In the world of preservation and drying techniques, freeze drying and vacuum drying are two popular methods often discussed. They both serve the purpose of removing moisture from products, yet the processes, results, and applications differ significantly. In this article, we’ll delve into the distinctions between freeze drying and vacuum drying, exploring their processes, benefits, and ideal applications.

Understanding Freeze Drying

Freeze drying, also known as lyophilization, is a method used to preserve perishable materials. It works by freezing the product and then reducing the surrounding pressure to allow the frozen water in the material to sublimate directly from the solid phase to the gas phase. This process is highly effective in preserving the structural integrity and nutritional content of the product.

The Freeze Drying Process

Freezing Phase

The initial step in freeze drying involves lowering the product’s temperature well below its freezing point. This ensures that all the moisture within the product solidifies into ice. By achieving this solid state, the product’s intrinsic structure is maintained, setting the foundation for the subsequent drying phases.

Primary Drying (Sublimation)

During the primary drying phase, the surrounding pressure is significantly reduced, creating an environment conducive to sublimation. Heat is carefully applied to convert ice directly into water vapor, bypassing the liquid phase entirely. This step is crucial as it eliminates approximately 95% of the moisture, ensuring the product’s core components remain intact.

Secondary Drying (Desorption)

The final stage, secondary drying, targets the removal of water molecules that are still bound to the material. By slightly increasing the temperature, these molecules are released, ensuring the product is thoroughly dry. This phase not only guarantees dryness but also contributes to the product’s enhanced stability and shelf life.

Benefits of Freeze Drying

Preservation of Quality

One of the standout benefits of freeze drying is its ability to retain the product’s original structure, flavor, and color. This unique preservation method ensures that even after moisture removal, the product remains visually and texturally appealing, maintaining its original allure. This knowledge empowers you to make informed decisions about preservation techniques.

Nutrient Retention

Freeze drying is particularly beneficial for preserving nutritional content. By minimizing heat exposure, essential vitamins and minerals remain intact, making this method ideal for food products and pharmaceuticals where nutrient preservation is paramount.

Long Shelf Life and Lightweight

Products that undergo freeze drying can be stored for extended periods without the need for refrigeration, thanks to the thorough removal of moisture. Additionally, the significant reduction in weight makes these products easier and more cost-effective to transport, appealing to industries focused on logistics efficiency.

Applications of freeze-drying

Food Industry

In the food sector, freeze-drying is extensively used to preserve a variety of products, including fruits, vegetables, and meats. The method ensures that these items maintain their nutritional value and flavor, appealing to consumers seeking high-quality, long-lasting food options.

Pharmaceuticals

The pharmaceutical industry relies on freeze-drying to stabilize vaccines and other sensitive drugs. This method ensures that critical medications retain their efficacy and safety over time, even when stored at ambient temperatures.

Biological Samples and Space Exploration

Beyond food and pharmaceuticals, freeze-drying plays a vital role in preserving biological samples for scientific research. Furthermore, it is instrumental in the preparation of astronaut food, where long shelf life and nutrient retention are critical for space missions.

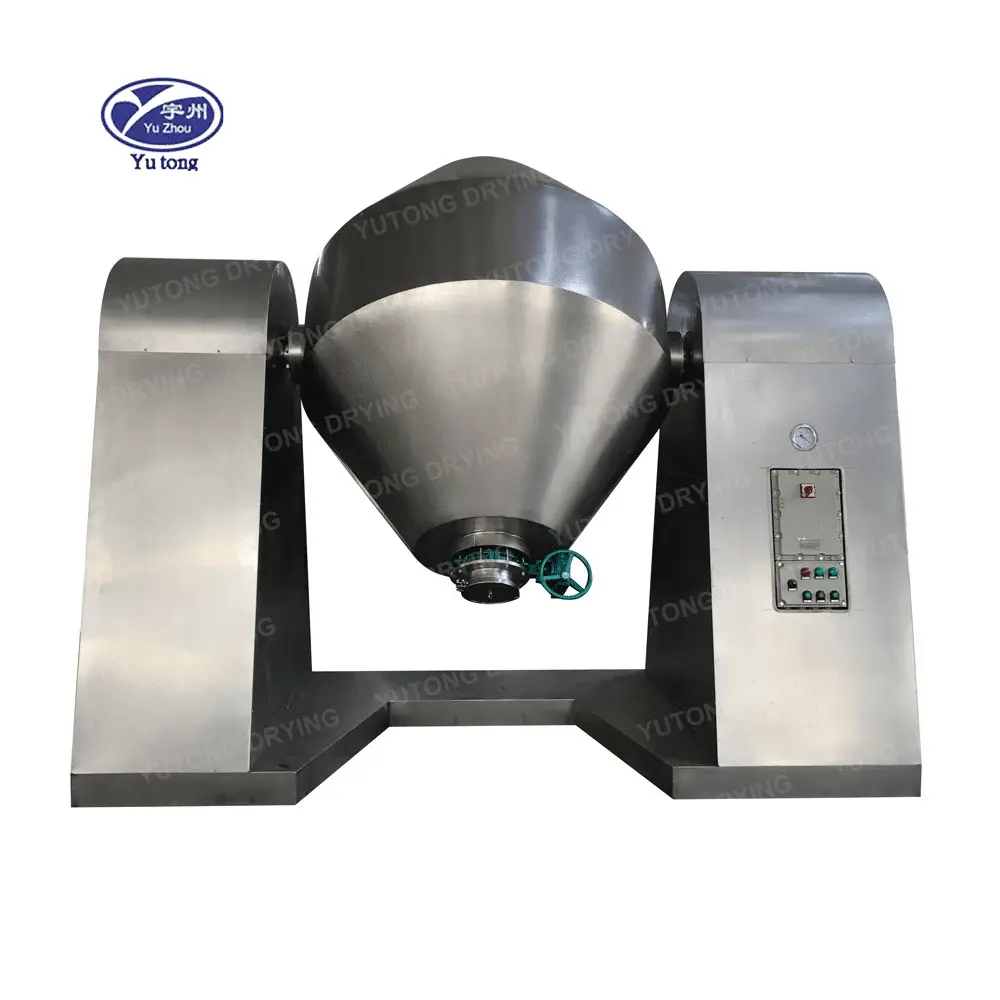

Understanding Vacuum Drying

Vacuum drying is a process that removes moisture by applying a vacuum to lower the pressure around the product, which decreases the boiling point of water. This allows for drying at lower temperatures compared to conventional drying methods, making it suitable for heat-sensitive materials.

The Vacuum Drying Process

Loading Phase

The vacuum drying process begins with the careful placement of the material into a vacuum chamber. This initial setup is crucial, as it ensures that the product is evenly distributed, allowing for consistent drying once the vacuum is applied.

Vacuum Application

Once the product is securely loaded, the chamber is sealed, and a vacuum pump is activated to reduce the pressure inside. This reduction in pressure lowers the boiling point of water, setting the stage for efficient moisture removal at lower temperatures.

Heat Application

To expedite the drying process, gentle heat is applied to the product. This heat facilitates the evaporation of moisture, allowing it to escape even at the reduced temperatures achieved under vacuum conditions. This step ensures the product dries evenly without the risk of overheating.

Continuous Moisture Removal

As water evaporates from the product, it is continuously extracted from the chamber. This ongoing removal of moisture ensures that the drying process is thorough, leaving the product dry and ready for subsequent use or packaging.

Benefits of Vacuum Drying

Energy Efficiency

Vacuum drying is known for its energy efficiency, as it requires less energy input than traditional drying methods. By operating at lower temperatures, this method reduces energy consumption, offering cost savings for businesses focused on sustainable operations. This reassurance about its sustainability can guide your decision-making process.

Gentle Drying for Heat-Sensitive Products

The ability to dry products at lower temperatures makes vacuum drying particularly suitable for heat-sensitive materials. This gentle drying approach prevents damage or degradation, preserving the product’s integrity and quality throughout the process.

Uniform Drying

Vacuum drying ensures even moisture removal across the entire product. This uniform drying prevents localized overheating or under-drying, ensuring the final product is consistent in quality and performance.

Applications of Vacuum Drying

Chemical and Pharmaceutical Industries

In the chemical and pharmaceutical sectors, vacuum drying is widely used for drying heat-sensitive powders and granules. The method ensures that these materials are dried without compromising their chemical structure or efficacy.

Food Industry

Within the food industry, vacuum drying is employed for products that require gentle handling, such as herbs and spices. The method preserves the delicate flavors and aromas of these products, enhancing their appeal to consumers.

Electronics and Polymers

Vacuum drying is also instrumental in the production of certain polymers and the drying of electronic components. The method ensures these materials are free from moisture, preventing potential damage or malfunction during use.

Key Differences Between Freeze Drying and Vacuum Drying

Process Differences

Freeze Drying

Freeze drying involves a complex process of freezing and sublimation. This method requires precise control of temperature and pressure to convert ice directly into vapor, bypassing the liquid phase entirely.

Vacuum Drying

In contrast, vacuum drying relies on evaporation at reduced pressure. This process operates at moderate temperatures, using a vacuum to lower the boiling point of water, facilitating moisture removal without the need for freezing.

Product Quality

Structure and Nutrients

Freeze drying is renowned for its ability to preserve the structure and nutritional content of products. The method maintains the product’s original characteristics, ensuring it remains visually and nutritionally appealing.

Texture

The texture of freeze-dried products is often more porous and crunchy, providing a unique sensory experience. In comparison, vacuum-dried products may have a denser texture, which can be advantageous for certain applications where a compact form is desired.

Cost and Time

Cost Implications

Freeze drying generally incurs higher costs due to the complexity and duration of the process. The need for specialized equipment and extended processing times contributes to the overall expense.

Time Efficiency

When it comes to time, freeze-drying takes longer compared to vacuum drying. The multiple steps involved in freeze drying, such as freezing and sublimation, require careful execution, extending the overall process duration.

Choosing the Right Method

When deciding between freeze drying and vacuum drying, consider the nature of the product, desired quality, and budget constraints. Freeze drying is ideal for high-value, sensitive products where quality preservation is crucial. In contrast, vacuum drying is suitable for bulk materials where cost and efficiency are more critical.

Assessing Product Sensitivity

Understanding the sensitivity of the product to heat and moisture is essential in choosing the right method. Products that are highly sensitive to heat or require the preservation of delicate structures and nutrients are best suited for freeze-drying. This guidance can instill confidence in your choice of preservation method.

Evaluating Budget Constraints

Budget considerations play a significant role in the decision-making process. While freeze drying offers superior quality retention, it comes at a higher cost. Businesses must weigh the benefits of enhanced quality against the financial implications.

Desired Quality and Outcome

The desired quality and outcome of the drying process are pivotal factors. If maintaining the original texture, color, and nutritional content is a priority, freeze-drying is the preferred option. However, for applications where cost efficiency and quick processing are more important, vacuum drying may be a better choice.

Conclusion

Both freeze-drying and vacuum-drying offer unique advantages and are essential in various industries. Understanding their differences helps in selecting the most appropriate method for specific applications. Whether you aim to preserve food, pharmaceuticals, or other materials, knowing the strengths of each drying technique can significantly impact the quality and efficiency of your production processes.

In summary, both methods serve the purpose of moisture removal, yet they cater to different needs based on the product’s sensitivity, budget, and desired outcome. By leveraging the appropriate drying technique, businesses can enhance product quality, optimize costs, and improve overall efficiency.

Final Thoughts

The choice between freeze drying and vacuum drying is not one-size-fits-all. Each method has its own set of benefits and challenges, making it crucial for businesses to evaluate their specific needs thoroughly. Whether prioritizing cost, quality, or speed, understanding these drying techniques is key to making informed decisions that align with business goals and consumer expectations.