Vacuum drying stands as a sophisticated and highly efficient method of removing moisture or solvents from materials, offering significant advantages over conventional drying techniques. Its efficiency is multifaceted, encompassing aspects such as energy consumption, speed, product quality preservation, and solvent recovery. In this comprehensive article, we will explore the efficiency of vacuum drying in detail, discussing the principles that contribute to its effectiveness, its advantages in specific applications, and the factors that influence its overall performance.

Principles of Vacuum Drying Efficiency

Vacuum drying operates on the principle that lowering the pressure around a substance decreases its boiling point. Under normal atmospheric conditions, water boils at 100°C. However, under a vacuum, water can boil and evaporate at much lower temperatures. This reduction in boiling point is what makes vacuum drying so efficient:

1. Lower Temperature Drying: Vacuum drying allows for the drying of temperature-sensitive materials without risking thermal degradation. This is particularly beneficial in industries such as pharmaceuticals, food processing, and chemical manufacturing, where preserving the integrity and efficacy of products is paramount.

2. Increased Speed: The reduced pressure environment accelerates the drying process. When a vacuum is applied, the vapor formed during evaporation is quickly removed, creating a favorable gradient for more vapor to form and be removed, thus speeding up the drying process significantly.

3. Improved Energy Efficiency: Because vacuum drying operates at lower temperatures, it consumes less energy compared to conventional drying methods that often require high temperatures to evaporate water or solvents. This energy savings can translate into significant cost reductions for businesses.

Advantages in Specific Applications

Pharmaceutical Industry

In the pharmaceutical sector, vacuum drying is crucial for the production of active pharmaceutical ingredients (APIs) and intermediates. It ensures that temperature-sensitive compounds are not degraded, preserving their potency and therapeutic effectiveness. Additionally, vacuum drying facilitates the recovery and reuse of expensive solvents, which is both economically advantageous and environmentally responsible.

Food Processing

For food products, vacuum drying is used to preserve nutrients, flavors, and textures. Foods like fruits, vegetables, and herbs can be gently dried without the risk of thermal damage that might alter their nutritional profile or sensory attributes. This process leads to superior quality products that have a longer shelf life and maintain their original qualities better.

Chemical Manufacturing

In chemical manufacturing, vacuum drying is essential for the purification of chemical compounds. It allows for the efficient separation of solvents from solid materials, ensuring the purity of the end product. Solvent recovery is a key aspect here, contributing to both economic and environmental benefits.

Factors Influencing Efficiency

Several factors can affect the efficiency of vacuum drying:

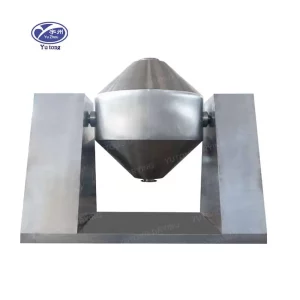

1. Design of the Vacuum Dryer: The design of the vacuum dryer, including its size, shape, and material of construction, can impact its efficiency. Well-designed systems optimize heat transfer and minimize energy losses.

2. Control Systems: Advanced control systems that accurately monitor and adjust parameters such as temperature, pressure, and humidity can greatly enhance the efficiency of the drying process.

3. Maintenance and Cleaning: Regular maintenance and cleaning of the vacuum dryer are necessary to prevent clogging and ensure that the system operates at peak efficiency.

4. Material Properties:The type of material being dried, including its moisture content, particle size, and thermal sensitivity, can affect the efficiency of vacuum drying. Materials that are more difficult to dry may require adjustments in the drying parameters.

Conclusion

Vacuum drying is a highly efficient drying method that excels in various applications due to its ability to dry materials at lower temperatures, increase drying speed, and improve energy efficiency. Its efficiency is further enhanced by its capacity to preserve product quality and facilitate solvent recovery. While the initial investment in vacuum drying equipment can be substantial, the long-term benefits in terms of operational costs, product quality, and environmental impact make it a worthwhile choice for many industries. As technology advances, vacuum drying is expected to become even more efficient and accessible, further solidifying its position as a preferred drying technique in multiple sectors.