Table of Contents

Product Detail

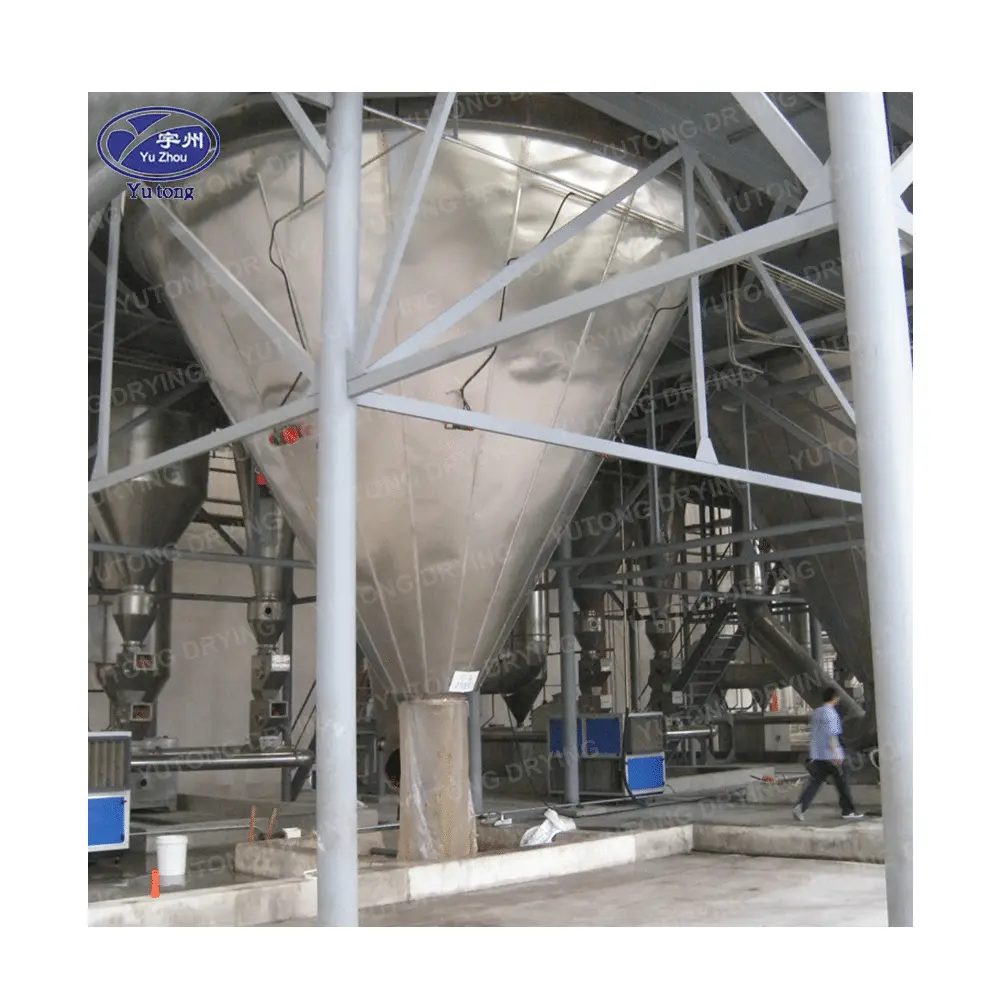

egg powder spray dryer

In the evolving landscape of food technology, egg powder has gained prominence as a versatile ingredient, offering significant advantages in terms of storage, shelf life, and wide-ranging applications. Central to this transformation is the egg powder spray dryer—a pivotal piece of equipment that converts liquid eggs into powder. This article delves deep into the intricacies of egg powder spray dryers, their manifold applications, and where they can be sourced, particularly in Rio de Janeiro.

Understanding Egg Protein Powder

Before exploring the technicalities of the spray dryer, it’s crucial to grasp what egg protein powder is. Essentially, it’s a dehydrated form of egg that maintains its nutritional profile, providing a high protein content without requiring refrigeration. This makes it an ideal ingredient for various food products, from baked goods to protein shakes.

Nutritional Composition of Egg Protein Powder

Egg protein powder is renowned for its complete amino acid profile, which includes all the essential amino acids required for muscle repair and growth. This characteristic makes it a favorite among athletes and bodybuilders. The powder also retains other vital nutrients, such as vitamins and minerals, contributing to a balanced diet. Moreover, the dehydration process does not significantly diminish its nutritional value, making it a practical and healthful alternative to fresh eggs.

Versatility in Culinary Applications

The adaptability of egg protein powder extends beyond health supplements. In baking, it serves as a leavening agent, providing structure and moisture retention in doughs and batters. In pasta production, it enhances protein content and improves texture and elasticity. Moreover, it is utilized in the nutritional supplement industry, particularly in protein powders and meal replacements, owing to its solubility and pleasant taste.

Benefits Over Fresh Eggs

Egg protein powder offers several advantages over fresh eggs. Its extended shelf life eliminates the need for refrigeration, making it more convenient for storage and transportation. This attribute is particularly beneficial for large-scale food producers and manufacturers. Additionally, the powder form reduces the risk of contamination, as the pasteurization process involved in drying acts as a sterilizing agent, ensuring food safety.

The Role of Egg Powder Spray Dryers

The egg powder spray dryer is the core of egg protein powder production. This advanced technology facilitates the efficient transformation of liquid eggs into stable, easy-to-handle powder.

The Mechanics of Spray Drying

Spray drying is a sophisticated process involving the atomization of a liquid mixture into a heated chamber. As the droplets interact with the hot air, they dry almost instantaneously, resulting in a fine powder. This process effectively preserves the egg’s nutritional content while guaranteeing a long shelf life. The rapid drying also prevents the degradation of sensitive components, maintaining the integrity of the product.

Efficiency and Homogeneity

The primary advantage of spray drying lies in its efficiency. It allows for the rapid processing of large volumes of liquid eggs, significantly reducing production time. The resulting powder is homogeneous and free-flowing, simplifying handling and packaging. The uniformity of the product ensures consistency in quality, which is essential for industrial applications.

Contamination Control and Quality Assurance

Spray drying inherently minimizes contamination risks. The high temperatures involved act as a sterilizing agent, eliminating pathogens and ensuring the safety of the final product. This aspect is critical in the food industry, where maintaining quality and safety standards is paramount. Furthermore, the controlled environment of the spray drying chamber allows for precise adjustments, ensuring that the final product meets specific quality criteria.

Where to Find Egg Powder Spray Dryers in Rio de Janeiro

A range of local options is available for businesses in Rio de Janeiro looking to invest in spray drying technology. These establishments offer not only the equipment but also the expertise required to integrate it into existing production lines.

Leading Suppliers and Manufacturers

In Rio, several companies specialize in food processing equipment, including spray dryers. These suppliers often have extensive experience and offer a range of models tailored to different production needs. They provide comprehensive consultation services to help businesses select the right equipment for their specific requirements. Additionally, many offer installation and training services, ensuring a smooth transition into using the new technology.

Equipment Rental and Leasing Options

Rental and leasing options are available for businesses that require the equipment temporarily. These services provide flexibility, allowing companies to scale their operations according to demand without a significant upfront investment. Renting also offers the opportunity to test the equipment’s capabilities before committing to a purchase, making it a cost-effective solution for many businesses.

Evaluating Providers: Key Considerations

When choosing a provider, several factors must be considered. The spray dryer’s capacity and specifications should align with the business’s production goals. Technical support and after-sales services are also crucial, as they ensure the smooth operation and maintenance of the equipment. It’s essential to verify the provider’s reputation and ensure that the equipment complies with local health and safety regulations, safeguarding both the business and its customers.

Operating an Egg Powder Spray Dryer

Operating a spray dryer requires a basic understanding of its mechanics and maintenance needs. Proper training is essential to ensure efficiency and safety.

Preparing the Egg Mixture

Preparation is a critical step in the spray drying process. The liquid egg mixture must be adequately homogenized to achieve consistent results. This involves ensuring that the mixture is free from lumps and has a uniform consistency. Proper preparation not only affects the quality of the final product but also optimizes the efficiency of the drying process.

Adjusting and Monitoring Settings

Setting up the spray dryer involves adjusting parameters such as temperature, airflow, and feed rate. These settings determine the characteristics of the powder, including particle size and moisture content. Continuous monitoring during operation is necessary to maintain optimal drying conditions. Operators must be vigilant, making adjustments as needed to ensure consistent quality.

Routine Maintenance and Troubleshooting

Regular maintenance is crucial to keep the spray dryer in good working condition. This includes cleaning the equipment to prevent residue buildup, checking for wear and tear, and replacing parts as needed. Operators should be trained in basic troubleshooting to address common issues promptly, minimizing downtime and maintaining productivity.

Ensuring Safety in Operations

Given the high temperatures involved, safety is paramount. Operators should be trained in handling the equipment and aware of emergency procedures. Proper ventilation and protective gear are also necessary to ensure a safe working environment. Implementing safety protocols minimizes risks and ensures the well-being of personnel.

The Future of Egg Powder Production

With advancements in food technology, the future of egg powder production looks promising. Innovations in spray drying technology are expected to improve efficiency, reduce energy consumption, and enhance the quality of the final product.

Embracing Sustainability in Production

Sustainability is becoming a central focus in food production. Future developments in spray drying may prioritize reducing the environmental impact by minimizing energy consumption and waste. Implementing eco-friendly practices and technologies can contribute to a more sustainable and responsible production process.

Tailoring Products to Consumer Preferences

As consumer demands become more specific, there is potential for customized egg powders with added nutrients or flavors. This trend reflects a broader movement towards personalized nutrition, where products are tailored to meet individual dietary needs and preferences. Such innovations can open new market opportunities and cater to niche consumer segments.

Advancements in Automation and Technology

Automation in spray drying could further streamline the process, reducing labor costs and increasing production speed. Advances in technology may also enhance the precision of the drying process, improving the quality and consistency of the final product. Embracing these advancements can position businesses at the forefront of the industry, offering competitive advantages in efficiency and product quality.

Conclusion

Egg powder spray dryers play a pivotal role in transforming liquid eggs into versatile, long-lasting egg protein powder. For businesses in Rio de Janeiro and beyond, understanding this technology and its applications is key to harnessing its full potential. By choosing the right equipment and maintaining high operational standards, companies can effectively meet the growing demand for egg protein powder in various industries.

As the industry continues to evolve, keeping an eye on emerging trends and technological advancements will ensure that businesses remain competitive in the market. Whether you’re a small business owner or a large-scale producer, investing in an egg powder spray dryer could be a game-changer for your operations.

Specifications

|

spec

|

ZPG-25

|

ZPG-50

|

ZPG-80

|

ZPG-100

|

ZPG-150

|

ZPG-200

|

ZPG-300

|

|

|

evaporation capacity(kg/h)

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

|

process amount of material liquid(kg/h)

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

|

output of finished pcoduct(kg/h)

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

24-42

|

36.8-56.4

|

55-85

|

|

|

solid content of material liquid( %)

|

18-30

|

|||||||

|

moisture content of finished product( %)

|

3-5

|

|||||||

|

electric power(kw)

|

63

|

132

|

153

|

204

|

246

|

330

|

||

|

heat source

|

Steam pius electricity

|

|||||||

|

Collecting method of product and its efficiency

|

Grade one or two or three stage cyclone wet dust remover is greater than or equal to 95%

|

|||||||

|

automatic control meters and instruments

|

indicator of not air and exhaust air temperature

|

|||||||

|

temperature of air inlet(℃)

|

160-220

|

|||||||

|

temperature of air outlet(℃)

|

80-100

|

|||||||

|

L

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15000

|

|

|

overal dimensions(mm)

|

W

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

H

|

6200

|

6900

|

8000

|

8900

|

10750

|

11900

|

13000

|

|

Applications

No Content Matching Your Selection Is Found.