquid(kg/h)

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

|

output of finished pcoduct(kg/h)

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

24-42

|

36.8-56.4

|

55-85

|

|

|

solid content of material liquid( %)

|

18-30

|

|||||||

|

moisture content of finished product( %)

|

3-5

|

|||||||

|

electric power(kw)

|

63

|

132

|

153

|

204

|

246

|

330

|

||

|

heat source

|

Steam pius electricity

|

|||||||

|

Collecting method of product and its efficiency

|

Grade one or two or three stage cyclone wet dust remover is greater than or equal to 95%

|

|||||||

|

automatic control meters and instruments

|

indicator of not air and exhaust air temperature

|

|||||||

|

temperature of air inlet(℃)

|

160-220

|

|||||||

|

temperature of air outlet(℃)

|

80-100

|

|||||||

|

L

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15000

|

|

|

overal dimensions(mm)

|

W

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

H

|

6200

|

6900

|

8000

|

8900

|

10750

|

11900

|

13000

|

|

Specifications

|

spec

|

ZPG-25

|

ZPG-50

|

ZPG-80

|

ZPG-100

|

ZPG-150

|

ZPG-200

|

ZPG-300

|

|

|

evaporation capacity(kg/h)

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

|

process amount of material liquid(kg/h)

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

|

output of finished pcoduct(kg/h)

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

24-42

|

36.8-56.4

|

55-85

|

|

|

solid content of material liquid( %)

|

18-30

|

|||||||

|

moisture content of finished product( %)

|

3-5

|

|||||||

|

electric power(kw)

|

63

|

132

|

153

|

204

|

246

|

330

|

||

|

heat source

|

Steam pius electricity

|

|||||||

|

Collecting method of product and its efficiency

|

Grade one or two or three stage cyclone wet dust remover is greater than or equal to 95%

|

|||||||

|

automatic control meters and instruments

|

indicator of not air and exhaust air temperature

|

|||||||

|

temperature of air inlet(℃)

|

160-220

|

|||||||

|

temperature of air outlet(℃)

|

80-100

|

|||||||

|

L

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15000

|

|

|

overal dimensions(mm)

|

W

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

H

|

6200

|

6900

|

8000

|

8900

|

10750

|

11900

|

13000

|

|

Applications

Applicable Industries

1. food and beverage factories: ideal for large-scale coffee production, converting liquid coffee extracts into high-quality powdered coffee products with consistent quality and flavour. 2. food stores: can be used in-house.

2. food outlets: for in-house coffee roasting and drying operations to create unique coffee blends and speciality coffee powders. 3. food service outlets: for small to medium-sized coffee roasting and drying operations.

3. food service establishments: for small to medium-sized coffee dryings needs, such as producing custom coffee additives or processing coffee on-site to enhance freshness and flavour.

Yutong’s spray dry coffee machines are a reliable, efficient and versatile solution that combines advanced technology, quality materials and comprehensive after-sales support, making them the best choice for a wide range of applications in food and chemical processing.