Table of Contents

Product Detail

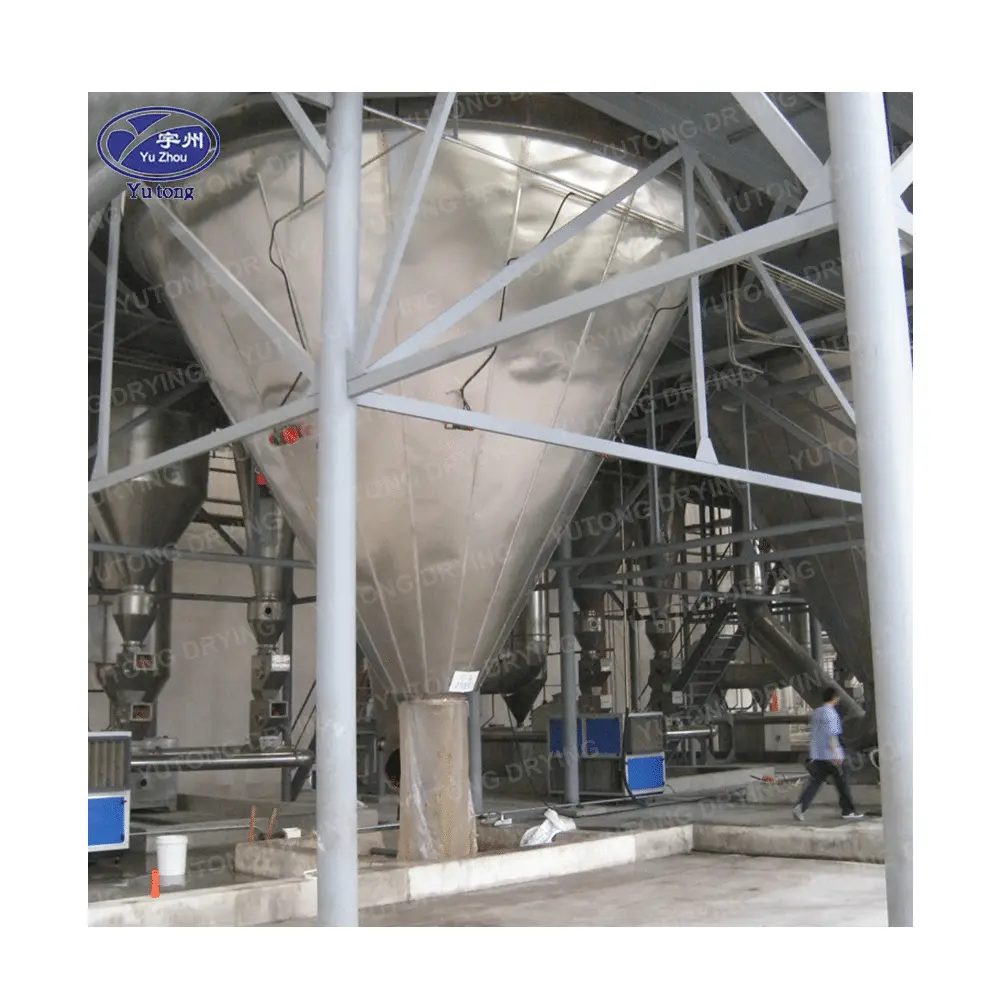

In the heart of New Zealand’s bustling Waikato region lies a marvel of modern food technology – the Food Waikato Spray Dryer. This cutting-edge facility at Waikato Innovation Park is transforming the way we think about food preservation and production. With its advanced capabilities, it is paving the way for innovation in the dairy and food industries, offering new solutions for entrepreneurs and established businesses alike. This facility is not just a technological asset but a beacon of progress, signaling a shift towards more efficient and sustainable food processing methods.

The Technology Behind the Food Waikato Spray Dryer

The Food Waikato Spray Dryer utilizes a sophisticated process of drying liquid food products into powder form. This method, known as spray drying, involves atomizing liquid into a fine mist and then introducing it to hot air. The moisture rapidly evaporates, leaving behind dry particles or powder. This process is incredibly effective in preserving the nutritional quality and flavor of the food, making it an essential tool for food manufacturers. The precision of this method allows for consistent quality in the end products, which is crucial for meeting industry standards and consumer expectations.

How Spray Drying Works

The spray drying process begins with the preparation of the liquid food product, which is often homogenized to ensure uniformity. This liquid is then fed into a spray nozzle, where it is atomized into tiny droplets. These droplets are introduced into a chamber with hot air, causing the moisture to evaporate almost instantly. The result is a fine powder that retains the essential properties of the original liquid.

Technological Advancements

Recent advancements in spray drying technology have focused on improving energy efficiency and reducing environmental impact. Innovations such as heat recovery systems and advanced control mechanisms ensure that the process consumes less energy while maintaining high-quality output. Additionally, the development of more sophisticated nozzles and drying chambers has allowed for greater control over particle size and product consistency.

Quality Control Measures

Quality control is a critical component of the spray drying process. Rigorous testing is conducted at various stages to ensure that the powders meet specified standards for moisture content, particle size, and nutrient retention. Advanced analytical tools monitor the process in real-time, allowing for immediate adjustments if necessary. This ensures that the final product is not only safe but also meets consumers’ nutritional and sensory expectations.

Environmental Considerations

The environmental footprint of spray drying is a growing concern, prompting the industry to adopt more sustainable practices. By optimizing energy use and minimizing waste, the Food Waikato Spray Dryer exemplifies how modern facilities can balance productivity with environmental stewardship. Efforts are also underway to explore alternative energy sources, such as solar and wind, to power the drying process.

Benefits of Spray Drying

Spray drying offers numerous benefits over traditional drying techniques. Here are some key advantages:

Nutritional Integrity

The gentle drying process helps retain the nutrients, ensuring that the end product is as healthy as possible. Unlike other methods that may degrade heat-sensitive nutrients, spray drying preserves vitamins and proteins, maintaining the food’s nutritional value. This makes it an ideal choice for health-focused products, where nutrient retention is paramount.

Extended Shelf Life

By removing moisture, the shelf life of food products is significantly increased, reducing waste and improving storage efficiency. The absence of water inhibits microbial growth, which is a primary cause of spoilage. This prolongation of shelf life is particularly beneficial for products that are distributed globally, where transport times can be lengthy.

Cost Efficiency

Spray drying is an efficient process that can handle large volumes, reducing production costs and making it an attractive option for businesses. Converting liquids into powders reduces packaging and transportation costs, as powders are lighter and more compact. This efficiency translates into lower overheads and increased profitability for manufacturers.

Versatility

It is suitable for a wide range of products, including dairy, fruits, vegetables, and more. Spray drying’s adaptability allows manufacturers to experiment with different formulations, leading to innovative products that cater to evolving consumer demands. This versatility also means that companies can diversify their product lines without significant additional investment.

Consistency and Quality

Spray drying ensures a high level of consistency in product quality, which is crucial for maintaining brand reputation. The process produces uniform particles, resulting in powders that dissolve quickly and evenly, providing a consistent experience for consumers. This reliability is a significant advantage in competitive markets where consumer trust is vital.

Applications of the Food Waikato Spray Dryer

The Food Waikato Spray Dryer’s versatility extends to various applications, making it a valuable asset for many sectors.

Dairy Industry

The dairy industry is one of the primary beneficiaries of spray drying technology. Milk powder, a staple in many households, is produced using this method. It allows for the production of infant formulas, dietary supplements, and other dairy products that require extended shelf life and ease of transport. The ability to produce high-quality dairy powders is essential for meeting the demands of international markets, where dairy consumption is on the rise.

Nutraceuticals and Functional Foods

Nutraceuticals are gaining popularity due to their health benefits. The spray dryer facilitates the creation of functional foods that are fortified with vitamins and minerals. This ensures that consumers receive the maximum nutritional value without compromising on taste. The demand for functional foods is growing as consumers become more health-conscious and seek products that support their well-being.

Fruit and Vegetable Powders

Spray drying is also used to create fruit and vegetable powders, which are convenient for use in beverages, baking, and seasoning. These powders retain their natural flavors and colors, offering consumers a taste of freshness in every sprinkle. The ability to produce vibrant, flavorful powders opens up new possibilities for food manufacturers looking to innovate and attract health-conscious consumers.

Pharmaceuticals

In the pharmaceutical industry, spray drying is used to create powdered drugs that are easier to handle and administer. The precise control over particle size and composition is crucial for ensuring the effectiveness of these medications. This application of spray drying is vital for developing new drug formulations that improve patient compliance and therapeutic outcomes.

Pet Food and Animal Nutrition

The pet food industry also benefits from spray drying technology, which produces nutrient-dense powders for pet diets. These powders can be added to kibble or used in treats, enhancing the nutritional profile of pet food products. The ability to produce consistent, high-quality powders ensures that pets receive the essential nutrients they need for optimal health.

Innovating at Waikato Innovation Park

Waikato Innovation Park is a hub for technological advancement and collaboration. The presence of the spray dryer at this facility underscores its commitment to fostering innovation and supporting local businesses. By providing access to state-of-the-art technology, Waikato Innovation Park enables companies to test and develop new products without the need for significant capital investment. This environment of innovation and support is crucial for driving the industry forward and maintaining a competitive edge in the global market.

Supporting Startups and Entrepreneurs

The spray dryer is an invaluable resource for startups and small businesses looking to bring new products to market. The ability to test small batches before scaling up production helps reduce risk and ensure product quality. This support is crucial for entrepreneurs aiming to make their mark in the competitive food industry. By offering access to advanced technology, Waikato Innovation Park lowers the barriers to entry, encouraging innovation and entrepreneurship.

Collaboration and Research

Waikato Innovation Park encourages collaboration between industry experts, researchers, and businesses. This environment of shared knowledge and resources accelerates the development of innovative food preservation techniques and products, driving the industry forward. Collaborative research projects benefit from the diverse expertise available at the park, leading to breakthroughs that might not be possible in isolation.

Training and Education

The park also plays a critical role in training and education, providing opportunities for students and professionals to learn about the latest advancements in food technology. Workshops, seminars, and hands-on training sessions help build a skilled workforce that is capable of meeting the demands of the evolving food industry. This commitment to education ensures that the next generation of food scientists and technologists is well-prepared to continue the legacy of innovation.

Community Engagement

Waikato Innovation Park is deeply committed to engaging with the local community, offering tours and educational events to raise awareness about the importance of food technology. By showcasing the potential of the spray dryer and other innovations, the park inspires future generations to pursue careers in science and technology. This engagement fosters a sense of pride and ownership within the community, reinforcing the park’s role as a leader in food technology.

Advancing Food Preservation Techniques

The Food Waikato Spray Dryer is at the forefront of advancing food preservation techniques. Its capabilities have opened new avenues for research and development, leading to breakthroughs in how we preserve and consume food.

Sustainable Practices

Spray drying aligns with sustainable practices by minimizing waste and reducing the carbon footprint associated with food production and transportation. The longer shelf life of products also contributes to reducing food waste, a significant concern in today’s world. By adopting sustainable practices, the industry can meet consumer demand for environmentally friendly products while preserving natural resources for future generations.

Enhancing Global Food Security

Spray drying plays a vital role in enhancing global food security by providing a means to preserve food for extended periods. It allows for the transportation of essential nutrients to areas that may lack fresh produce, ensuring that populations have access to nutritious food year-round. This capability is critical in regions affected by climate change or political instability, where food supply chains may be disrupted.

Innovations in Product Development

The spray dryer’s capabilities facilitate innovations in product development, allowing companies to experiment with new formulations and flavors. This experimentation leads to the creation of novel products that cater to diverse consumer preferences and dietary needs. The ability to rapidly prototype and test new products accelerates the pace of innovation, enabling companies to respond quickly to market trends.

Enhancing Nutrient Bioavailability

Recent research has focused on using spray drying to enhance the bioavailability of nutrients, making them more readily absorbed by the body. This is particularly important for developing functional foods and supplements that deliver targeted health benefits. By optimizing the spray drying process, manufacturers can produce powders that maximize nutrient delivery and efficacy.

Conclusion

The Food Waikato Spray Dryer at Waikato Innovation Park represents a significant leap forward in food technology. Its ability to transform liquid products into stable, nutrient-rich powders is revolutionizing the way we approach food preservation and production. For businesses, entrepreneurs, and researchers, the spray dryer offers a wealth of opportunities to innovate and improve product offerings. As we continue to explore the possibilities of this remarkable technology, the future of food looks increasingly promising and sustainable.

In summary, the Food Waikato Spray Dryer is not just a tool; it is a catalyst for change, driving the food industry toward a more efficient and sustainable future. Its impact extends beyond immediate technological advancements, influencing global food security, sustainability, and the very nature of food consumption. As such, it embodies the spirit of innovation and progress that is essential for addressing the challenges of the modern food industry.

Specifications

|

spec

|

ZPG-25

|

ZPG-50

|

ZPG-80

|

ZPG-100

|

ZPG-150

|

ZPG-200

|

ZPG-300

|

|

|

evaporation capacity(kg/h)

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

|

process amount of material liquid(kg/h)

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

|

output of finished pcoduct(kg/h)

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

24-42

|

36.8-56.4

|

55-85

|

|

|

solid content of material liquid( %)

|

18-30

|

|||||||

|

moisture content of finished product( %)

|

3-5

|

|||||||

|

electric power(kw)

|

63

|

132

|

153

|

204

|

246

|

330

|

||

|

heat source

|

Steam pius electricity

|

|||||||

|

Collecting method of product and its efficiency

|

Grade one or two or three stage cyclone wet dust remover is greater than or equal to 95%

|

|||||||

|

automatic control meters and instruments

|

indicator of not air and exhaust air temperature

|

|||||||

|

temperature of air inlet(℃)

|

160-220

|

|||||||

|

temperature of air outlet(℃)

|

80-100

|

|||||||

|

L

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15000

|

|

|

overal dimensions(mm)

|

W

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

H

|

6200

|

6900

|

8000

|

8900

|

10750

|

11900

|

13000

|

|

Applications

No Content Matching Your Selection Is Found.