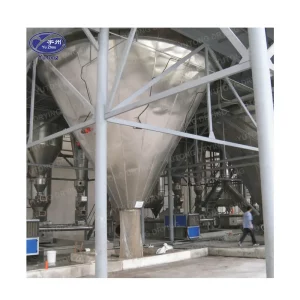

Enzyme Spray Dryer

Project description:

The company according to the material properties of the enzyme preparation, the successful development of the Spray Dryer enzymes. This machine is a high-speed centrifugal atomization allows material dispersed into a mist, complete with hot air full access to instant dried to form a powder drying means finished. Air to go through at the beginning, in effect filters, after heated by the heater into the dryer at the top of the air distributor, the hot air evenly into the spiral form the drying chamber, and contacting the heat air in a very short time can be dried into German finished.

Item Description:

Enzymes extracted from a biological means having the enzymatic properties of a class of substances, the main role is

Device Description:

This machine is a high-speed centrifugal atomization allows material dispersed into a mist, complete with hot air full access to instant dried to form a powder drying means finished. Air to go through at the beginning, in effect filters, after heated by the heater into the dryer at the top of the air distributor, the hot air evenly into the spiral form the drying chamber, and contacting the heat air in a very short time can be dried into German finished. Finished continuously from the bottom of the cyclone efficiency, exhaust gas discharged from the induced draft fan.

Features:

(1) centrifugal spray dryer is the use of high-speed centrifugal atomization allows material dispersed into a mist, complete with hot air full access to instant dried to form a powder drying means finished.

(2) This device is equipped with air intake means sub-high efficiency filter, so that the supply air reached 100,000 purification.

(3) inlet air temperature control, thus ensuring the material color, smell and taste will not be destroyed.

(4) the entire operating system is simple to understand, to make workers to operate more convenient and equipment temperature instrumentation and pressure instrument can always detect the major control point temperature and pressure.

(5) in the tower, pipeline cleaning with quick opening hole and sewage hole, and thus easy to clean, in line with GMP practices.

(6) The device is equipped with an air hammer rapping device.

(7) equipment uses two cyclone collector, the discharged gas reaches a production process needs.

(8) Wet dust handling equipment exhaust, the discharged gas reaches the national environmental protection requirements relating.

Products real shot pictures: