While vacuum drying and freeze drying share some similarities, they are distinct processes with their own unique characteristics and applications.

Vacuum drying involves subjecting a material to a reduced pressure environment to lower the boiling point of water and accelerate the removal of moisture. The material is typically heated to a moderate temperature to enhance the drying process. This method is suitable for a wide range of materials and can be used in various industries such as pharmaceuticals, food, and chemicals.

On the other hand, freeze drying, also known as lyophilization, is a more complex process that involves freezing the material and then subliming the ice directly from the solid state to the gaseous state under vacuum. This process occurs at very low temperatures and pressures. Freeze drying is particularly useful for heat-sensitive materials that may be damaged by heat or exposure to oxygen.

One of the main differences between vacuum drying and freeze drying is the temperature at which the drying occurs. Vacuum drying typically operates at temperatures above freezing, while freeze drying takes place at extremely low temperatures. This difference in temperature can have a significant impact on the quality of the dried product. For heat-sensitive materials, freeze drying is often preferred as it minimizes the risk of thermal degradation.

Another difference lies in the mechanism of moisture removal. In vacuum drying, moisture is removed by evaporation, where the liquid water is converted to vapor and then removed from the system. In freeze drying, the moisture is removed by sublimation, where the ice crystals in the frozen material directly turn into vapor without passing through the liquid phase. This sublimation process can result in a product with a porous structure, which can be beneficial for certain applications such as pharmaceuticals and food products that need to rehydrate quickly.

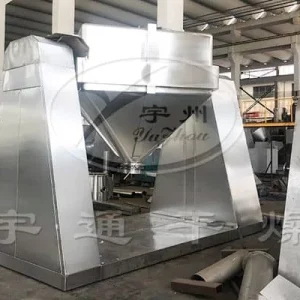

The equipment used for vacuum drying and freeze drying also differs. Vacuum drying systems usually consist of a vacuum chamber, a heating source, and a means of circulating the drying medium. Freeze drying systems, on the other hand, are more complex and typically include a freeze chamber, a vacuum pump, a condenser to collect the sublimated water vapor, and a heating system to provide the necessary energy for sublimation.

In terms of applications, both vacuum drying and freeze drying are used in industries where product quality and stability are crucial. For example, in the pharmaceutical industry, both methods can be used to dry drugs and biological products. However, freeze drying is often preferred for delicate proteins and vaccines as it can preserve their activity and stability better than vacuum drying. In the food industry, freeze drying is commonly used for drying fruits, vegetables, and meats to retain their flavor, color, and nutritional value. Vacuum drying can also be used for certain food products, but it may not provide the same level of quality preservation as freeze drying.

For instance, consider a pharmaceutical company producing a new drug. If the drug is heat-sensitive, freeze drying may be the preferred method as it can ensure that the drug’s activity is not compromised during the drying process. However, if the drug is less sensitive to heat and cost is a factor, vacuum drying may be a viable option as it is generally less expensive and faster than freeze drying.

In conclusion, vacuum drying and freeze drying are not the same. While they both involve the use of vacuum to remove moisture, they differ in terms of temperature, mechanism of moisture removal, equipment, and applications. Understanding these differences is important for choosing the most appropriate drying method for a particular material or product.