Table of Contents

Product Detail

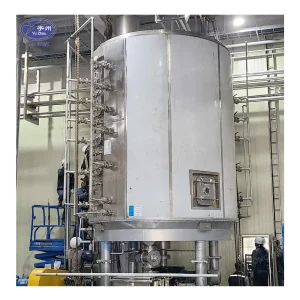

china vacuum disc dryer

As industries continue to seek efficient and cost-effective drying solutions, the vacuum disc dryer has emerged as a favored choice. Specifically, the China vacuum disc dryer stands out due to its advanced technology and competitive pricing. In this article, we’ll delve into the mechanics of vacuum disc dryers, explore the benefits they offer, and shed light on why sourcing from a vacuum disc dryer factory in China could be a wise decision for your business.

Understanding Vacuum Disc Dryers

In the complex realm of industrial drying, vacuum disc dryers play a pivotal role. Understanding their mechanics and functionality is essential for businesses considering their integration into their production processes.

What is a Vacuum Disc Dryer?

A vacuum disc dryer is a piece of industrial equipment used primarily for drying materials with high moisture content. It operates under low-pressure conditions, which significantly reduces the boiling point of the liquid within the materials. This makes the drying process faster and more energy-efficient, which is crucial for industries aiming to optimize production costs and time. The design of the vacuum disc dryer maximizes the surface area for heat transfer, allowing materials to dry evenly and thoroughly.

Key Components and Structure

The vacuum disc dryer consists of several key components that make it effective. A series of discs are mounted on a rotating shaft within a sealed chamber. These discs are heated internally by steam or another heating medium. The chamber is designed to maintain a vacuum, which is essential for lowering the boiling point of the moisture in the materials. The rotating shaft ensures that all material surfaces are exposed to the heat source, promoting uniform drying.

How Does It Work?

The operation of a vacuum disc dryer is both simple and highly effective. As the discs rotate, the material to be dried is spread thinly over their surface, enabling efficient heat transfer and rapid drying. The vacuum environment helps in lowering the drying temperature, making it suitable for heat-sensitive materials. This method allows for significant energy savings, as less heat is required to achieve the desired drying effect. Additionally, the controlled environment prevents oxidation and other chemical changes in sensitive materials.

Applications in Various Industries

Vacuum disc dryers are not limited to a single industry; they are versatile tools used across various sectors. In the pharmaceutical industry, they ensure the stability of heat-sensitive compounds. The food industry maintains the integrity and quality of food products by preventing nutrient loss. The chemical industry benefits from their precision in drying complex chemical compounds without altering their composition. This versatility makes vacuum disc dryers a valuable asset in many production lines.

Advantages of Using Vacuum Disc Dryers

Their numerous advantages drive the adoption of vacuum disc dryers in industrial processes. These dryers offer benefits that extend beyond mere drying efficiency, impacting overall production capabilities.

Energy Efficiency

One of the primary advantages of a vacuum disc dryer is its energy efficiency. By utilizing a vacuum to lower the boiling point, less heat is required to evaporate the moisture from the materials. This results in significant energy savings compared to traditional drying methods. The reduction in energy consumption not only lowers operational costs but also contributes to environmental sustainability. Companies can achieve their production goals while minimizing their carbon footprint.

Versatility Across Sectors

Vacuum disc dryers are versatile and can be used in a variety of industries, including pharmaceuticals, chemicals, food processing, and more. Their ability to handle heat-sensitive materials without degrading their quality makes them an excellent choice for industries that demand high standards. This versatility ensures that companies can use a single piece of equipment for multiple applications, streamlining production processes and reducing the need for numerous machines.

Consistent Quality and Precision

The controlled environment within a vacuum disc dryer ensures that the drying process is uniform. This consistency in drying leads to a high-quality end product, which is crucial for maintaining standards, especially in the pharmaceutical and food industries. The precision of vacuum disc dryers means that businesses can maintain strict quality control measures, ensuring that every batch meets the required specifications. This reliability is essential for companies that operate in highly regulated industries.

Reduced Processing Time

Vacuum disc dryers significantly reduce the time required for drying processes. The efficient heat transfer and lower boiling point allow materials to dry faster than with conventional methods. This reduction in processing time translates to increased productivity, allowing companies to meet tight deadlines and increase their output. Faster processing times also mean that companies can respond more quickly to market demands, giving them a competitive edge.

Why Choose a Vacuum Disc Dryer from China?

China has established itself as a leader in manufacturing industrial equipment, including vacuum disc dryers. There are compelling reasons to consider sourcing these machines from Chinese manufacturers.

Cost-Effectiveness and Economic Benefits

China is known for offering competitive pricing on industrial equipment without compromising on quality. This cost-effectiveness is a result of efficient manufacturing processes and economies of scale, which benefit businesses looking to reduce capital expenditure. By purchasing from China, companies can allocate resources to other critical areas of their operations, enhancing overall efficiency and growth potential.

Advanced Technology and Innovation

Chinese manufacturers have invested heavily in research and development, ensuring that their vacuum disc dryers are equipped with the latest technology. This means you can expect high performance and efficiency from a China vacuum disc dryer. Innovations in design and functionality are constantly being integrated into new models, providing businesses with cutting-edge tools for their production needs. This commitment to technology ensures that Chinese vacuum disc dryers remain at the forefront of the industry.

Reliable Supply Chain and Support

With a well-established supply chain network, sourcing a vacuum disc dryer from China ensures timely delivery and support. This is particularly beneficial for businesses that require quick turnarounds and reliable after-sales service. The robust supply chain also means that parts and maintenance services are readily available, minimizing downtime and ensuring continuous production. Chinese manufacturers often offer comprehensive support packages, including installation and troubleshooting services.

Commitment to Quality Standards

Chinese manufacturers adhere to stringent quality standards, ensuring that their products meet international benchmarks. This commitment to quality is evident in the durability and performance of their vacuum disc dryers. By sourcing from China, businesses can be assured of receiving equipment that is not only cost-effective but also reliable and long-lasting. The adherence to global standards means that Chinese vacuum disc dryers are suitable for use in any international market.

Selecting the Right Vacuum Disc Dryer Factory

When looking to purchase a vacuum disc dryer from China, selecting the right factory is crucial. Here are some factors to consider when making an informed decision.

Reputation and Experience

Choose a factory with a strong reputation and extensive experience in manufacturing vacuum disc dryers. A well-established factory is likely to have a track record of delivering high-quality products and services. Researching customer reviews and testimonials can provide valuable insights into a manufacturer’s reliability and product performance. An experienced manufacturer will also have the expertise to offer advice and solutions tailored to your specific needs.

Customization Options for Specific Needs

Industries have specific needs, and a one-size-fits-all approach may not work. Look for a factory that offers customization options to tailor the vacuum disc dryer to your precise requirements. Customization ensures that the equipment aligns perfectly with your production processes, maximizing efficiency and effectiveness. A manufacturer that offers flexible design options demonstrates a commitment to meeting the unique demands of their clients.

Quality Assurance and Certifications

Ensure that the factory follows stringent quality assurance processes. This includes adherence to international standards and certifications, which guarantee that the equipment is safe and reliable. Certifications such as ISO and CE are indicators of a manufacturer’s commitment to quality. By choosing a factory with these credentials, businesses can be confident in the safety and efficacy of their vacuum disc dryers.

After-Sales Support and Service

After-sales support is crucial for maintaining the longevity and performance of your vacuum disc dryer. Select a factory that offers comprehensive support services, including installation, maintenance, and troubleshooting. Reliable after-sales service ensures that any issues are promptly addressed, minimizing downtime and ensuring continuous operation. A manufacturer with a dedicated support team can provide peace of mind and a smooth operational experience.

Conclusion

The China vacuum disc dryer is an excellent choice for industries seeking efficient and reliable drying solutions. With its energy efficiency, versatility, and consistent quality, it stands out as a valuable addition to any production line. By sourcing from a reputable vacuum disc dryer factory in China, businesses can enjoy cost savings, advanced technology, and robust support.

Before making a purchase, take the time to research and select a factory that aligns with your specific needs. With the right partner, a vacuum disc dryer can significantly enhance your production process and contribute to your business’s success. The investment in a high-quality vacuum disc dryer from China can lead to increased productivity, reduced costs, and a stronger competitive position in the market.

Specifications

|

Specifications

|

Outer Diameter (mm)

|

Height (mm)

|

Drying Area (m2)

|

Power (kw)

|

|

1200/4

|

1850

|

2608

|

3.3

|

1.1

|

|

1200/6

|

3028

|

4.9

|

||

|

1200/8

|

3448

|

6.6

|

1.5

|

|

|

1200/10

|

3868

|

8.2

|

||

|

1200/12

|

4288

|

9.9

|

||

|

1500/6

|

2100

|

3022

|

8.0

|

2.2

|

|

1500/8

|

3442

|

10.7

|

||

|

1500/10

|

3862

|

13.4

|

||

|

1500/12

|

4282

|

16.1

|

3.0

|

|

|

1500/14

|

4702

|

18.8

|

||

|

1500/16

|

5122

|

21.5

|

||

|

2200/6

|

2900

|

3262

|

18.5

|

3.0

|

|

2200/8

|

3682

|

24.6

|

||

|

2200/10

|

4102

|

30.8

|

||

|

2200/12

|

4522

|

36.9

|

4.0

|

|

|

2200/14

|

4942

|

43.1

|

5.0

|

|

|

2200/16

|

5362

|

49.3

|

||

|

2200/8

|

2900

|

5782

|

55.4

|

5.5

|

|

2200/20

|

6202

|

61.6

|

||

|

2200/22

|

6622

|

67.6

|

7.5

|

|

|

2200/24

|

7042

|

73.9

|

||

|

2200/26

|

7462

|

80.0

|

||

|

3000/8

|

3800

|

4050

|

48.0

|

11.0

|

|

3000/10

|

4650

|

60.0

|

||

|

3000/12

|

5250

|

72.0

|

||

|

3000/14

|

5850

|

84.0

|

||

|

3000/16

|

6450

|

96.0

|

||

|

3000/18

|

7050

|

108.0

|

13.0

|

|

|

3000/20

|

7650

|

120.0

|

||

|

3000/22

|

8250

|

132.0

|

||

|

3000/24

|

8850

|

144.0

|

||

|

3000/26

|

9450

|

156.0

|

15.0

|

|

|

3000/28

|

10050

|

168.0

|

||

|

3000/30

|

10650

|

180.0

|

Applications

PLG continuous plate dryer is appropriate for drying, calcining, pyrolysis, cooling, reaction and sublimation in the chemical, pesticide, food and agricultural industries. This drying machine is mainly used in the following fields:

1. Organic chemical products: resin, melamine, aniline, stearate, calcium formate and other organic chemical material and

intermediate

2. Inorganic chemical products: calcium carbonate, magnesium carbonate, white carbon black, sodium chloride, cryolite, various

sulfate and hydroxide

3. Food: cephalosporin, vitamin, salt, aluminium hydroxide, tea, ginkgo leaf and starch

4. Fodder and fertilizer: biological potash fertilizer, protein feed, grain, seed, herbicide and cellulose