Table of Contents

Product Detail

Basic principle

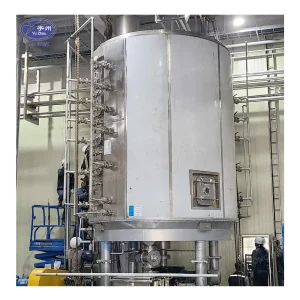

This machine is a new type of intermittent vacuum drying equipment, wet material by conduction evaporation with a scraper agitator will remove material on the hot surface, and move in the container to form a circulation flow of water evaporation by the vacuum pump.

ZKG vacuum harrow drying equipment is a new type of high-efficiency horizontal vacuum drying equipment. adopts jacketed structure, and the jacket can be heated by steam, hot water or conduction oil—the jacket transfers the heat to the inner wall of the shell via conduction or radiation. The dried materials are added into the dryer through an opening in the middle of the machine shell. Constant stirring of the revolving harrow causes the materials move back and forth. The surface contact with the shell’s inner wall constantly updates, resulting in high drying rate and uniform finished products.

Main Features

1) ZKG vacuum harrow drying equipment uses large-area inter-layer heating to obtain large heat-trans.

fer surface and high heat efficiency.

2) This vacuum drying equipment with a stirring device can improve the heating uniformity and smoothly dry

slurry and pasty materials.

3) lt is easy to operate and clean, which can effectively reduce labor intensity

4) lf this vacuum harrow dryer adopts internal concurrent heating, the heating area will be greatly increased

Specifications

|

Model

|

Volume (L)

|

Working Volume (L)

|

Heating Area (m2)

|

Stirring Rate (rmp)

|

Power (kw)

|

Interlayer Pressure (Mpa)

|

Pressure in the Container (Mpa)

|

|

ZKG-500

|

500

|

300

|

3.2

|

8 to 18

|

4

|

0.3

|

-0.096 to 0.15

|

|

ZKG-750

|

750

|

450

|

4.4

|

8 to 18

|

5.5

|

0.3

|

-0.096 to 0.15

|

|

ZKG-1000

|

1000

|

600

|

5.1

|

8 to 18

|

5.5

|

0.3

|

-0.096 to 0.15

|

|

ZKG-1500

|

1500

|

900

|

6.3

|

8 to 18

|

7.5

|

0.3

|

-0.096 to 0.15

|

|

ZKG-2000

|

2000

|

1200

|

8.1

|

8 to 18

|

7.5

|

0.3

|

-0.096 to 0.15

|

|

ZKG-3000

|

3000

|

1800

|

10.6

|

8 to 18

|

11

|

0.3

|

-0.096 to 0.15

|

|

ZKG-4000

|

4000

|

2400

|

12.3

|

8 to 18

|

15

|

0.3

|

-0.096 to 0.15

|

|

ZKG-5000

|

5000

|

300

|

14.2

|

8 to 18

|

18.5

|

0.3

|

-0.096 to 0.15

|

|

ZKG-6000

|

6000

|

3600

|

16.5

|

8 to 18

|

22

|

0.3

|

-0.096 to 0.15

|

Applications

Applicable Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Retail, Food & Beverage Shops, government