Table of Contents

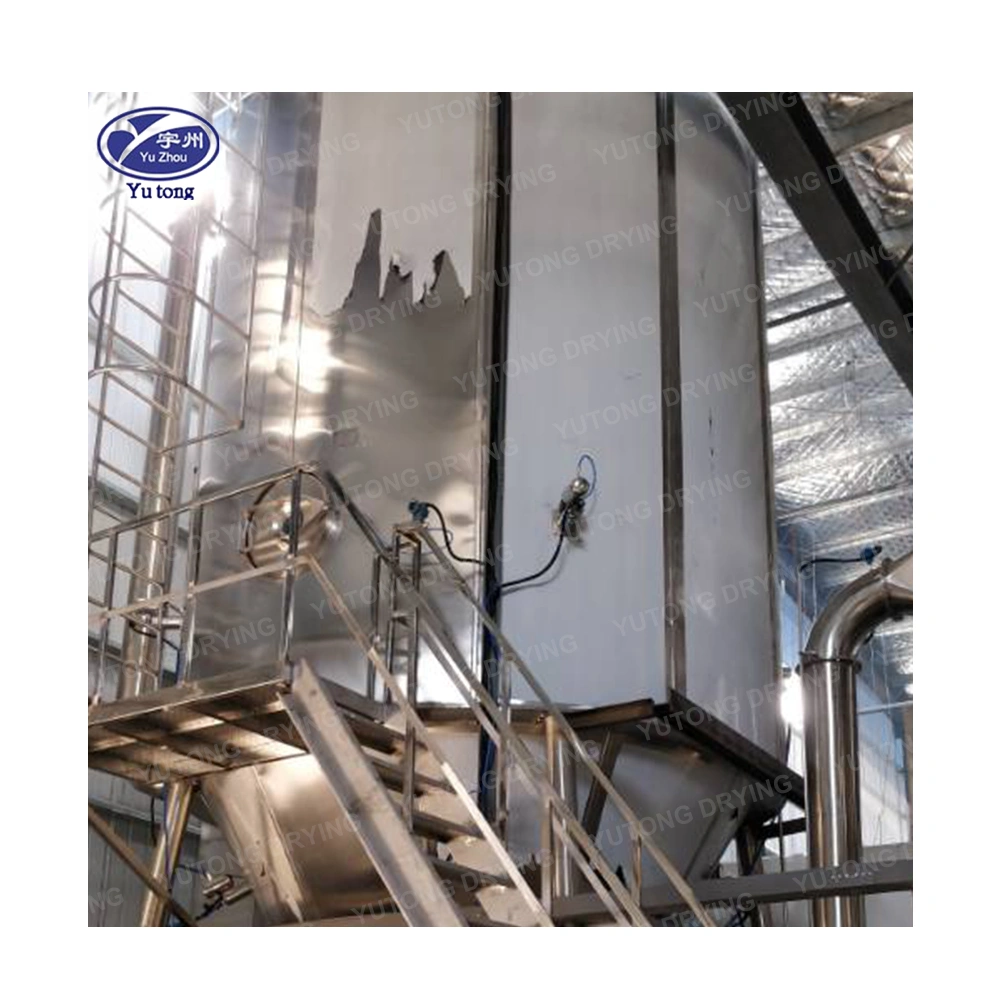

Product Detail

In the ever-evolving landscape of food processing, the porridge spray dryer dehydrator stands out as a transformative innovation. This cutting-edge technology is redefining how porridge and other liquid-based food products are preserved, enhancing both their quality and longevity. For those immersed in the food production industry or anyone with a curiosity for pioneering food technologies, understanding this equipment is not just beneficial but essential. This article will explore the intricacies of a porridge spray dryer dehydrator, its numerous benefits, and its diverse applications, with a particular focus on regions like South Africa.

Understanding Spray Drying

Spray drying is a sophisticated process that transforms liquid food products into stable, dry powders. It offers numerous advantages in terms of storage, distribution, and consumption. Let’s delve deeper into how spray drying functions and its significance in modern food processing.

What is a Spray Dryer?

A spray dryer is an essential piece of equipment in food processing that converts liquids into dry powders. This is achieved by spraying the liquid into a heated drying chamber, where moisture is quickly evaporated. The resulting fine particles of dry product retain much of the original product’s nutritional content, ensuring a high-quality end product.

The technology behind spray drying is particularly advantageous for food products that require extended shelf life and ease of transportation. By removing the moisture content, spray dryers prevent microbial growth, thereby significantly extending the shelf life of the product. This is crucial for both small-scale producers and large food manufacturers aiming to minimize waste and maximize efficiency.

How Does a Spray Dryer Work?

Spray drying involves a meticulous process consisting of three key stages, each crucial for achieving the desired quality of the end product:

- Atomization: The process begins with atomization, where the liquid porridge is transformed into tiny droplets using a nozzle or an atomizer. This step is critical as it increases the liquid’s surface area, allowing for rapid drying.

- Drying: Once atomized, these droplets are introduced into a drying chamber filled with a stream of hot air. The intense heat causes the moisture in the droplets to evaporate almost instantaneously. This rapid drying process is essential to preserve the nutritional integrity of the product.

- Collection: The final stage involves collecting the dried particles, which have now settled at the bottom of the chamber, as a fine powder. This powder can then be packaged and stored for future use, offering a convenient and long-lasting food solution.

The efficacy of spray drying lies in its ability to produce a stable, easy-to-use powdered product that maintains the original food’s quality and nutritional value.

Advantages of Using a Porridge Spray Dryer Dehydrator

The advantages of employing a porridge spray dryer dehydrator in food processing are multifaceted, addressing both practical and economic considerations. Here, we explore the key benefits that make this technology an attractive option for food producers worldwide.

Enhanced Shelf Life and Storage

One of the most significant advantages of using a spray dryer for porridge is the dramatic increase in shelf life. By effectively removing moisture, the potential for microbial growth is virtually eliminated, allowing the product to be stored for extended periods without the risk of spoilage. This is particularly beneficial for producers looking to export their products or cater to markets with limited access to fresh ingredients.

The ability to store products for more extended periods reduces the frequency of production cycles, thereby lowering operational costs. Producers can manage inventory more efficiently, ensuring a steady supply of products without the constant pressure of immediate turnover.

Nutrient Retention

Spray drying is celebrated for its capacity to preserve the nutritional profile of the original liquid. The rapid drying process minimizes the degradation of essential nutrients, ensuring that the final powdered product retains vital vitamins and minerals. This is particularly important for nutritional supplements and health-focused food products where maintaining the integrity of nutritional content is paramount.

Consumers today are increasingly health-conscious, seeking products that offer both convenience and nutritional benefits. Spray drying meets this demand by providing a method that delivers high-quality, nutritious food products that are easy to store and use.

Cost-Effective Production

The efficiency of spray drying extends beyond its technical capabilities, offering significant economic benefits. By reducing the volume and weight of products, spray drying lowers storage and transportation costs, making it a cost-effective solution for producers. The powdered form requires less packaging material, further reducing costs and environmental impact.

Moreover, spray drying is a scalable process that accommodates various production capacities. This flexibility makes it an appealing option for both small enterprises and large-scale manufacturers, allowing them to adjust production levels according to market demand without incurring excessive costs.

Versatility

One of spray drying technology’s standout features is its versatility. It can be applied to a wide range of food products beyond porridge, including dairy products, fruit juices, and even coffee. This adaptability makes it a popular choice in the food industry, enabling producers to diversify their product offerings and meet varying consumer preferences.

The ability to produce consistent, high-quality products across different food categories enhances brand reputation and consumer trust. As a result, spray drying is not only a functional process but also a strategic tool for businesses looking to expand their market presence.

Spray Drying in South Africa

As a country with a rich agricultural heritage, South Africa presents unique opportunities and challenges in food processing. Spray drying technology is increasingly being adopted to address these needs, offering innovative solutions to enhance the country’s food production capabilities.

The Growing Demand for Spray Dryers

In South Africa, the demand for spray dryers has been steadily increasing, driven by the country’s diverse agricultural base and the quest for efficient food processing methods. The ability to transform local produce into long-lasting, high-value products is a significant advantage for South African producers looking to compete in global markets.

As the food processing industry continues to expand, spray dryers are becoming indispensable components. They enable producers to add value to raw materials and meet the growing demand for processed food products both domestically and internationally.

Local Innovations and Applications

South African companies are at the forefront of adopting spray drying technology for a variety of applications. The production of powdered milk, fruit powders, and nutritional supplements are just a few areas where spray drying has made a substantial impact. This technology allows local producers to tap into new markets, offering innovative products that cater to health-conscious consumers and those seeking convenient food solutions.

Moreover, spray drying supports the development of niche products that leverage South Africa’s unique agricultural produce. By converting local fruits and herbs into powdered forms, producers can create distinctive products that showcase the country’s rich biodiversity and culinary heritage.

Challenges and Opportunities

While the adoption of spray dryers in South Africa presents numerous opportunities, it also comes with challenges. The initial cost of equipment and the need for skilled operators are significant hurdles that must be overcome. However, with strategic investment and training, these challenges can be addressed, paving the way for enhanced food processing capabilities in the region.

Government support and industry collaboration are crucial in fostering an environment that encourages innovation and investment in spray drying technology. By addressing these challenges, South Africa can position itself as a leader in food processing, leveraging its agricultural strengths to drive economic growth and sustainability.

Choosing the Right Spray Dryer

Selecting the appropriate spray dryer is a critical decision that can impact the efficiency and success of food processing operations. Various factors must be considered to ensure the equipment meets specific production needs and enhances operational capabilities.

Factors to Consider

When choosing a spray dryer, several key factors should be evaluated to ensure it aligns with production requirements and business objectives:

- Capacity: The size of the spray dryer should match the production scale, ensuring it can handle the desired output volume without compromising quality.

- Energy Efficiency: Opt for models that offer efficient energy use to reduce operational costs and environmental impact. Energy-efficient spray dryers contribute to sustainable production practices and long-term cost savings.

- Ease of Maintenance: Regular maintenance is essential for optimal performance and longevity of the equipment. Choose a model that is easy to service and maintain, minimizing downtime and maintenance costs.

- Technology Integration: Advanced features, such as automated controls and real-time monitoring, can enhance the efficiency and consistency of the drying process. These features offer greater control over product quality and streamline operations.

Leading Brands and Suppliers

South Africa boasts several reputable brands and suppliers offering high-quality spray dryers. Conducting thorough research and consulting with industry experts can help businesses identify the best equipment to meet their specific needs and budget. Partnering with reliable suppliers ensures access to technical support, training, and after-sales service, all of which are crucial for successful implementation and operation.

Conclusion

The porridge spray dryer dehydrator is a vital tool in modern food processing, offering unparalleled benefits in terms of shelf life extension, nutrient retention, and cost reduction. As the demand for efficient food processing solutions continues to grow in South Africa, spray dryers are poised to play an increasingly important role in the industry.

By understanding the benefits and applications of spray drying, businesses can make informed decisions that enhance their production capabilities and meet the evolving needs of consumers. Whether you’re a small business owner or part of a more extensive food production operation, embracing this technology could transform your approach to food preservation and production. With the right equipment and expertise, the possibilities are endless, paving the way for innovation, growth, and sustainability in the food industry.

Specifications

|

spec

|

ZPG-25

|

ZPG-50

|

ZPG-80

|

ZPG-100

|

ZPG-150

|

ZPG-200

|

ZPG-300

|

|

|

evaporation capacity(kg/h)

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

|

process amount of material liquid(kg/h)

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

|

output of finished pcoduct(kg/h)

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

24-42

|

36.8-56.4

|

55-85

|

|

|

solid content of material liquid( %)

|

18-30

|

|||||||

|

moisture content of finished product( %)

|

3-5

|

|||||||

|

electric power(kw)

|

63

|

132

|

153

|

204

|

246

|

330

|

||

|

heat source

|

Steam pius electricity

|

|||||||

|

Collecting method of product and its efficiency

|

Grade one or two or three stage cyclone wet dust remover is greater than or equal to 95%

|

|||||||

|

automatic control meters and instruments

|

indicator of not air and exhaust air temperature

|

|||||||

|

temperature of air inlet(℃)

|

160-220

|

|||||||

|

temperature of air outlet(℃)

|

80-100

|

|||||||

|

L

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15000

|

|

|

overal dimensions(mm)

|

W

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

H

|

6200

|

6900

|

8000

|

8900

|

10750

|

11900

|

13000

|

|

Applications

Applicable Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Retail, Food & Beverage Shops