The food industry is constantly evolving, with a growing demand for high-quality products that meet strict safety and quality standards. One crucial aspect of food production is the accurate mixing of different powders to achieve the desired taste, texture, and nutritional value. This is where food grade powder mixers play a vital role.

In the complex world of food manufacturing, every step of the process is carefully orchestrated to ensure the end product is not only delicious but also safe for consumption. Powder mixing is a fundamental operation that can significantly impact the quality and consistency of food products. Food grade powder mixers are designed specifically to handle the unique challenges of mixing powders in a food-safe environment.

The Importance of Accurate Powder Mixing

1. Consistency in Product Quality

Accurate mixing of powders is essential for ensuring that each batch of food product has the same taste, texture, and nutritional value. This consistency is crucial for meeting customer expectations and maintaining brand reputation.

2. Optimal Nutritional Content

By precisely mixing different powders, manufacturers can ensure that the final product contains the desired amount of nutrients. This is particularly important for products such as infant formulas, dietary supplements, and functional foods.

3. Enhanced Shelf Life

Proper mixing can help prevent the separation of ingredients, which can lead to spoilage and a shorter shelf life. A homogeneous blend of powders can also improve the stability of the product, reducing the risk of chemical reactions and degradation.

Features of Food Grade Powder Mixers

1. Hygienic Design

Food grade powder mixers are made from materials that are approved for contact with food and are designed to be easy to clean and sanitize. This helps to prevent cross-contamination and ensure the safety of the final product.

2. Gentle Mixing Action

These mixers are designed to handle powders without causing damage or degradation. The gentle mixing action ensures that the powders are mixed thoroughly without creating excessive heat or friction.

3. Versatility

Food grade powder mixers can handle a wide variety of powder materials, including those with different particle sizes, densities, and flow properties. This makes them suitable for a wide range of food applications, from spices and seasonings to flours and starches.

4. Customizable Configurations

Many food grade powder mixers can be customized to meet the specific needs of different food manufacturers. This includes options such as different sizes, mixing speeds, and types of mixing blades.

Different Types of Food Grade Powder Mixers

1. Ribbon Mixers

Ribbon mixers are a popular choice for food grade powder mixing due to their gentle mixing action and ability to handle large volumes of powder. The helical ribbon design ensures that the powders are mixed thoroughly from top to bottom.

2. Paddle Mixers

Paddle mixers use paddles or blades to stir the powder and create a uniform blend. They are suitable for mixing powders with different densities and can handle both dry and wet mixes.

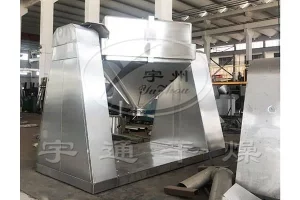

3. Tumbler Mixers

Tumbler mixers work by rotating a drum or container to tumble the powder and achieve a homogeneous blend. They are often used for mixing powders with similar densities and particle sizes.

4. High-Shear Mixers

High-shear mixers are designed for more intense mixing and are often used for powders that are difficult to blend or require a fine dispersion. They use high-speed rotors and stators to create a shearing force that breaks up agglomerates and mixes the powder thoroughly.

Factors to Consider When Choosing a Food Grade Powder Mixer

1. Production Volume

Consider the volume of powder you need to mix on a regular basis. Choose a mixer with a capacity that can handle your production requirements without overloading or underutilizing the equipment.

2. Powder Characteristics

Analyze the properties of the powders you will be mixing, such as particle size, density, and flowability. This will help you determine the type of mixer that is best suited for your specific materials.

3. Mixing Requirements

Consider the degree of mixing required for your product. Some applications may require a gentle mixing action to prevent damage to delicate ingredients, while others may need a more intense mixing to achieve a fine dispersion.

4. Cleanability and Hygiene

Since food safety is a top priority, choose a mixer that is easy to clean and sanitize. Look for features such as removable parts, smooth surfaces, and materials that are resistant to corrosion and bacterial growth.

5. Budget and Cost-Effectiveness

Evaluate the cost of the mixer in relation to its performance and features. Consider the long-term cost of ownership, including maintenance, energy consumption, and replacement parts.

Food grade powder mixers are an essential tool for the food industry, ensuring accurate mixing of different powders to produce high-quality, safe, and consistent food products. By understanding the importance of powder mixing, the features of different types of mixers, and the factors to consider when choosing a mixer, food manufacturers can make informed decisions to optimize their production processes. With the right food grade powder mixer, manufacturers can enhance product quality, increase efficiency, and meet the growing demands of the market.