Table of Contents

Product Detail

Spray drying is a popular technique used across various industries, including pharmaceuticals, food processing, and chemicals. This method transforms liquid substances into dry powder form, offering advantages like increased shelf life and easier transportation. One of the critical types of spray dryers is the GMP (Good Manufacturing Practice) spray dryer, which ensures the highest quality and compliance standards are met, which is especially crucial in the pharmaceutical industry.

In this article, we’ll delve into what makes GMP spray dryers essential, their applications, and how they differ from other types of spray dryers.

What is a GMP Spray Dryer?

A GMP spray dryer is designed to meet the stringent requirements of Good Manufacturing Practices, ensuring product safety, quality, and purity. These dryers are typically used in industries where hygiene and precision are paramount, such as pharmaceuticals and food processing. A GMP spray dryer must comply with regulatory guidelines, which include strict material handling, equipment cleaning, and process validation standards.

Ensuring Product Safety

Ensuring product safety is a primary concern in the design of GMP spray dryers. These dryers must be constructed from materials that do not interact with the product, avoiding any contamination. Regular maintenance and checks are crucial to ensure that each component remains in optimal condition, preventing any potential hazards.

Compliance with Regulatory Guidelines

GMP spray dryers must adhere to various regulatory guidelines, which dictate how they should be constructed and operated. This includes meeting the standards set by organizations like the FDA or EMA, ensuring that all processes are documented, and that the equipment undergoes regular audits. Compliance ensures that the production process remains consistent and within the legal framework.

Precision and Hygiene in Operations

Precision and hygiene are non-negotiable in industries that rely on GMP spray dryers. The equipment must allow for precise control over the drying process, ensuring that each batch maintains uniform quality. Additionally, the design should facilitate easy cleaning to prevent cross-contamination between different production cycles.

Key Features of GMP Spray Dryers

Compliance with Industry Standards

GMP spray dryers are built to adhere to industry-specific regulations. This includes using materials that are safe for pharmaceutical use and ensuring the equipment can be thoroughly cleaned to avoid cross-contamination.

Material Selection and Safety

The selection of materials for GMP spray dryers is critical, as they must be inert and non-reactive to the substances being dried. Stainless steel is often used due to its resistance to corrosion and ease of cleaning, reducing the risk of contamination. Moreover, regular inspections ensure that all materials continue to meet safety standards.

Cleaning and Maintenance Protocols

To maintain compliance with industry standards, GMP spray dryers must have rigorous cleaning and maintenance protocols. These protocols are designed to ensure that the equipment remains free from contaminants and operates efficiently. Detailed records of cleaning procedures are maintained to facilitate audits and inspections.

Adherence to Regulatory Frameworks

Adhering to regulatory frameworks involves not just meeting current standards but also staying updated with any changes in regulations. This proactive approach ensures that GMP spray dryers remain compliant and operational, avoiding potential disruptions in production.

Customization and Flexibility

Many manufacturers offer customized spray dryers to meet specific needs. Whether you require a vector spray dryer or a closed-loop spray dryer, customization options allow for flexibility in design and operation.

Tailored Design Solutions

Customization in GMP spray dryers allows for tailored design solutions that meet the unique requirements of different industries. This includes modifications to the size, shape, and capacity of the dryers, enabling them to handle specific types of products more effectively.

Adaptable Operational Features

Operational flexibility is another key aspect of customized GMP spray dryers. Features such as adjustable drying temperatures, variable airflow rates, and customizable control systems allow operators to fine-tune the drying process for different products, ensuring optimal results.

Meeting Diverse Industry Needs

Different industries have diverse needs when it comes to spray drying, and customization helps meet these requirements effectively. From pharmaceuticals to food processing, each sector can benefit from specialized features that enhance the efficiency and safety of the drying process.

Advanced Technology

Modern GMP spray dryers incorporate advanced technology to ensure precise control over the drying process. This can include automated systems for monitoring and adjusting temperature, airflow, and pressure, ensuring consistent product quality.

Automation and Control Systems

The incorporation of automation and advanced control systems in GMP spray dryers enhances precision and efficiency. These systems allow for real-time monitoring and adjustments, ensuring that drying parameters remain optimal throughout the process. This results in improved product consistency and reduced human error.

Integration of IoT and Data Analytics

The integration of Internet of Things (IoT) technology and data analytics in GMP spray dryers represents a significant advancement. IoT enables remote monitoring and control, while data analytics provides insights into the drying process, identifying areas for improvement and optimizing performance.

Continuous Innovation and Upgrades

Continuous innovation in technology ensures that GMP spray dryers remain at the forefront of industry standards. Manufacturers regularly introduce upgrades and new features, allowing businesses to stay competitive and maintain high-quality production processes.

Safety and Efficiency

Safety features are paramount in GMP spray dryers to protect operators and maintain product integrity. Efficient designs help reduce energy consumption and operational costs.

Operator Safety Measures

Ensuring the safety of operators is a top priority in the design of GMP spray dryers. This includes features such as emergency shut-off systems, safety interlocks, and protective enclosures to minimize the risk of accidents and exposure to hazardous materials.

Energy Efficiency and Cost Reduction

Efficient design elements in GMP spray dryers contribute to reduced energy consumption and operational costs. Innovations such as heat recovery systems, optimized airflow patterns, and energy-efficient components help minimize the environmental impact and enhance the sustainability of the drying process.

Maintaining Product Integrity

Maintaining product integrity involves ensuring that the drying process does not alter the essential properties of the product. GMP spray dryers are designed to provide gentle and uniform drying, preserving the quality and efficacy of the final product.

Applications of GMP Spray Dryers

Pharmaceutical Industry

In the pharmaceutical industry, GMP spray dryers are used to produce dry powders for various applications, including active pharmaceutical ingredients (APIs), excipients, and final dosage forms. The high level of control over the drying process ensures that the resulting powders have the desired particle size distribution and properties.

Production of Active Pharmaceutical Ingredients (APIs)

GMP spray dryers play a vital role in the production of APIs, where precise control over particle size and distribution is crucial. This ensures that the active ingredients maintain their potency and efficacy, contributing to the effectiveness of the final pharmaceutical products.

Formulation of Excipients

Excipients, which are inactive substances used as carriers for active ingredients, require careful drying to maintain their stability and functionality. GMP spray dryers enable the production of high-quality excipients with consistent properties, which is essential for successful drug formulation.

Manufacturing of Final Dosage Forms

The manufacturing of final dosage forms, such as tablets and capsules, often involves spray drying processes. GMP spray dryers ensure that these products meet stringent quality standards, providing patients with safe and effective medications.

Food Industry

GMP spray dryers are also used in the food industry to produce powdered food products such as milk powder, coffee, and flavorings. The ability to maintain product quality and safety standards is crucial in this sector.

Production of Dairy Products

In the dairy industry, GMP spray dryers are employed to produce milk powder and other dairy-based products. This process extends the shelf life of these products while preserving their nutritional content and flavor, meeting consumer demands for convenience and quality.

Creation of Instant Beverages

Instant beverages, such as coffee and tea, benefit from spray-drying processes that enhance their solubility and flavor retention. GMP spray dryers ensure that these products meet high-quality standards, providing consumers with a satisfying and reliable product experience.

Development of Flavorings and Additives

Flavorings and additives are essential components in many food products, and GMP spray dryers facilitate their production with precision and consistency. This ensures that the final food products have the desired taste and aroma, appealing to consumers’ preferences.

Chemical Industry

In the chemical industry, GMP spray dryers are employed to produce fine chemicals and specialty products. The precise control over drying parameters ensures consistent product quality and performance.

Synthesis of Specialty Chemicals

Specialty chemicals used in various industrial applications require precise production processes to achieve the desired characteristics. GMP spray dryers enable the synthesis of these chemicals with consistent quality, meeting the specific requirements of different industries.

Production of Catalysts and Enzymes

Catalysts and enzymes are critical components in many chemical reactions, and their production demands high precision. GMP spray dryers ensure that these products have the required activity and stability, contributing to the efficiency of industrial processes.

Manufacturing of Pigments and Dyes

The manufacturing of pigments and dyes involves the production of fine powders with specific color properties. GMP spray dryers provide the control needed to achieve uniform particle size and distribution, ensuring consistent color quality in the final products.

Types of Spray Dryers

Closed Loop Spray Dryer

Closed-loop spray dryers are designed to recycle the drying gas, which can be beneficial when dealing with flammable or toxic materials. This type of dryer minimizes environmental impact and enhances safety.

Recycling and Environmental Benefits

Closed-loop spray dryers contribute to environmental sustainability by recycling the drying gas, reducing emissions, and minimizing waste. This approach aligns with the growing emphasis on eco-friendly manufacturing practices across industries.

Handling of Hazardous Materials

When dealing with flammable or toxic materials, closed-loop spray dryers provide a safe and controlled environment. The closed system minimizes the risk of exposure and ensures that potentially harmful substances are contained, protecting both operators and the environment.

Applications in Sensitive Industries

Closed-loop spray dryers are ideal for industries that handle sensitive or hazardous materials, such as pharmaceuticals and chemicals. Their ability to safely manage these substances while maintaining high-quality production standards makes them a preferred choice in these sectors.

Toll Processing Spray Dryer

Toll processing involves outsourcing spray drying operations to a third-party service provider. Toll processing spray dryer services, such as those available in Mexico, allow companies to benefit from specialized expertise and equipment without the need for significant capital investment.

Benefits of Outsourcing

Outsourcing spray drying operations through toll processing allows companies to access specialized expertise and advanced equipment without the need for significant capital investment. This approach can enhance production efficiency and reduce operational costs, providing a competitive advantage.

Access to Specialized Facilities

Toll processing service providers offer access to state-of-the-art facilities and equipment, enabling companies to produce high-quality products without the need to invest in their own infrastructure. This can be particularly beneficial for small and medium-sized enterprises looking to expand their production capabilities.

Flexibility and Scalability

Toll processing provides flexibility and scalability, allowing companies to adjust their production volumes based on demand. This approach enables businesses to respond quickly to market changes and seize new opportunities without the constraints of fixed production capacities.

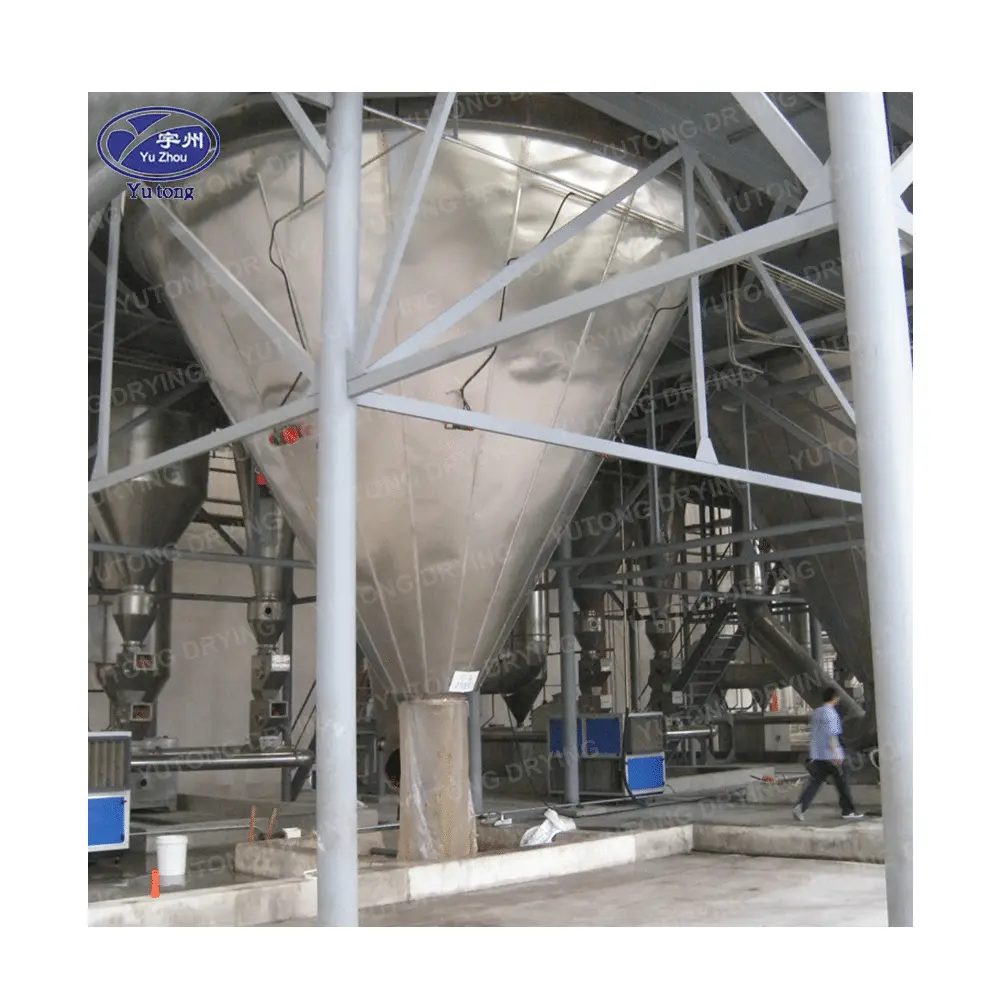

Largest Spray Dryer in the World

The largest spray dryer in the world is a marvel of engineering, capable of processing massive quantities of material. Such large-scale operations are typically found in industries with high-volume production requirements.

Engineering and Design Challenges

Designing and constructing the largest spray dryer in the world involves overcoming significant engineering challenges. These include ensuring structural integrity, optimizing airflow dynamics, and maintaining energy efficiency, all while accommodating the massive scale of operations.

Applications in High-Volume Industries

Industries with high-volume production requirements, such as food processing and chemicals, benefit from the capabilities of the largest spray dryer in the world. These large-scale operations enable efficient processing of vast quantities of material, meeting the demands of global markets.

Innovations and Technological Advancements

The development of the largest spray dryer in the world showcases innovations and technological advancements in the field of spray drying. These innovations contribute to improved efficiency, reduced environmental impact, and enhanced product quality, setting new standards for the industry.

Understanding Spray Dryer Size Distribution

The size distribution of particles produced by a spray dryer is a critical factor in determining the quality and performance of the final product. A well-designed spray dryer will produce a narrow size distribution, ensuring uniformity and consistency.

Importance of Particle Size Distribution

Particle size distribution is crucial in determining the quality and performance of the final product. Consistent particle size ensures uniformity in the product’s properties, such as solubility, stability, and bioavailability, which are essential for meeting industry standards and consumer expectations.

Factors Influencing Particle Size

Several factors influence the particle size distribution in spray drying, including nozzle design, feed concentration, and drying parameters. Understanding and controlling these factors is key to achieving the desired particle size and ensuring consistent product quality.

Nozzle Design and Configuration

The design and configuration of the spray nozzle significantly impact particle size distribution. Different nozzle types, such as rotary or pressure nozzles, offer varying degrees of control over droplet size, affecting the final particle size and uniformity.

Feed Concentration and Viscosity

Feed concentration and viscosity play a crucial role in determining particle size during spray drying. Higher concentrations typically lead to larger particles, while viscosity affects droplet formation and drying dynamics, influencing the final product properties.

Drying Parameters and Conditions

Drying parameters, such as temperature, pressure, and airflow, are critical in controlling particle size distribution. Precise adjustment of these parameters ensures optimal drying conditions, resulting in consistent and high-quality products.

Validation and Documentation in GMP Spray Dryers

Validation is a crucial aspect of operating a GMP spray dryer. This process ensures that the equipment consistently produces products that meet predetermined specifications. Key validation steps include:

Importance of Validation

Validation is essential in ensuring that GMP spray dryers consistently produce products that meet quality standards and regulatory requirements. This process involves verifying that the equipment and processes perform as intended, assuring product safety and efficacy.

Key Validation Steps

The validation process for GMP spray dryers involves several key steps, including Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ). Each step plays a vital role in confirming that the equipment and processes meet specified criteria and function correctly.

Installation Qualification (IQ)

Installation Qualification (IQ) involves verifying that the GMP spray dryer is installed according to specifications and manufacturer guidelines. This step ensures that the equipment is set up correctly and ready for operation, providing a solid foundation for subsequent validation stages.

Operational Qualification (OQ)

Operational Qualification (OQ) focuses on confirming that the GMP spray dryer operates according to specified parameters. This involves testing the equipment under various conditions to ensure it performs reliably and consistently, meeting the required performance standards.

Performance Qualification (PQ)

Performance Qualification (PQ) demonstrates that the GMP spray dryer consistently produces products that meet the desired quality specifications. This step involves rigorous testing and evaluation of the equipment’s performance in real-world production scenarios, ensuring that the final products comply with industry standards.

Comprehensive Documentation

Comprehensive documentation is essential throughout the validation process to ensure compliance and facilitate audits. Detailed records of validation activities, test results, and process parameters provide a transparent and traceable history of the equipment’s performance, supporting quality assurance efforts.

Key Players in the GMP Spray Dryer Market

Several companies specialize in manufacturing GMP spray dryers, each offering unique features and capabilities. Some notable players include:

Freund Vector Spray Dryer

Freund Vector Spray Dryer is known for its innovative designs and advanced technology. The company’s focus on research and development ensures that its products remain at the forefront of industry standards, providing customers with cutting-edge solutions for their spray drying needs.

Procept Spray Dryer

Procept Spray Dryer offers a range of customizable options to meet specific industry needs. The company’s commitment to flexibility and adaptability allows it to provide tailored solutions that address the unique requirements of different sectors, enhancing production efficiency and product quality.

Icon Spray Dryer

Icon Spray Dryer specializes in high-efficiency designs that reduce energy consumption and operational costs. The company’s focus on sustainability and cost-effectiveness makes its products an attractive choice for businesses looking to optimize their spray drying processes while minimizing environmental impact.

Conclusion

GMP spray dryers play a vital role in industries where product quality and safety are paramount. By adhering to stringent manufacturing standards, these dryers ensure that the final products meet the highest quality requirements. Whether you’re in the pharmaceutical, food, or chemical industry, investing in a GMP spray dryer can enhance your production capabilities and ensure compliance with industry regulations.

Emphasizing the Importance of Quality and Safety

The importance of quality and safety in the production process cannot be overstated, and GMP spray dryers provide the necessary tools to achieve these goals. By maintaining stringent standards, businesses can ensure that their products meet consumer expectations and regulatory requirements, building trust and credibility in the market.

Exploring Diverse Applications

The diverse applications of GMP spray dryers across various industries highlight their versatility and value. From pharmaceuticals to food processing, these dryers offer solutions that enhance efficiency, quality, and safety, supporting the growth and success of businesses in competitive markets.

Looking Ahead: The Future of GMP Spray Dryers

As technology continues to evolve, GMP spray dryers will remain an essential tool for producing high-quality, safe, and effective products. Innovations in automation, data analytics, and sustainability will drive further advancements, ensuring that these dryers continue to meet the changing needs of industries and consumers alike.

Specifications

|

spec

|

ZPG-25

|

ZPG-50

|

ZPG-80

|

ZPG-100

|

ZPG-150

|

ZPG-200

|

ZPG-300

|

|

|

evaporation capacity(kg/h)

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

|

process amount of material liquid(kg/h)

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

|

output of finished pcoduct(kg/h)

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

24-42

|

36.8-56.4

|

55-85

|

|

|

solid content of material liquid( %)

|

18-30

|

|||||||

|

moisture content of finished product( %)

|

3-5

|

|||||||

|

electric power(kw)

|

63

|

132

|

153

|

204

|

246

|

330

|

||

|

heat source

|

Steam pius electricity

|

|||||||

|

Collecting method of product and its efficiency

|

Grade one or two or three stage cyclone wet dust remover is greater than or equal to 95%

|

|||||||

|

automatic control meters and instruments

|

indicator of not air and exhaust air temperature

|

|||||||

|

temperature of air inlet(℃)

|

160-220

|

|||||||

|

temperature of air outlet(℃)

|

80-100

|

|||||||

|

L

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15000

|

|

|

overal dimensions(mm)

|

W

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

H

|

6200

|

6900

|

8000

|

8900

|

10750

|

11900

|

13000

|

|

Applications

No Content Matching Your Selection Is Found.