Table of Contents

Product Detail

In the world of industrial drying, efficiency and effectiveness are key. One such technology that stands out is the double-cone vacuum dryer. These machines are essential for drying heat-sensitive materials, making them invaluable in industries such as pharmaceuticals, food processing, and chemicals. In this article, we’ll delve into the workings, benefits, and applications of double-cone vacuum dryers, as well as provide some insights into DIY vacuum drying solutions.

Understanding the Double Cone Vacuum Dryer

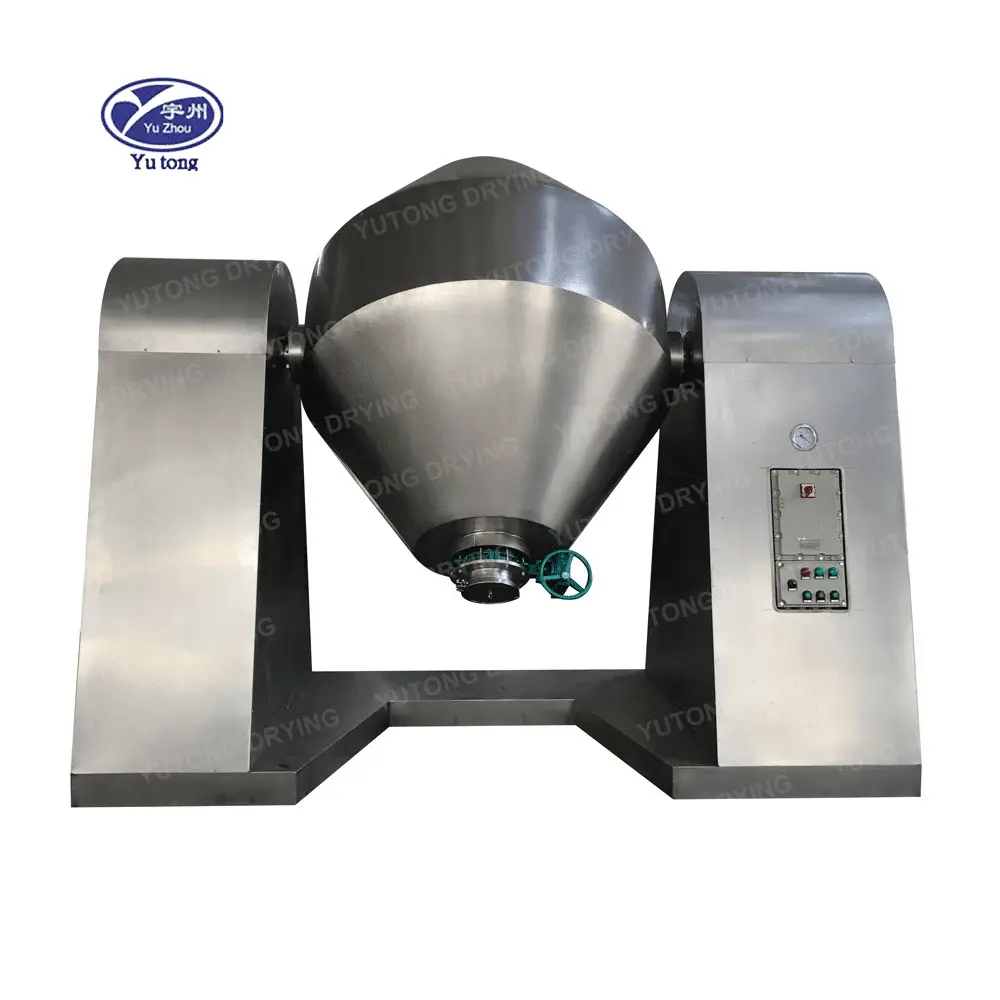

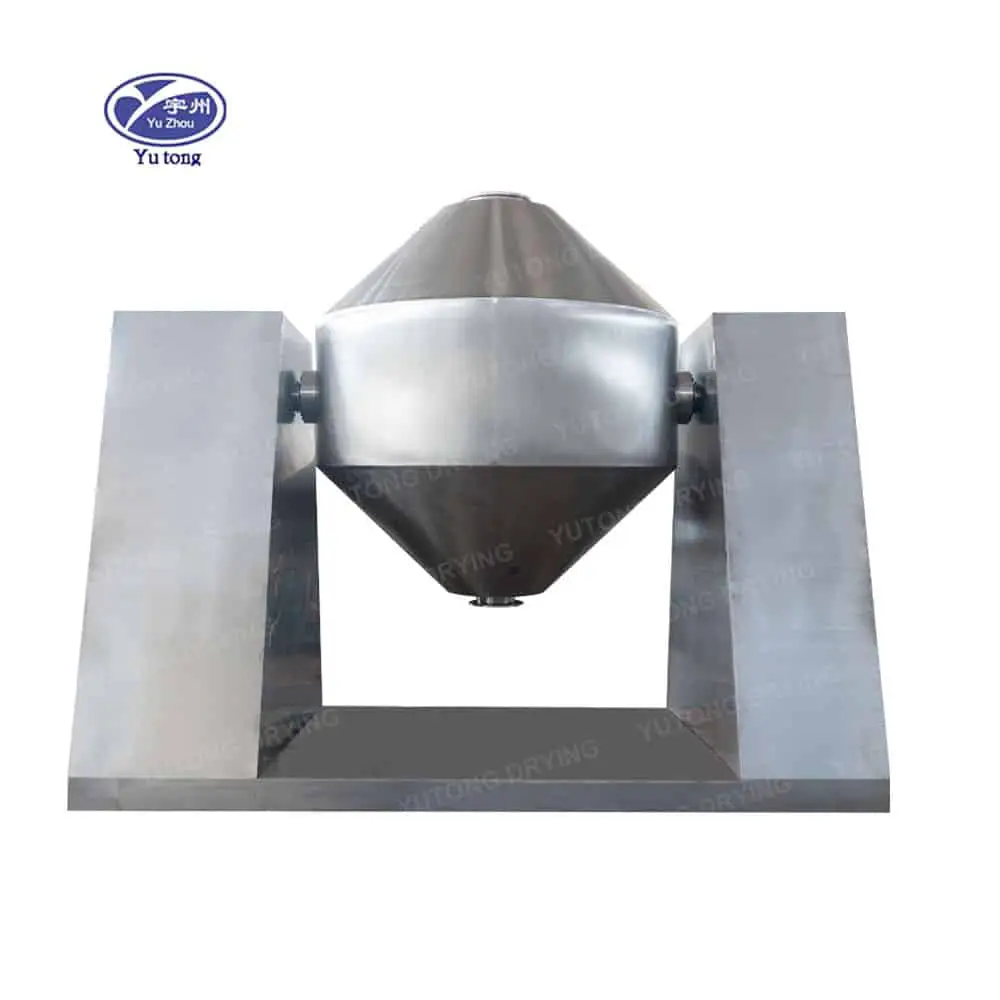

A double-cone vacuum dryer is designed to dry materials under vacuum. It comprises a rotating double-cone chamber that ensures uniform drying by tumbling the material within and exposing it to the drying surface. This gentle mixing action helps preserve the integrity of heat-sensitive materials, making it ideal for delicate products.

The Structure of a Double-Cone Vacuum Dryer

The double-cone vacuum dryer consists of a unique design featuring two conical sections joined together. This structure allows for optimal tumbling and mixing of materials, ensuring that every particle comes in contact with the drying surface. The construction materials are typically stainless steel to prevent contamination and ensure durability.

The machine is also equipped with a vacuum system that reduces the pressure inside the chamber. This component is crucial in creating an environment where moisture evaporates at lower temperatures, preserving the quality of the materials.

The Role of Vacuum in Drying

The vacuum plays a pivotal role in the drying process by significantly lowering the boiling point of liquids within the materials. This means that even at lower temperatures, the moisture can evaporate, thereby protecting heat-sensitive substances from thermal degradation. The vacuum ensures that the drying is not only efficient but also gentle, retaining the characteristics of delicate products.

Rotation and Tumbling Mechanism

The rotation and tumbling mechanism is central to the uniform drying process. By continuously moving the materials within the chamber, the dryer ensures that each particle is evenly exposed to the drying surface. This movement reduces the risk of material clumping or forming hotspots, which can lead to uneven drying or degradation of certain sections of the product.

Applications of Double Cone Vacuum Dryers

Double-cone vacuum dryers are versatile and find applications across various industries. Here are some common uses:

Pharmaceuticals

In the pharmaceutical industry, double-cone vacuum dryers are used for drying active pharmaceutical ingredients (APIs) and intermediates. The gentle drying process helps maintain the quality and efficacy of the drug compounds.

Preserving Drug Efficacy

The pharmaceutical industry relies heavily on maintaining the efficacy of drug compounds. Double-cone vacuum dryers play a critical role in this by ensuring that the active ingredients are not exposed to high temperatures, which could degrade their effectiveness. This precision is crucial for producing reliable and safe medications.

Compliance with Industry Standards

Stringent regulations govern the quality and safety of products in the pharmaceutical sector. Double-cone vacuum dryers meet these standards by offering controlled and consistent drying processes. Their ability to handle sensitive materials without compromising quality makes them indispensable in pharmaceutical manufacturing.

Food Processing

For food processing, double-cone vacuum dryers are employed to dry fruits, vegetables, and other food products. This method retains the food’s nutritional value and flavor, making it an excellent choice for producing high-quality dried foods.

Retaining Nutritional Value

Preserving the nutritional value of food is paramount in food processing. Double cone vacuum dryers facilitate this by allowing drying at lower temperatures, which helps retain essential nutrients and flavors. This is particularly important for fruits and vegetables, where vitamins and minerals must be preserved.

Enhancing Shelf Life

The drying process using double-cone vacuum dryers also extends the shelf life of food products. By efficiently removing moisture, these dryers prevent microbial growth and spoilage, ensuring that food products remain safe and consumable for extended periods.

Chemicals

In chemical manufacturing, double-cone vacuum dryers are utilized for drying fine chemicals, catalysts, and other sensitive materials. The controlled drying environment ensures product stability and quality.

Stability of Chemical Compounds

Chemical products often require a stable environment to maintain their properties. Double cone vacuum dryers provide this by offering a gentle drying process that prevents chemical reactions that could alter the product’s characteristics. This stability is crucial for chemicals that are sensitive to heat and moisture.

Production of High-Purity Chemicals

The precision of double-cone vacuum dryers ensures that chemicals are dried to a high degree of purity. This is essential for applications where even small impurities can significantly impact the performance of the chemical product. The dryers’ ability to uniformly remove moisture without introducing contaminants is a key advantage in chemical manufacturing.

The Benefits of Using Double-Cone Vacuum Dryers

There are several advantages to using double-cone vacuum dryers:

Energy Efficiency

Double cone vacuum dryers consume less energy than conventional drying methods. The vacuum reduces the solvent’s boiling point, allowing drying to occur at lower temperatures and resulting in energy savings.

Lower Operational Costs

Double-cone vacuum dryers lower operational costs by utilizing less energy. This is a significant benefit for industries seeking to minimize expenses while maintaining high production standards. The reduction in energy consumption also aligns with environmental sustainability goals.

Reduced Carbon Footprint

In addition to cost savings, the energy-efficient operation of double-cone vacuum dryers helps reduce the carbon footprint of manufacturing processes. This is increasingly important as industries strive to adopt greener practices and reduce their impact on the environment.

Preservation of Product Quality

The gentle tumbling action and low-temperature drying preserve the material’s quality, color, and flavor, making it ideal for sensitive products like pharmaceuticals and food.

Maintaining Aesthetic Appeal

Maintaining aesthetic appeal is vital for products where appearance is crucial, such as food items and pharmaceuticals. Double-cone vacuum dryers ensure that the color and texture of products remain intact, enhancing their marketability and consumer appeal.

Protecting Sensitive Ingredients

Sensitive ingredients, such as flavors, colors, or active compounds, require careful handling during the drying process. The controlled environment provided by double-cone vacuum dryers ensures that these elements are preserved, maintaining the product’s intended effects and characteristics.

Uniform Drying

The rotational movement ensures that all parts of the material are exposed to the drying surface, resulting in uniform drying and reducing the risk of hotspots or uneven drying.

Consistency in Product Quality

Uniform drying ensures that every batch of product is consistent in quality. This consistency is crucial for industries where product uniformity is a measure of quality, such as pharmaceuticals and food processing. It also reduces the need for reprocessing, saving time and resources.

Minimizing Waste

By ensuring even drying, double cone vacuum dryers minimize waste due to unevenly dried or overheated sections of the product. This efficiency leads to better yield and less material wastage, positively impacting overall production efficiency.

DIY Vacuum Dryer Solutions

For those interested in small-scale or home-based drying, DIY vacuum dryers can be a practical solution. While building a vacuum dryer at home can be challenging, it’s not impossible. Here’s a basic overview of how to construct a simple vacuum dryer:

How to Make a DIY Vacuum Dryer

- Materials Needed: A vacuum pump, a sealed chamber (like a pressure cooker or a glass jar with a tight-fitting lid), and a heat source (like a heating pad).

Selecting the Right Materials

The choice of materials is crucial when constructing a DIY vacuum dryer. It’s important to select components that can withstand vacuum conditions and temperature variations. Using high-quality, durable materials will ensure the longevity and safety of your homemade dryer.

- Setup: Attach the vacuum pump to the chamber to create a vacuum. Place the material to be dried inside the chamber.

Ensuring a Proper Seal

Achieving a proper seal is essential for the vacuum to be effective. The chamber should be airtight to prevent air leaks that could disrupt the drying process. Properly securing all connections will ensure that the vacuum environment is maintained consistently.

- Operation: Turn on the vacuum pump to lower the pressure inside the chamber. Apply gentle heat using the heat source to facilitate drying.

Monitoring and Adjustments

During operation, continuous monitoring is necessary to ensure that the drying process is proceeding as expected. Adjustments in heat and pressure may be required to achieve optimal drying conditions without overheating or damaging the material.

- Monitoring: Keep an eye on the drying process to ensure that the material is drying evenly and not overheating.

Safety and Efficiency Checks

Regular checks during the drying process help ensure the safety and efficiency of your DIY setup. Monitoring temperature and pressure will help in making any necessary adjustments to maintain an even drying process and prevent potential hazards.

Safety Considerations

Safety should be a top priority when building a DIY vacuum dryer. Ensure that all components are suitable for vacuum use and can withstand the pressure changes. Avoid using materials that might break or shatter under vacuum conditions.

Handling Equipment Safely

Proper handling and operation of the equipment are paramount to prevent accidents. Ensure that you understand how each component functions and follows safe practices, such as wearing protective gear and using equipment as intended.

Avoiding Potential Hazards

Being aware of potential hazards, such as implosions or overheating, is crucial. Regular maintenance and inspection of your DIY dryer will help identify any issues that could lead to safety risks. Taking preventative measures will ensure a safe and successful drying process.

Conclusion

Double-cone vacuum dryers are a vital tool in industries where product quality and efficiency are paramount. Whether used in large-scale industrial applications or DIY projects, these dryers offer numerous benefits, including energy efficiency, preservation of product quality, and uniform drying. By understanding the principles and applications of double-cone vacuum dryers, you can make informed decisions about incorporating this technology into your drying processes.

Whether you’re a professional in the pharmaceutical, food, or chemical industry or a DIY enthusiast looking to explore vacuum drying at home, the double-cone vacuum dryer offers a versatile and effective solution. Embrace the technology and experience the advantages it brings to your drying operations.

The Future of Drying Technologies

As industries continue to evolve, the demand for efficient and reliable drying technologies will increase. Double cone vacuum dryers, with their energy efficiency and ability to preserve product quality, will play a crucial role in meeting these demands. Innovations and advancements in this technology will likely enhance their capabilities and broaden their applications, solidifying their place in modern manufacturing processes.

Embracing Sustainable Practices

The growing emphasis on sustainability and energy conservation will further drive the adoption of double-cone vacuum dryers. Their ability to minimize energy consumption and reduce waste makes them an attractive option for companies looking to implement greener practices. By embracing these dryers, industries can contribute to a more sustainable future while achieving their production goals.

Exploring New Applications

As the understanding and technology of double-cone vacuum dryers advance, new applications across various industries will emerge. From biotechnology to advanced materials, the versatility and effectiveness of these dryers will open new opportunities for innovation and efficiency. Keeping abreast of these developments will enable industries and individuals to leverage this technology to its fullest potential.

Specifications

|

Model

|

100

|

500

|

1000

|

1500

|

2000

|

5000

|

|

Volume (L)

|

100

|

500

|

1000

|

15000

|

2000

|

5000

|

|

Maximum Loading Volume (L)

|

40

|

200

|

400

|

600

|

800

|

2000

|

|

Maximum Loading Capacity (kg)

|

20

|

100

|

200

|

300

|

400

|

1000

|

|

Rotating Speed (rpm)

|

3~13

|

6

|

5

|

4

|

||

|

Motor Power (k w)

|

0.75

|

1.5

|

3

|

4

|

5.5

|

15

|

|

Floor Area (mm)

|

2160 × 800

|

2350× 800

|

2860 × 1300

|

3060 × 1300

|

3260 × 1400

|

4400 × 2500

|

|

Rotation Height (mm)

|

1750

|

2250

|

2800

|

2940

|

2990

|

4200

|

|

Design Pressure In Container (MPa)

|

-0.09 to 0.096

|

|||||

|

Interlayer Design Pressure (MPa)

|

≤ 0.3

|

|||||

|

Weight (kg)

|

800

|

1200

|

2800

|

3300

|

3600

|

8600

|

Applications

Applicable Industries: Machinery Repair Shops, Food & Beverage Factory, Farms, Retail, Food Shop, Energy & Mining, Food & Beverage Shops