In the realm of industrial processing, efficient drying of bulk materials is crucial for ensuring product quality, reducing waste, and maximizing productivity. Fluid bed dryers have emerged as a highly effective solution for handling bulk processes, offering a range of benefits and capabilities that make them an essential tool in many industries.

The fluid bed drying process is based on the principle of fluidization, where a gas (usually air) is passed through a bed of solid particles at a high enough velocity to suspend the particles and create a fluid-like state. This fluid-like behavior allows for excellent heat and mass transfer between the gas and the solid particles, resulting in rapid and uniform drying.

For bulk processes, fluid bed dryers offer several key advantages. Firstly, they can handle large volumes of material, making them ideal for industries that deal with high production rates. Whether it’s drying grains, chemicals, pharmaceuticals, or minerals, fluid bed dryers can efficiently process large batches of material in a relatively short amount of time.

One of the main benefits of using a fluid bed dryer for bulk processes is the uniformity of drying. The fluidized bed ensures that every particle of the material is exposed to the same drying conditions, resulting in consistent drying throughout the batch. This is particularly important for materials that require precise moisture control or have strict quality specifications. For example, in the pharmaceutical industry, fluid bed dryers are used to dry active ingredients and excipients to ensure consistent drug quality.

Another advantage of fluid bed dryers for bulk processes is their energy efficiency. The efficient heat transfer and short drying times mean that less energy is required to dry the material compared to traditional drying methods. This can lead to significant cost savings over time, especially for large-scale operations. Additionally, fluid bed dryers can be designed to recover and reuse waste heat, further reducing energy consumption.

Fluid bed dryers also offer flexibility in terms of process control. The drying parameters such as temperature, gas flow rate, and drying time can be easily adjusted to meet the specific requirements of different materials and processes. This allows for optimal drying conditions to be achieved, ensuring high-quality dried products. For instance, in the food industry, fluid bed dryers can be used to dry a variety of products such as fruits, vegetables, and grains while preserving their nutritional value and flavor.

In addition to drying, fluid bed dryers can also be used for other processes such as cooling, coating, and agglomeration. This multi-functionality makes them a versatile tool for bulk processes, reducing the need for multiple pieces of equipment and saving space and cost. For example, fluid bed coolers can be used to quickly cool down hot materials after drying, while fluid bed coaters can be used to apply a protective or functional coating to the material.

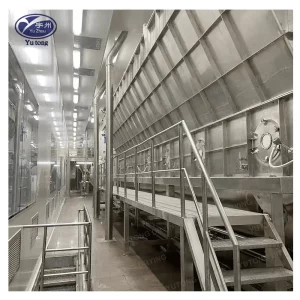

When it comes to choosing a fluid bed dryer for bulk processes, there are several factors to consider. These include the type of material to be dried, the production rate, the required drying capacity, and the available space and budget. Different types of fluid bed dryers are available, including batch and continuous models, as well as different configurations such as rectangular, cylindrical, and conical designs. Each type has its own advantages and disadvantages, and the choice depends on the specific requirements of the application.

For example, batch fluid bed dryers are suitable for small to medium-sized batches and offer flexibility in operation. They can be loaded with the material, dried, and then unloaded, allowing for easy cleaning and maintenance between batches. Continuous fluid bed dryers, on the other hand, are designed for large-scale production and provide a continuous flow of material through the dryer. These dryers are often used in industries where high throughput is required.

In conclusion, fluid bed dryers offer a highly effective solution for bulk processes, providing rapid, uniform, and energy-efficient drying. Their versatility and flexibility in process control make them an essential tool in many industries, from food and pharmaceuticals to chemicals and minerals. By carefully considering the specific requirements of the application and choosing the right type of fluid bed dryer, businesses can optimize their drying processes and improve product quality and productivity.