Table of Contents

Product Detail

1-Description

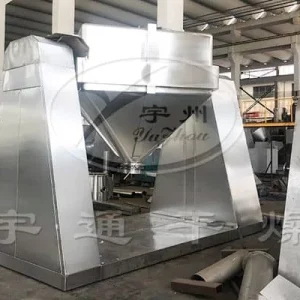

The contact part with material of CH series tough type blender machine is made of stainless steel. The gap between the blade and inner wall is slim and there is no hidden corner during mixing. The stirring axis is fixed with sealing on both ends which can prevent material leaking outside. The hopper is controlled by buttons, and its discharging is convenient.

2-Application

CH series trough type blender machine is used for blending powder or wet material to make the different ratio of materials mixed evenly, it is widely applied to mix material in industry, foodstuff industry, chemical industry, electronic industry and so on. It is especially suitable for the condition that the materials have big proportion difference and the needed uniformity is high.

1-CH series trough type blender machine has the features of compact structure, simple operation, nice appearance, small occupied place, easy cleaning and great mixing etc.

2-The blender set makes S shape stirring blade rotate though mechanical drive to force the material stir to-and-fro thus makes the blending even. The operation is controlled by electric controller, and the mixing time can be set according needs, when it reaches the set value, it will stop automatically.

Specifications

| Type | Total(m³) | Feed amount(kg) | Overall dimension(mm) | stirring speed(rpm) | power for mixing(kw) | Power for discharge (kw) |

| 150 | 0.15 | 30 | 1480×1190×600 | 24 | 3 | 0.55 |

| 200 | 0.2 | 40 | 1480×1200×600 | 24 | 4 | 0.55 |

| 300 | 0.3 | 60 | 1820×1240×680 | 24 | 4 | 1.5 |

| 500 | 0.5 | 120 | 2000×1240×720 | 20 | 5.5 | 2.2 |

| 750 | 0.75 | 150 | 2300×1260×800 | 19 | 7.5 | 2.2 |

| 1000 | 1 | 270 | 2500×1300×860 | 19 | 7.5 | 3 |

| 1500 | 1.5 | 400 | 2600×1400×940 | 14 | 11 | 3 |

| 2000 | 2 | 550 | 3000×1500×1160 | 12 | 11 | 4 |

| 2500 | 2.5 | 630 | 3500×1620×1250 | 12 | 15 | 5.5 |

| 3000 | 3 | 750 | 3800×1780×1500 | 10 | 18.5 | 5.5 |

Applications

Applicable Industries: Food & Beverage Factory, Food Shop, Food & Beverage Shops