Table of Contents

Product Detail

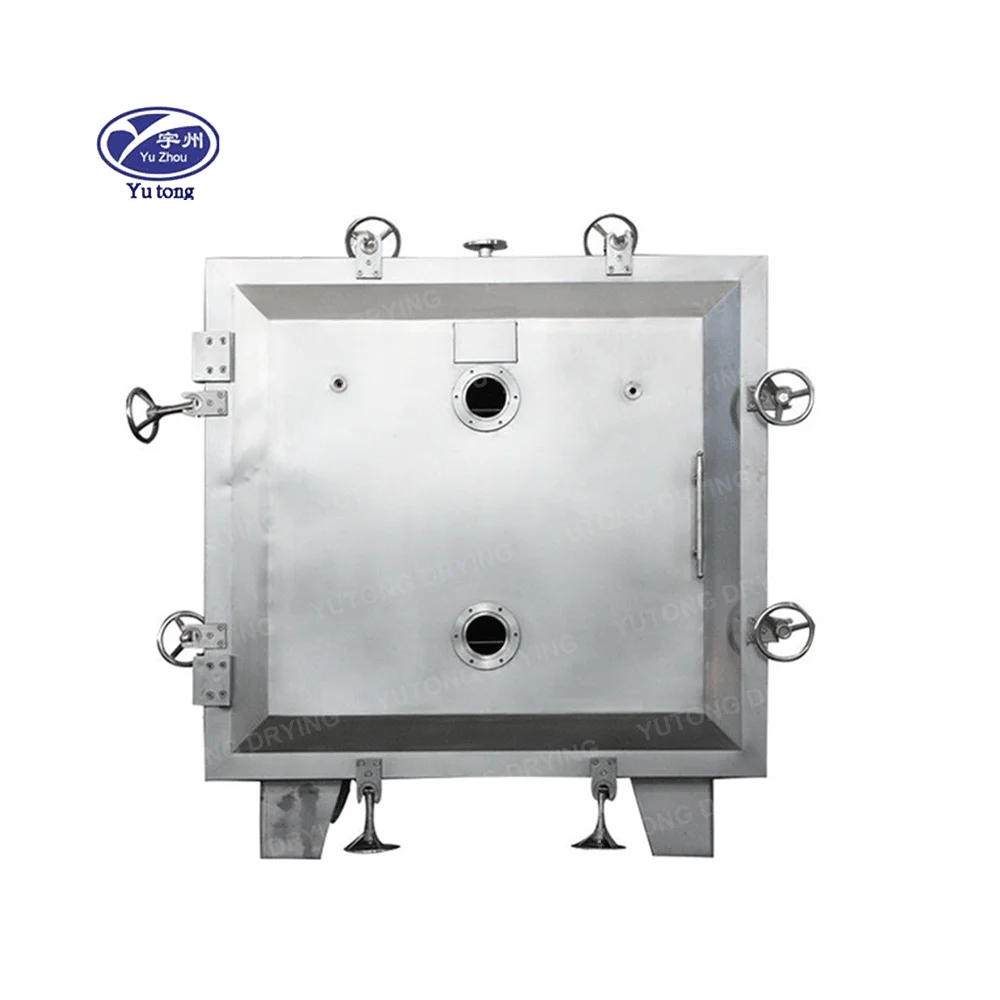

continuous vacuum dryer for sale

In the ever-evolving landscape of industrial machinery, finding the right equipment tailored to your specific drying needs can be daunting. The stakes are even higher when dealing with specialized machinery like continuous vacuum dryers. These machines play a crucial role in industries where precise moisture removal is imperative, ensuring efficiency and consistency in drying processes. Whether you’re considering the acquisition of a surplus large vacuum dryer or a pre-owned vacuum shelf dryer, having a comprehensive understanding of your options is essential to making an informed investment.

Understanding Continuous Vacuum Dryers

Continuous vacuum dryers are at the forefront of technological advancement in material drying, combining efficiency with product quality preservation.

The Science Behind Continuous Vacuum Drying

At the heart of a continuous vacuum dryer lies its ability to operate in a vacuum environment, which significantly lowers the boiling point of liquids. This scientific principle allows the drying process to occur at reduced temperatures, which is crucial for preserving the quality of heat-sensitive materials. By preventing thermal degradation, these dryers maintain the structural integrity and essential properties of various products, from delicate pharmaceuticals to nutrient-rich food items.

Benefits of Low-Temperature Drying

Operating at lower temperatures offers multiple benefits. It not only ensures that volatile compounds are retained but also minimizes the risk of oxidation, which can alter the product’s color, flavor, and efficacy. This makes continuous vacuum dryers indispensable in sectors like food processing and pharmaceuticals, where maintaining the product’s original characteristics is paramount.

Applications Across Industries

Continuous vacuum dryers’ versatility is evident in their wide-ranging applications. In the chemical industry, they dry heat-sensitive and volatile compounds. In pharmaceuticals, they ensure that active ingredients remain potent. Food industries rely on them to produce dried products that retain flavor and nutrition. This adaptability makes them a valuable asset in any industry requiring precise drying solutions.

Types of Vacuum Dryers

Vacuum dryers come in various configurations, each designed to meet specific industrial needs. Understanding the distinctions can help in selecting the right type for your operations.

Vacuum Belt Dryer

The vacuum belt dryer is renowned for its ability to handle continuous drying of substantial quantities of product. Its efficiency and consistent output quality make it a staple in the food and pharmaceutical industries. These dryers feature a conveyor belt system that transports the product through a vacuum chamber, ensuring uniform drying. The technology behind vacuum belt dryers allows for precise control over drying parameters, making them ideal for sensitive products that require gentle handling.

Innovations in Vacuum Belt Drying

Recent innovations have enhanced the functionality of vacuum belt dryers, incorporating features like automated control systems and energy recovery mechanisms. These advancements not only improve operational efficiency but also reduce energy consumption, making them more sustainable options for modern industries.

Rotary Vacuum Dryer

Rotary vacuum dryers are versatile machines designed for various materials, including pastes, granules, and powders. The rotating drum ensures even drying and can be lined with materials such as glass to prevent contamination. Their design allows for continuous mixing during the drying process, which is particularly beneficial for materials that require uniform moisture removal.

Customization and Flexibility

One of the standout features of rotary vacuum dryers is their ability to be customized to specific material characteristics. This flexibility allows industries to tailor the drying process to their unique requirements, enhancing efficiency and product quality.

Vacuum Tray Dryer

Vacuum tray dryers offer an economical solution for batch processing, handling a variety of materials efficiently. They are commonly used in industries like chemicals and pharmaceuticals, where precise control over drying conditions is critical. The design of these dryers allows for easy loading and unloading of trays, making them ideal for operations that require frequent product changes.

Cost-Effectiveness and Reliability

Used vacuum tray dryers are particularly attractive to businesses looking to optimize costs without compromising on quality. When well-maintained, these machines provide reliable performance comparable to new models, offering significant savings.

Key Considerations When Buying a Vacuum Dryer

Purchasing a continuous vacuum dryer involves careful consideration of several factors to ensure optimal investment.

Cost and Budget

The financial aspect of acquiring a vacuum dryer is multifaceted, with costs varying based on type, size, and manufacturer. A rotary vacuum dryer might present different financial implications compared to a vacuum belt dryer. Understanding your budget constraints while assessing the potential return on investment is crucial. It’s important to consider not just the upfront cost but also the long-term operational expenses, including maintenance and energy consumption.

Evaluating Total Cost of Ownership

When budgeting for a vacuum dryer, consider the total cost of ownership, which includes purchase price, installation costs, maintenance, and operational expenses. This comprehensive approach ensures a realistic assessment of the financial impact over the machine’s lifespan.

Size and Capacity

Determining the appropriate size and capacity of the dryer is essential to meet your production needs efficiently. Large-scale operations might benefit from surplus large vacuum dryers, while smaller enterprises could find smaller units more suitable. It’s essential to align the dryer’s capacity with your production volume to avoid underutilization or bottlenecks in the drying process.

Scalability and Future Growth

Consider the potential for future growth in your operations. Choosing a dryer that can be easily scaled up or modified to handle increased production demands ensures long-term viability and flexibility.

Manufacturer and Supplier Reputation

The reputation of the manufacturer or supplier is a key consideration, influencing the quality and reliability of the equipment. Chinese vacuum belt dryer manufacturers, for instance, have gained a reputation for producing cost-effective and durable machines. Conducting thorough research and reading customer reviews can provide valuable insights into the reliability and performance of different manufacturers’ products.

Assessing After-Sales Support

A reputable manufacturer should offer robust after-sales support, including technical assistance, spare parts availability, and maintenance services. This support is critical in ensuring the longevity and optimal performance of the equipment.

Benefits of Using Vacuum Dryers

Vacuum dryers present numerous advantages over traditional drying methods, making them a favored choice in diverse industries.

Energy Efficiency

The design of vacuum dryers allows for significant energy savings by reducing the boiling point of liquids. Less energy is required to dry, leading to lower operational costs. Vacuum dryers’ energy efficiency not only translates into cost savings but also aligns with sustainable business practices, reducing the overall carbon footprint.

Optimizing Energy Consumption

Modern vacuum dryers are equipped with energy-saving features such as heat recovery systems and efficient insulation. These enhancements further reduce energy consumption, making them an attractive option for environmentally conscious industries.

Preservation of Product Quality

One of the standout benefits of vacuum dryers is their ability to maintain the quality of sensitive materials. By operating at low temperatures, these dryers prevent degradation and preserve essential properties, which is crucial in industries like pharmaceuticals and food, where product integrity is critical.

Ensuring Product Stability

In addition to preserving quality, vacuum dryers help ensure the stability and shelf life of products. By effectively removing moisture, they minimize the risk of microbial growth and spoilage.

Versatility

Vacuum dryers’ versatility, including their ability to handle diverse materials, from powders and granules to pastes and liquids, underscores their suitability for various industrial applications. This adaptability provides a flexible solution for different drying needs.

Meeting Diverse Industrial Needs

Industries ranging from chemicals to food processing can benefit from vacuum dryers’ adaptability. Their ability to be tailored to specific material characteristics ensures optimal drying performance across different applications.

Used Vacuum Dryers: A Cost-Effective Option

For businesses keen on minimizing expenses, purchasing a used vacuum dryer offers a viable solution without sacrificing functionality.

Assessing the Condition

When considering a used vacuum dryer, it’s crucial to thoroughly inspect the equipment for any signs of wear, damage, or corrosion. Ensuring that all components are in working order and that the dryer has been well-maintained is essential to avoid future operational issues.

Evaluating Maintenance Records

Request maintenance records and service history from the seller. A well-documented history provides insights into the machine’s condition and any past issues that may affect performance.

Understanding Usage History

Understanding the dryer’s previous usage is important to gauge its remaining lifespan and potential performance. Machines that have been used in less demanding applications and maintained regularly are likely to offer better value and reliability.

Compatibility with Existing Systems

Ensure that the used dryer is compatible with your existing processes and infrastructure. This includes checking for any necessary modifications or adjustments to integrate the dryer seamlessly into your production line.

Benefits of Purchasing Used Equipment

Buying used equipment can offer substantial cost savings, allowing businesses to allocate resources to other areas of their operations. Additionally, well-maintained used dryers can provide performance comparable to new models.

Conclusion

Continuous vacuum dryers stand as indispensable tools across various industries, offering efficient and high-quality drying solutions. Whether you’re in the market for a new or used vacuum dryer, understanding the different types and key considerations is critical to making an informed decision. By selecting the right equipment, businesses can enhance their production processes and achieve superior results.

The range of options available, from vacuum belt dryers to rotary vacuum drum dryers and surplus large vacuum dryers, ensures that there is a solution to meet every need and budget. Taking the time to research and consult with manufacturers will lead to finding the best continuous vacuum dryer for your operations, ultimately contributing to improved productivity and product quality.

Specifications

|

Item

|

YZG-600

|

YZG-800

|

FZG-10

|

FZG-15

|

|

Dryer inside size

|

Φ600X976

|

Φ800X1320

|

1500X1040X1200

|

1500X1400X1200

|

|

Dryer outside size

|

750X950X1050

|

950X1210X1350

|

1676X1700X1564

|

1676X2060X1564

|

|

Layers of baking shelves

|

4

|

5

|

5

|

8

|

|

Layers distance

|

85

|

120100

|

120

|

120

|

|

Baking plate size

|

310x600x45

|

460X640X45

|

460X640X45

|

460X640X45

|

|

Quantity of baking plate

|

4

|

4

|

20

|

32

|

|

Work pressure inside the pipe support

|

<=0.784

|

<=0.784

|

<=0.784

|

<=0.784

|

|

Operate temperature of baking shelves

|

35-150

|

35-150

|

35-150

|

35-150

|

|

Vacuum degree in dryer

|

-0.1

|

-0.1

|

-0.1

|

-0.1

|

|

in -0.1 Mpa 110 degree,evaporation rate of water

|

7.2

|

7.2

|

7.2

|

7.2

|

|

When use condenser,the vacuum model,powder

|

2X-15A2KW

|

2X-30A3KW

|

2X-70A5.5KW

|

2X-70A5.5KW

|

|

Without condenser,vacuum pump model and power

|

SK-0.51.5KW

|

SK-12.2KW

|

SK-24KW

|

SK-25.5KW

|

|

Weight

|

250

|

600

|

1400

|

2100

|

Applications

Applicable Industries:

Machinery Repair Shops, Food & Beverage Factory, Farms, Retail, Food Shop, Food & Beverage Shops