In the world of industrial processing and manufacturing, the fluid bed dryer has emerged as a crucial piece of equipment. For importers looking to source and utilize this technology, understanding its features, applications, and benefits is essential. This ultimate guide aims to provide a comprehensive overview to help importers make informed decisions.

What is a Fluid Bed Dryer?

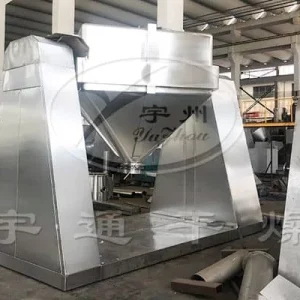

A fluid bed dryer is a specialized drying apparatus that uses a fluidized bed of hot gas to remove moisture from a wide variety of materials. The principle behind its operation is based on the fluidization phenomenon, where a gas (usually air) is passed through a bed of solid particles at a high enough velocity to suspend the particles and create a fluid-like state. This fluid-like behavior allows for excellent heat and mass transfer between the gas and the solid particles, resulting in rapid and uniform drying.

Components of a Fluid Bed Dryer

A typical fluid bed dryer consists of several key components:

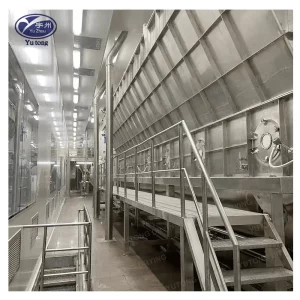

1. Drying Chamber: This is the main enclosure where the drying process takes place. It is usually made of stainless steel or other suitable materials to withstand the operating conditions and prevent corrosion.

2. Gas Distribution System: This system is responsible for evenly distributing the hot gas throughout the drying chamber to ensure uniform fluidization and drying. It typically consists of perforated plates or distributors.

3. Heating System: The heating system provides the necessary heat to the gas, which is then used to evaporate the moisture from the material. Common heating methods include steam coils, hot air generators, or electric heaters.

4. Product Inlet and Outlet: These are the points where the material to be dried is introduced into the dryer and the dried product is removed. They are designed to ensure smooth flow of material and prevent leakage.

5. Control System: The control system monitors and regulates the various parameters of the drying process, such as temperature, gas flow rate, and drying time. It may include sensors, controllers, and valves.

Applications of Fluid Bed Dryers

Fluid bed dryers find extensive applications in various industries due to their versatility and efficiency. Some of the key industries where they are commonly used include:

1. Pharmaceuticals: In the pharmaceutical industry, fluid bed dryers are used for drying granules, powders, and tablets. The gentle drying process and uniform heat transfer are ideal for heat-sensitive pharmaceutical ingredients, ensuring that the active substances are not degraded.

2. Food Processing: The food industry uses fluid bed dryers to dry a wide range of products such as fruits, vegetables, grains, and spices. The rapid drying and preservation of nutritional value make them a valuable tool in food processing.

3. Chemicals: In the chemical industry, fluid bed dryers are used for drying chemicals, pigments, catalysts, and other fine powders. The ability to handle different types of materials and the efficient drying process make them suitable for chemical applications.

4. Minerals and Mining: The minerals industry uses fluid bed dryers to dry minerals, ores, and other mining products. The high drying capacity and ability to handle abrasive materials make them an essential piece of equipment in this sector.

Benefits of Importing a Fluid Bed Dryer

There are several advantages to importing a fluid bed dryer:

1. Improved Product Quality: The uniform drying and gentle handling of materials result in high-quality dried products with consistent properties.

2. Increased Efficiency: The rapid drying process reduces processing time and increases productivity.

3. Energy Savings: Fluid bed dryers are designed to be energy-efficient, reducing operating costs over time.

4. Versatility: They can handle a wide variety of materials, making them suitable for different applications and industries.

5. Advanced Technology: Imported fluid bed dryers often incorporate the latest technological advancements, providing better performance and reliability.

Considerations for Importers

When importing a fluid bed dryer, there are several factors that importers should consider:

1. Quality and Reliability: Look for manufacturers with a reputation for producing high-quality and reliable equipment. Check for certifications and quality control processes.

2. Technical Specifications: Ensure that the dryer meets your specific drying requirements in terms of capacity, temperature range, gas flow rate, and other technical parameters.

3. After-Sales Service: Consider the availability of after-sales service and support, including installation, maintenance, and spare parts availability.

4. Cost: While cost is an important factor, it should not be the sole consideration. Consider the overall value and long-term benefits of the equipment.

5. Compliance and Regulations: Ensure that the imported dryer complies with local safety and environmental regulations.

Installation and Maintenance of Fluid Bed Dryers

Proper installation and maintenance are crucial for the optimal performance and longevity of a fluid bed dryer. Here are some important points to consider:

1. Installation: Follow the manufacturer’s instructions carefully during installation. Ensure that the dryer is installed on a stable foundation and connected to the necessary utilities.

2. Maintenance: Regular maintenance is essential to keep the dryer in good condition. This may include cleaning the drying chamber, inspecting the gas distribution system, and checking the heating elements.

3. Spare Parts: Keep a stock of essential spare parts to minimize downtime in case of breakdowns.

4. Training: Provide proper training to operators to ensure safe and efficient operation of the dryer.

In conclusion, importing a fluid bed dryer can be a valuable investment for businesses in various industries. By understanding the features, applications, and benefits of this technology, and considering the important factors during the import process, importers can make informed decisions and choose the right dryer for their specific needs. With proper installation and maintenance, a fluid bed dryer can provide years of reliable service and contribute to improved productivity and product quality.