Table of Contents

Product Detail

china vacuum dryer manufacturers

In the dynamic world of industrial drying solutions, China stands out as a leading hub for vacuum dryer manufacturing. From pharmaceuticals to food processing, vacuum dryers play a crucial role in ensuring the efficiency and quality of drying processes. This article delves into the various types of vacuum dryers produced by Chinese manufacturers, highlighting their applications, benefits, and the key players in the industry.

Understanding Vacuum Dryers

Vacuum dryers are pivotal in industries where moisture removal is essential without exposing the product to high temperatures. The vacuum environment reduces the boiling point of liquids, allowing drying to occur at lower temperatures. This is particularly beneficial for heat-sensitive materials.

The Science Behind Vacuum Drying

Vacuum drying operates by reducing the atmospheric pressure around the product. This reduction in pressure lowers the boiling point of water, which means that moisture can be evaporated at much lower temperatures than usual. This process is especially advantageous for products that would degrade or lose efficacy when exposed to high temperatures. The reduced temperature requirement not only preserves the quality of the product but also enhances energy efficiency.

Benefits of Vacuum Drying

The benefits of vacuum drying extend beyond preserving product integrity. It also accelerates the drying process, which can lead to significant time and energy savings. Moreover, by minimizing thermal exposure, vacuum drying can prevent the oxidation of sensitive compounds, thus maintaining their potency and effectiveness. This makes vacuum dryers ideal for industries that prioritize quality and efficiency.

Applications of Vacuum Dryers

Vacuum dryers are used in many sectors. They are used in the pharmaceutical industry to dry heat-sensitive compounds and active ingredients. They are also utilized in the food processing industry to preserve the nutritional content and flavor of dehydrated products. In the chemical sector, vacuum dryers are essential for drying solvents and reactants, ensuring product purity and stability. Each application underscores the versatility and necessity of vacuum dryers in modern industrial processes.

Types of Vacuum Dryers Manufactured in China

China boasts a wide array of vacuum dryers, each designed to meet specific industrial needs. Here’s a breakdown of the prominent types:

1. China Vacuum Tray Dryer

The vacuum tray dryer is a staple in the pharmaceutical and chemical industries. It consists of a series of trays arranged in a cabinet where the product is placed for drying. The vacuum ensures efficient moisture removal while preserving product integrity.

Design and Functionality

The vacuum tray dryer’s design involves multiple trays that can accommodate various products simultaneously. This multi-tiered structure allows for uniform drying, as each tray is exposed to the same vacuum conditions. The enclosed cabinet design minimizes contamination risks and ensures that the drying process is conducted in a controlled environment.

Industry Applications

Vacuum tray dryers are heavily utilized in industries where maintaining the quality of the end product is paramount. They are commonly used in the production of pharmaceuticals, where precise drying conditions are required to maintain the stability of active ingredients. The chemical industry also benefits from their use, especially when drying substances that are sensitive to heat.

Advantages Over Conventional Dryers

Compared to traditional drying methods, vacuum tray dryers offer several distinct advantages. They consume less energy due to lower temperature requirements, leading to reduced operational costs. Moreover, the risk of contamination is minimal due to the sealed environment, and the uniform drying process ensures consistent product quality across all batches.

2. China Round Vacuum Dryer

Round vacuum dryers are known for their compact design and versatility. They are commonly used in smaller-scale operations or laboratories.

Compact and Efficient

Round vacuum dryers are designed for spaces where room is limited, making them ideal for small-scale operations. Their compact design does not compromise performance, and they can efficiently process smaller batches without sacrificing drying quality. This makes them particularly suitable for laboratories and research facilities.

Versatile Applications

These dryers are versatile enough to handle a variety of products, from pharmaceuticals to specialty chemicals. Their adaptability allows them to be used for experimental drying processes, making them indispensable in R&D settings where trial and error are standard.

Cost-Effective Solutions

The cost-effectiveness of round vacuum dryers is a significant advantage for smaller operations or startups. They offer a lower initial investment compared to larger systems while still providing efficient and reliable drying capabilities. Their ease of operation further enhances their appeal for businesses looking to optimize their drying processes without extensive financial outlay.

3. Vacuum Tumble Dryer China

The vacuum tumble dryer is designed for bulk processing. It rotates the material, ensuring even drying throughout the batch.

Bulk Processing Capabilities

Vacuum tumble dryers are engineered to process large quantities of material in a single batch. Their rotating mechanism ensures that each part of the material is exposed to the vacuum environment, promoting uniform drying throughout the batch. This makes them ideal for industries that deal with high-volume production.

Operational Efficiency

The operational efficiency of vacuum tumble dryers is notable, as they significantly reduce drying times compared to static systems. The tumbling action not only facilitates even drying but also prevents the formation of clumps, ensuring a consistent product texture and quality. This efficiency translates to higher throughput and reduced downtime.

Industry Relevance

These dryers are particularly relevant in the food processing and chemical industries, where bulk drying is a common requirement. They are used to dry a variety of products, from powdered chemicals to dehydrated food items, maintaining quality while achieving large-scale production goals.

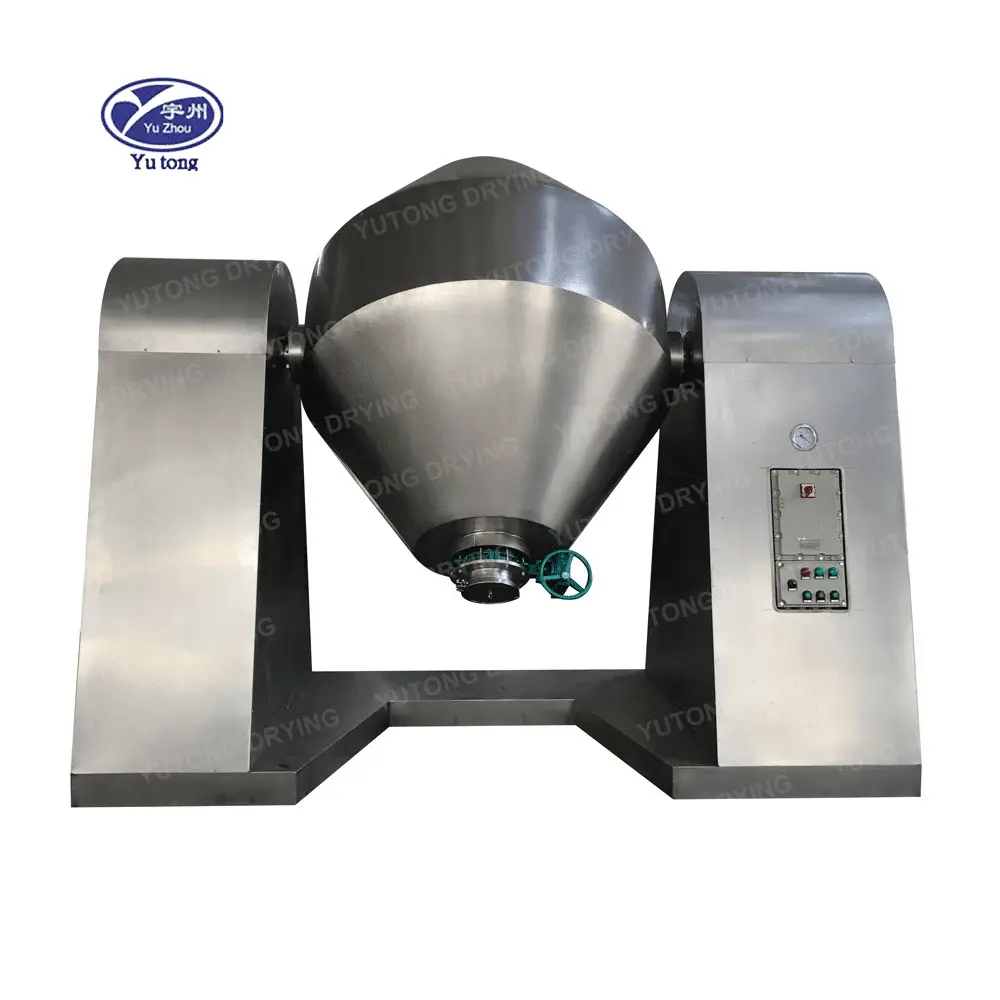

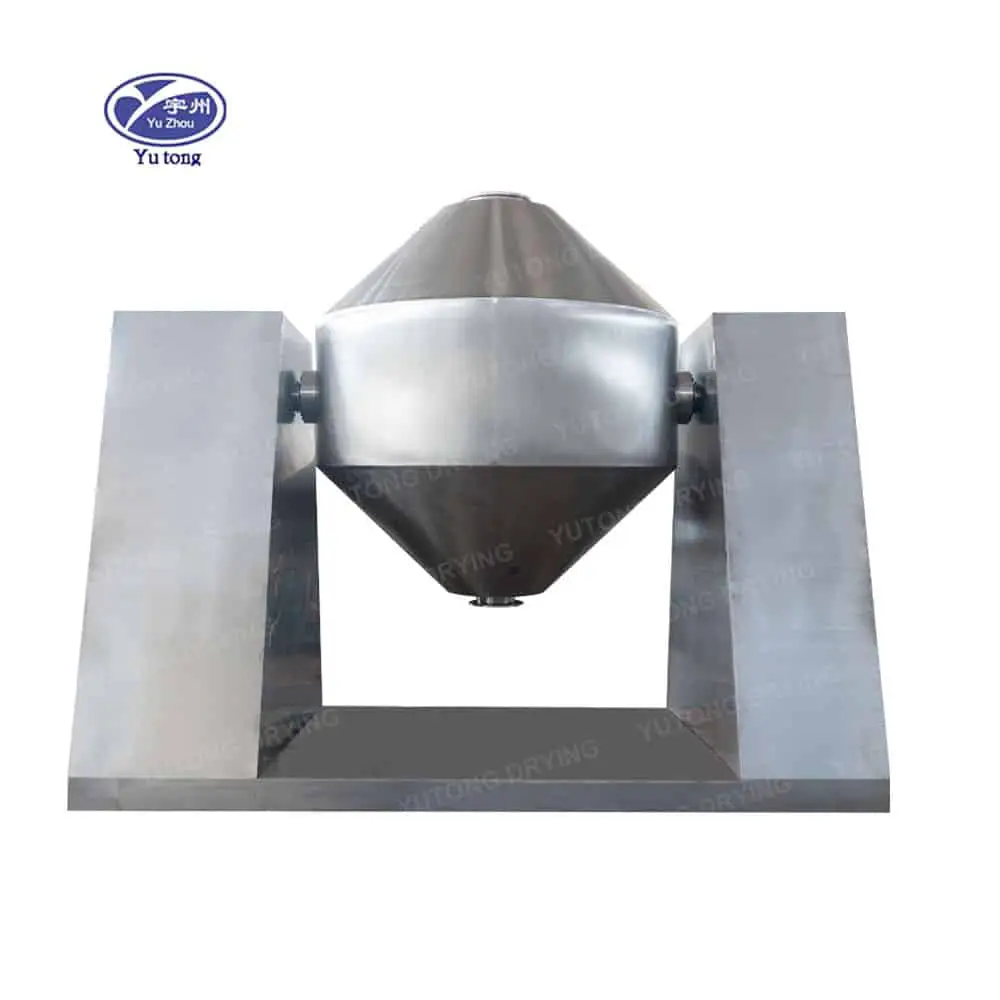

4. China Double Rotary Cone Vacuum Dryer

The double rotary cone vacuum dryer is engineered for sensitive materials that require gentle drying. Its dual-cone design enhances mixing and drying efficiency.

Innovative Design

The innovative dual-cone design of these dryers allows for thorough mixing and drying. The rotating cones ensure that the material is constantly in motion, which facilitates even heat distribution and prevents localized overheating. This design is particularly beneficial for drying sensitive materials that might degrade under harsher conditions.

Applications in Sensitive Industries

Double rotary cone vacuum dryers are widely used in industries where product sensitivity is a concern. Pharmaceuticals and fine chemicals are typical applications, as these sectors require gentle drying to maintain the integrity of the compounds. The design ensures that the drying process does not compromise the quality of these sensitive materials.

Efficiency and Product Quality

The double rotary cone vacuum dryer’s efficiency lies in its ability to deliver consistent results while maintaining high product quality. Its gentle drying action minimizes thermal degradation, making it suitable for delicate materials that require careful handling. This efficiency translates to improved product outcomes and reduced waste.

5. China Square Vacuum Dryer

Square vacuum dryers are versatile machines used in various industries. Their design allows for more considerable batch processing compared to round dryers.

Design Advantages

The square design of these dryers provides a larger surface area for drying, which allows for processing larger batches. This design is advantageous for industries that require high-capacity drying solutions without compromising on quality. The square configuration also facilitates more effortless loading and unloading of materials.

Industry Versatility

Square vacuum dryers are used across a range of industries, from pharmaceuticals to food processing. Their large capacity makes them suitable for operations that require processing significant volumes of material in a single cycle. This versatility is a key factor in their widespread adoption.

Robust and Reliable

The robust construction of square vacuum dryers ensures reliable performance even under demanding conditions. Their durability makes them a long-term investment for companies looking to enhance their drying processes. The combination of capacity and reliability makes them an ideal choice for industries that prioritize efficiency and productivity.

6. China Lab Vacuum Dryer

Lab vacuum dryers are essential in research and development. They allow for precise control over drying conditions, making them perfect for experimental studies.

Precision in Drying

Lab vacuum dryers offer unparalleled precision in controlling drying conditions. This is crucial in research and development settings, where exact parameters must be maintained to achieve consistent and reproducible results. The ability to fine-tune temperature and pressure settings makes these dryers invaluable for experimental work.

Flexibility in Research

The flexibility offered by lab vacuum dryers is a significant advantage in research environments. They can be used to test a wide range of materials and drying methods, enabling researchers to explore new processes and refine existing ones. This adaptability is essential for innovation and development in various scientific fields.

Supporting Innovation

Lab vacuum dryers play a pivotal role in supporting innovation across industries. By providing the tools necessary for precise experimentation, they enable researchers to push the boundaries of what is possible in product development. This support is critical in industries such as pharmaceuticals, where new formulations and compounds are constantly being explored.

Key Players in the Chinese Vacuum Dryer Manufacturing Sector

China is home to numerous manufacturers specializing in vacuum dryers. These companies are known for their innovation, quality, and competitive pricing.

Leading Manufacturers

- Changzhou Yibu Drying Equipment Co., Ltd.: Renowned for its extensive range of vacuum dryers, Yibu is a leader in innovation and quality. Their commitment to research and development has positioned them at the forefront of the industry, offering cutting-edge drying solutions to a global market.

- Changzhou Fanqun Drying Equipment Co., Ltd.: Specializes in industrial vacuum drying solutions with a focus on energy efficiency and high performance. Fanqun’s emphasis on sustainable practices and energy-saving technology has made them a preferred choice for environmentally conscious businesses.

- Changzhou Suli Drying Equipment Co., Ltd.: Known for its robust and versatile vacuum dryers, catering to a wide range of industries. Suli’s dedication to providing tailored solutions has earned them a reputation for reliability and customer satisfaction.

Innovations and Contributions

These leading manufacturers are not just equipment providers; they are innovators contributing to the advancement of drying technology. Their focus on integrating innovative technologies and automation has set new benchmarks in efficiency and performance. By continuously investing in R&D, they ensure that their products remain at the cutting edge of the industry.

Global Reach and Influence

Chinese vacuum dryer manufacturers have successfully expanded their reach beyond domestic markets. Their competitive pricing and high-quality products have made them attractive options for international buyers. As a result, they have established a strong global presence, influencing drying technology standards worldwide.

Benefits of Choosing Chinese Vacuum Dryer Manufacturers

Cost-Effectiveness

Chinese manufacturers offer competitive pricing without compromising on quality. This affordability makes them attractive to global buyers.

Economic Advantages

The economic advantage of choosing Chinese manufacturers lies in their ability to produce high-quality vacuum dryers at a fraction of the cost compared to other markets. This cost-effectiveness is a result of efficient production processes and economies of scale. For businesses, this translates to significant savings without sacrificing product quality.

Competitive Edge

By offering cost-effective solutions, Chinese manufacturers provide businesses with a competitive edge. Lower equipment costs mean reduced overheads, allowing companies to allocate resources to other critical areas such as research, development, and marketing. This financial flexibility is crucial for staying competitive in fast-paced industries.

Appeal to Global Markets

The affordability of Chinese vacuum dryers has led to their widespread adoption in global markets. Businesses worldwide are drawn to the promise of high-quality equipment at competitive prices, making Chinese manufacturers key players in the international arena.

Innovation and Technology

The integration of advanced technology and innovation in design is a hallmark of Chinese vacuum dryers, ensuring high efficiency and reliability.

Cutting-Edge Technology

Chinese manufacturers are at the forefront of incorporating cutting-edge technology into their vacuum dryers. This includes smart features such as automated controls, data analytics, and IoT integration, which enhance the equipment’s functionality and efficiency. These innovations ensure that Chinese dryers meet the evolving needs of modern industries.

Continuous Improvement

A commitment to continuous improvement drives Chinese manufacturers to push the boundaries of what vacuum dryers can achieve. By staying abreast of technological advancements, they can offer solutions that are not only efficient but also adaptable to future challenges. This proactive approach keeps them ahead of the competition.

Reliability and Performance

The focus on innovation and technology translates to highly reliable and performant vacuum dryers. Businesses can depend on these machines to deliver consistent results, minimize downtime, and maximize productivity. This reliability is a key factor in the widespread trust and preference for Chinese-manufactured vacuum dryers.

Customization

Chinese manufacturers offer a high degree of customization to meet specific industry requirements, providing tailored solutions for diverse applications.

Tailored Solutions

Customization is a core strength of Chinese vacuum dryer manufacturers. They can tailor equipment to the specific needs of each client, whether by modifying existing designs or creating entirely new solutions. This flexibility ensures that businesses receive equipment that perfectly aligns with their operational requirements.

Meeting Diverse Needs

The capacity to customize extends across various industries and applications. Whether a business requires a dryer with unique specifications for pharmaceutical production or a model suited for food processing, Chinese manufacturers can accommodate these needs. This adaptability is crucial for industries with niche demands.

Enhancing Customer Satisfaction

Providing customized solutions enhances customer satisfaction by ensuring that each client receives equipment that meets their exact specifications. This personalized approach fosters strong relationships between manufacturers and customers, leading to long-term partnerships and repeat business.

Selecting the Right Vacuum Dryer

When choosing a vacuum dryer, factors such as the nature of the material, batch size, and required drying time must be considered. Understanding these parameters helps in selecting the most suitable dryer type and manufacturer.

Considerations for Selection

- Material Compatibility: Ensure the dryer material is compatible with the product to avoid contamination and degradation. It is essential to choose a dryer constructed from materials that will not react adversely with the product being dried, ensuring product safety and quality.

- Capacity Requirements: Choose a dryer that can handle the desired batch size efficiently. Assessing the production scale and selecting a dryer with the appropriate capacity will prevent bottlenecks and optimize throughput.

- Energy Efficiency: Opt for energy-efficient models to reduce operational costs. Energy-efficient dryers not only lower utility bills but also contribute to sustainability efforts, making them a smart choice for environmentally conscious businesses.

Evaluating Manufacturer Capabilities

When selecting a manufacturer, consider their track record and reputation in the industry. Look for manufacturers with a history of delivering reliable, high-quality equipment and those who offer comprehensive after-sales support. This evaluation ensures that you partner with a company that can meet your current and future needs.

Long-Term Considerations

Selecting the right vacuum dryer also involves considering long-term operational goals. Assess whether the equipment can accommodate future growth or changes in production processes. Choosing a versatile and adaptable dryer will provide flexibility and ensure that the investment remains valuable over time.

Future Trends in Vacuum Dryer Technology

As industries evolve, so do the technologies employed in vacuum drying. Future trends point towards increased automation, innovative technology integration, and sustainability. Chinese manufacturers are at the forefront of these innovations, leading the charge in developing eco-friendly and technologically advanced drying solutions.

Automation and Smart Technology

The future of vacuum drying lies in automation and the integration of innovative technologies. Automated systems will streamline operations, reducing the need for manual intervention and minimizing human error. Innovative technology will enable real-time monitoring and data analytics, providing insights that can be used to optimize the drying process and improve efficiency.

Sustainability and Eco-Friendliness

Sustainability is becoming a significant focus for vacuum dryer manufacturers. Future developments will likely include eco-friendly designs that minimize environmental impact. This includes energy-efficient models that reduce carbon footprints and innovations that promote the use of sustainable materials in the construction of drying equipment.

Industry-Specific Innovations

Future trends will also see vacuum dryer technology tailored to meet the specific needs of different industries. This could involve the development of specialized models that cater to the unique challenges faced by sectors such as pharmaceuticals, food processing, and chemicals. By focusing on industry-specific innovations, manufacturers will continue to provide valuable solutions that meet the demands of modern production environments.

Conclusion

The landscape of vacuum dryer manufacturing in China is vast and varied, offering solutions for every industrial need. Whether you’re in pharmaceuticals, food processing, or chemical production, Chinese vacuum dryers provide reliable, efficient, and cost-effective drying solutions. By understanding the types of dryers available and the leading manufacturers, you can make informed decisions to meet your production needs.

China’s commitment to innovation and quality ensures that its vacuum dryers remain a preferred choice for industries worldwide. As the demand for efficient drying solutions grows, Chinese manufacturers are poised to continue their leadership in this critical sector. With their focus on technological advancement and customer satisfaction, they are set to shape the future of vacuum drying technology.

Specifications

|

Model

|

100

|

500

|

1000

|

1500

|

2000

|

5000

|

|

Volume (L)

|

100

|

500

|

1000

|

15000

|

2000

|

5000

|

|

Maximum Loading Volume (L)

|

40

|

200

|

400

|

600

|

800

|

2000

|

|

Maximum Loading Capacity (kg)

|

20

|

100

|

200

|

300

|

400

|

1000

|

|

Rotating Speed (rpm)

|

3~13

|

6

|

5

|

4

|

||

|

Motor Power (k w)

|

0.75

|

1.5

|

3

|

4

|

5.5

|

15

|

|

Floor Area (mm)

|

2160 × 800

|

2350× 800

|

2860 × 1300

|

3060 × 1300

|

3260 × 1400

|

4400 × 2500

|

|

Rotation Height (mm)

|

1750

|

2250

|

2800

|

2940

|

2990

|

4200

|

|

Design Pressure In Container (MPa)

|

-0.09 to 0.096

|

|||||

|

Interlayer Design Pressure (MPa)

|

≤ 0.3

|

|||||

|

Weight (kg)

|

800

|

1200

|

2800

|

3300

|

3600

|

8600

|

Applications

Applicable Industries: Machinery Repair Shops, Food & Beverage Factory, Farms, Retail, Food Shop, Energy & Mining, Food & Beverage Shops