Table of Contents

Product Detail

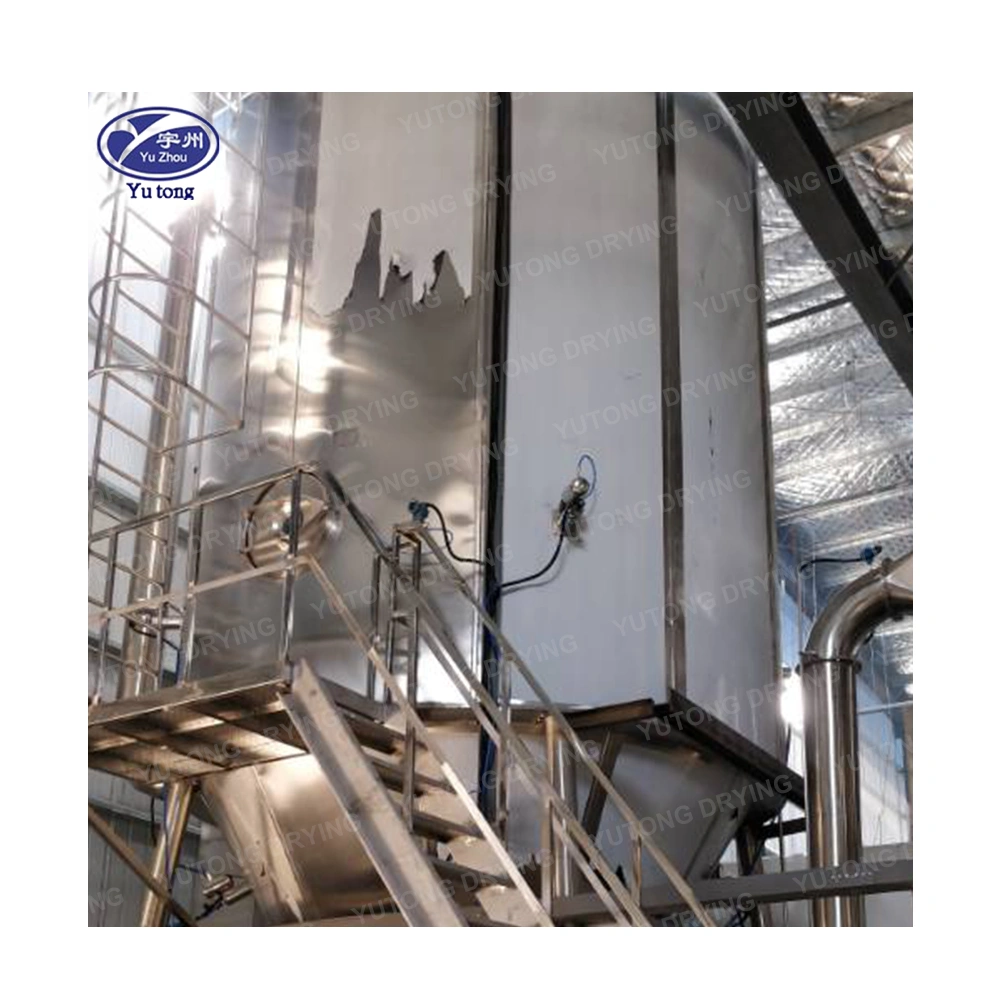

Milk Spray Dryer Product Details

Main Features

Temperature Control and Prevention of Product Issues: The tower body is equipped with a cool air jacket, which helps reduce the inside tower temperature and effectively eliminates the preheating and softening of the product. Additionally, the atomizer on top of the tower has a cooling device to lower its temperature, preventing material from returning to the top due to eddy currents and avoiding preheat coking.

Easy Cleaning and Maintenance: The tower body and pipeline are designed with manual quick-open cleaning holes and drainage holes, facilitating easy cleaning. Moreover, a CIP automatic cleaning device can be optionally installed for more efficient and thorough cleaning.

Feeding System: An automatic control constant temperature feeding tank can be equipped, ensuring a stable and consistent feed of the milk product, which is crucial for the quality and efficiency of the drying process.

Accessories and Material Quality: Manual high-pressure washing tools are provided as accessories, making it convenient for users to clean the equipment. All product contact parts are made of stainless steel, or the entire unit can be constructed with stainless steel, ensuring hygiene, durability, and resistance to corrosion.

Product Collection: The product collection method employs two-stage cyclones and a water film duster, which work together to effectively separate and collect the dried milk powder, improving the collection efficiency and product quality.

Temperature and Process Control: The air inlet temperature is automatically and continuously controlled and is interlocked with the feeding system. This precise control ensures that the drying process is optimized based on the feed rate, resulting in consistent product quality. Additionally, an air sweeping device is available as an option for certain products, further enhancing the drying and collection process.

Application

This milk spray dryer is specifically designed for use in food processing, particularly for drying milk and related dairy products. It can also be applied in other food-related industries for drying various liquid or semi-liquid food materials.

Warranty

The product comes with a 2-year warranty, providing customers with long-term assurance of its quality and performance.

The core components, namely the gear, motor, and gearbox, have a 1-year warranty, reflecting the manufacturer’s confidence in the durability and reliability of these key parts.

Weight

The milk spray dryer weighs 1300 KG, and this weight should be taken into account during installation and transportation to ensure proper handling and placement.

Voltage

The voltage options for this milk spray dryer are 380V and 220V, with customization available to meet the specific power supply requirements of different users and locations, offering flexibility in installation and operation.

Applicable Industries

This milk spray dryer is not only suitable for food & beverage factories but also has wide applicability in other industries such as building material shops, manufacturing plants, machinery repair shops, farms, restaurants, and retail. This demonstrates its versatility and broad market potential, as it can be used in various settings where drying of milk or other similar substances is required.

Basic Principle: High-speed centrifuge atomizing for the extract of traditional Chinese medicine is an application of centrifuge atomizing technique. LT also uses a high-speed atomizer to make liquid material into foggy droplets to contact with hot air fully to finish instant drying and get the final powder product.

Main Features1) The tower body is equipped with a cool air jacket to reduce inside tower temperature and eliminate product preheating and softening phenomenon

2) The atomizer on top of the tower is equipped with a cooling device to reduce atomizer temperature, effectively eliminating material return to the top in eddy current and avoiding the preheat coking phenomenon) The Tower body and pipeline are equipped with a manual quick-open cleaning hole and drainage hole. ClP automatic cleaning device can also equipped if needed.

4) An automatic control constant temperature feeding tank can be equipped

5) Manual high-pressure washing tools can be offered as accessories together with a spray dryer.6) All product contact parts are made with Stainless Steel (or whole parts with stainless steel)7) The Product collect way adopts two-grade cyclones and a water film duster.

6) Air inlet temperature is automatic and continuous control which is interlocked with feeding9)An air sweeping device can be optional for some products

Specifications

|

spec

|

ZPG-25

|

ZPG-50

|

ZPG-80

|

ZPG-100

|

ZPG-150

|

ZPG-200

|

ZPG-300

|

|

|

evaporation capacity(kg/h)

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

|

process amount of material liquid(kg/h)

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

|

output of finished pcoduct(kg/h)

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

24-42

|

36.8-56.4

|

55-85

|

|

|

solid content of material liquid( %)

|

18-30

|

|||||||

|

moisture content of finished product( %)

|

3-5

|

|||||||

|

electric power(kw)

|

63

|

132

|

153

|

204

|

246

|

330

|

||

|

heat source

|

Steam pius electricity

|

|||||||

|

Collecting method of product and its efficiency

|

Grade one or two or three stage cyclone wet dust remover is greater than or equal to 95%

|

|||||||

|

automatic control meters and instruments

|

indicator of not air and exhaust air temperature

|

|||||||

|

temperature of air inlet(℃)

|

160-220

|

|||||||

|

temperature of air outlet(℃)

|

80-100

|

|||||||

|

L

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15000

|

|

|

overal dimensions(mm)

|

W

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

H

|

6200

|

6900

|

8000

|

8900

|

10750

|

11900

|

13000

|

|

Applications

Applicable Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Retail, Food & Beverage Shops