In the ever-evolving landscape of manufacturing and processing industries, film coating machines have emerged as indispensable tools. Whether it’s in the pharmaceutical sector for coating tablets to enhance their stability and appearance or in the food industry for adding a protective layer to confectionery, these machines play a crucial role. As we step into 2024, understanding the ins and outs of choosing the right film coating machine becomes even more vital.

The Significance of Film Coating Machines

Film coating serves multiple purposes across different industries. In pharmaceuticals, it can mask unpleasant tastes or odors, protect active ingredients from degradation, and control the release rate of drugs. In the food industry, it can improve the shelf life of products, enhance their appearance, and provide a barrier against moisture and oxygen. Additionally, in other sectors like cosmetics and chemicals, film coating can add functionality and aesthetic appeal.

A high-quality film coating machine ensures consistent results, reducing product variability and enhancing overall quality. It can also increase production efficiency by automating the coating process and minimizing downtime.

Understanding the Different Types of Film Coating Machines

1. Pan Coaters

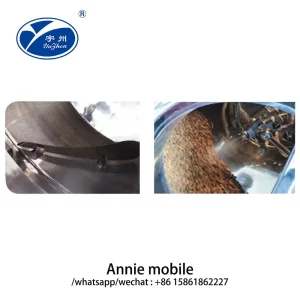

Pan coaters are known for their simplicity and versatility. They consist of a rotating pan or drum where the products to be coated are placed. As the pan rotates, the coating material is sprayed onto the products, creating a uniform layer. Pan coaters are suitable for a wide range of products, from small tablets to larger pellets. They are often preferred for their ease of use and cost-effectiveness.

However, pan coaters may have limitations in terms of coating uniformity for some products. The rotation speed and spraying pattern can affect the quality of the coating, and adjustments may be required to achieve optimal results.

2. Fluid Bed Coaters

Fluid bed coaters use a stream of air to suspend the products in a fluidized state. The coating material is then sprayed onto the suspended products, resulting in a more even coating compared to pan coaters. This type of machine is ideal for products that are sensitive to heat or require a more controlled coating process.

Fluid bed coaters offer several advantages, including better coating uniformity, faster drying times, and the ability to handle a wide range of particle sizes. However, they can be more complex and expensive than pan coaters.

3. Spray Coaters

Spray coaters are designed to apply the coating material directly onto the products using a spray nozzle. They can be used for a variety of applications, including coating small batches of products or applying specialized coatings. Spray coaters are often more compact and cost-effective than pan or fluid bed coaters.

However, spray coaters may have limitations in terms of coating thickness and uniformity. They may also require more frequent maintenance and cleaning due to the potential for clogging of the spray nozzle.

Key Features to Look for in a Film Coating Machine

1. Capacity and Throughput

Determine the production volume you need to coat and choose a machine with an appropriate capacity. Consider both the batch size and the throughput rate to ensure that the machine can meet your production demands without causing bottlenecks.

For example, if you are a large-scale pharmaceutical manufacturer, you may need a machine with a high capacity and throughput to handle large volumes of tablets. On the other hand, a small-scale confectionery producer may be able to get by with a smaller machine with a lower throughput.

2. Coating Uniformity

This is one of the most critical features to consider. A good film coating machine should be able to provide consistent and uniform coating across all products. Look for machines with advanced spraying systems, precise air flow control, and adjustable rotation speeds to ensure optimal coating uniformity.

You can evaluate coating uniformity by inspecting sample products coated by the machine. Look for even coverage, without any areas of excessive or insufficient coating. Additionally, ask the supplier for data on coating uniformity specifications and test results.

3. Control System

A sophisticated control system is essential for precise control of the coating process. Look for a machine with features such as programmable logic controllers (PLCs), touchscreen interfaces, and real-time monitoring capabilities. This will allow you to fine-tune the coating parameters and ensure reproducible results.

The control system should also be user-friendly and intuitive, allowing operators to easily set up and adjust the coating process. Look for machines with clear instructions and user manuals, as well as training and support from the supplier.

4. Compatibility with Coating Materials

Make sure the machine is compatible with the types of coating materials you plan to use. Different coating materials have different properties, such as viscosity, melting point, and solubility. The machine should be able to handle these materials without any issues.

Check with the supplier for a list of compatible coating materials and ask for recommendations based on your specific application. Additionally, consider the availability and cost of the coating materials you plan to use, as this can impact your overall production costs.

5. Cleanability and Maintenance

Ease of cleaning and maintenance is important for ensuring product quality and minimizing downtime. Look for a machine with a design that allows for easy access to all parts for cleaning and inspection. Consider features such as removable spray nozzles, washable pans, and self-cleaning systems.

Regular maintenance is also crucial to keep the machine in good working condition. Ask the supplier about the recommended maintenance schedule and procedures, as well as the availability of spare parts and service support.

6. Energy Efficiency

As energy costs continue to rise, energy efficiency is an important consideration. Look for a machine that uses energy-efficient components, such as low-power motors and LED lighting. Consider the machine’s overall power consumption and compare it to other models to ensure you are getting the best value for your money.

Energy-efficient machines not only save on operating costs but also contribute to a more sustainable production process. Look for machines with energy-saving features such as automatic shut-off when not in use and adjustable power settings.

7. Safety Features

Film coating machines can involve the use of chemicals and high temperatures, so safety is a top priority. Look for machines with features such as safety interlocks, emergency stop buttons, and explosion-proof designs. Ensure that the machine complies with all relevant safety standards and regulations.

Provide proper training to operators on safety procedures and ensure that safety guidelines are followed at all times. Regular inspections and maintenance of safety features can also help prevent accidents and ensure a safe working environment.

Choosing the Right Supplier

1. Reputation and Experience

Choose a supplier with a proven track record and extensive experience in the film coating machine industry. Look for reviews and testimonials from other customers to get an idea of the supplier’s reliability and quality of service.

A supplier with a long history of providing high-quality machines and excellent customer support is more likely to meet your needs. Check their website, social media pages, and industry forums for feedback from other users.

2. Technical Support and After-Sales Service

A good supplier should offer comprehensive technical support and after-sales service. This includes installation, training, maintenance, and repair services. Make sure the supplier has a team of trained technicians who can quickly respond to any issues that may arise.

Ask about the supplier’s warranty policy and after-sales support options. A longer warranty period and prompt response times can give you peace of mind and ensure minimal downtime in case of any problems.

3. Customization Options

If you have specific requirements or unique applications, look for a supplier who can offer customization options. This may include modifying the machine’s design, adding specialized features, or developing a custom coating process.

A supplier who is willing to work with you to meet your specific needs can provide a more tailored solution and ensure that the machine is optimized for your particular application.

4. Price and Value

While price is an important consideration, don’t sacrifice quality for a lower price. Consider the overall value of the machine, including its features, performance, and after-sales service. Compare prices from different suppliers to ensure you are getting the best deal.

Look for suppliers who offer competitive pricing without compromising on quality. Consider the long-term costs of ownership, including maintenance, energy consumption, and replacement parts, when evaluating the price of a machine.

Selecting the right film coating machine in 2024 requires careful consideration of various factors. Understanding the different types of machines available, their key features, and the importance of choosing a reliable supplier can help you make an informed decision. By investing in a high-quality film coating machine, you can enhance the quality and functionality of your products, increase production efficiency, and stay ahead of the competition. Whether you are in the pharmaceutical, food, or any other industry that requires film coating, taking the time to choose the right machine is a crucial step towards success.