Table of Contents

Product Detail

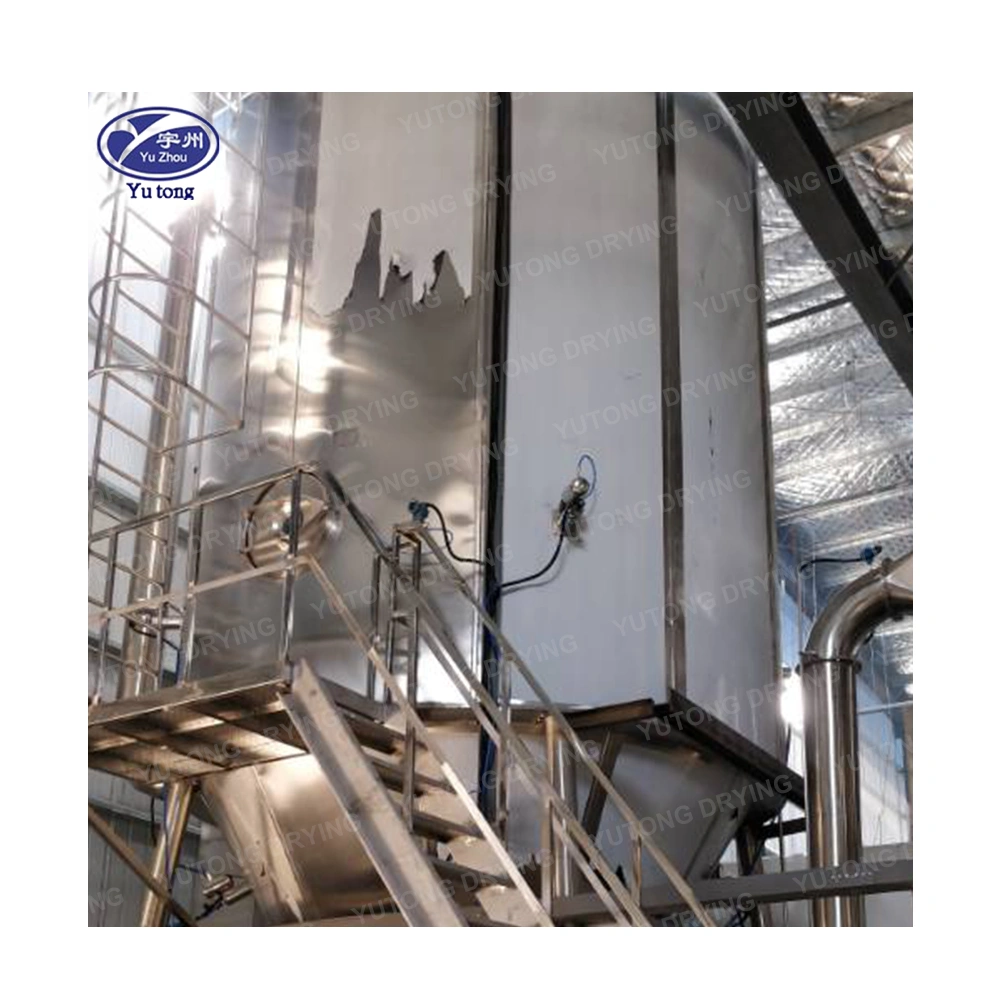

bacteria spray dryer

The production of probiotics and other beneficial bacteria is a complex process that requires precision and care. One of the most crucial pieces of equipment used in this process is the bacteria spray dryer. In this article, we will explore what a bacteria spray dryer is, how it works, and its importance in the production of probiotics and lactic acid bacteria.

What is a Bacteria Spray Dryer?

A bacteria spray dryer is a machine used to convert liquid bacteria cultures into dry powder. This drying process is essential for preserving the bacteria’s viability and making it easier to store, transport, and incorporate into various products. The spray drying technique is highly efficient, ensuring that the beneficial properties of the bacteria are retained throughout the process.

The Science Behind Spray Drying

Spray drying is a sophisticated process that involves evaporating the moisture content from a liquid solution. It is a preferred method in the biotechnology field because it allows for the precise control of environmental variables. This precision ensures that the integrity of sensitive bacteria is maintained, preventing denaturation or loss of viability. Understanding the scientific principles behind spray drying helps in optimizing the process for maximum efficiency and efficacy.

Key Components of a Bacteria Spray Dryer

A bacteria spray dryer consists of several key components, each playing a crucial role in the drying process. These components include the atomizer, drying chamber, heat source, and collection system. The atomizer breaks down the liquid into fine droplets, while the drying chamber and heat source facilitate the rapid removal of moisture. The collection system then gathers the dried particles, ensuring minimal product loss.

Importance in Probiotic Production

The role of bacteria spray dryers in probiotic production cannot be overstated. They enable manufacturers to produce stable, high-quality probiotic powders that retain their beneficial properties over time. This stability is critical for the efficacy of probiotics, as it ensures that the bacteria remain viable until they reach the consumer. The ability to convert liquid cultures into a dry form also enhances the ease of formulation and increases the shelf life of probiotic products.

How Does a Bacteria Spray Dryer Work?

The spray drying process involves several key steps:

Preparation of Bacteria Culture

The process begins with the preparation of a liquid bacteria culture. This culture contains the specific bacteria strain that needs to be dried. Preparing the culture involves carefully selecting and cultivating the bacteria under controlled conditions to ensure optimal growth. The selection process may include choosing strains with specific health benefits or those that exhibit high viability during the drying process. Cultivation is carried out in sterile environments to prevent contamination and ensure the purity of the final product.

Atomization: Creating the Perfect Mist

The liquid culture is then fed into the spray dryer, where it is atomized into tiny droplets. This is achieved using a nozzle or rotary atomizer, which creates a fine mist of the liquid. Atomization is a critical step as it influences the drying rate and the quality of the final powder. The atomizer must be calibrated to produce droplets of uniform size, which ensures consistent drying and minimizes variations in the powder’s properties. Different atomization techniques may be chosen based on the specific requirements of the bacteria being processed.

Drying Chamber: The Heart of the Process

The atomized droplets are introduced into a drying chamber, where they come into contact with hot air. The hot air rapidly evaporates the moisture from the droplets, leaving behind dry particles. The temperature and airflow within the drying chamber must be precisely controlled to ensure efficient moisture removal without damaging the bacteria. The design of the drying chamber, including its size and shape, can significantly affect the drying process’s efficiency and the quality of the final product.

Collection of Powder: Harvesting the Product

The dry particles are collected at the bottom of the drying chamber, where they are separated from the air stream using a cyclone separator or bag filter. This step involves carefully collecting the powder to prevent loss and contamination. The separation method chosen can affect the purity and yield of the final product. Cyclone separators and bag filters are commonly used due to their efficiency in capturing fine particles and their ability to maintain product integrity.

Packaging: Ensuring Quality and Longevity

Finally, the dry bacteria powder is collected and packaged for storage or transportation. Packaging plays a crucial role in maintaining the powder’s quality and ensuring its longevity. The packaging material must protect the powder from moisture, light, and oxygen, which can degrade the bacteria. Proper packaging ensures that the product remains viable and effective until it reaches the end-user. Manufacturers often use airtight, opaque containers to maximize shelf life and maintain the powder’s potency.

Advantages of Using a Bacteria Spray Dryer

Using a bacteria spray dryer offers several advantages:

Efficiency: Streamlining the Drying Process

Spray drying is a fast and efficient method of converting liquid cultures into dry powder, reducing processing time and costs. The speed of the spray drying process allows manufacturers to produce large quantities of bacteria powder quickly, meeting the market’s demands. This efficiency also translates to cost savings, as less time and energy are required compared to traditional drying methods. The streamlined process minimizes production bottlenecks, enhancing overall operational efficiency.

Preservation: Retaining Viability and Potency

The rapid drying process helps preserve the bacteria’s viability, ensuring that the final product retains its beneficial properties. Preservation of viability is crucial for probiotics, as the health benefits are directly linked to the live bacteria reaching the consumer. The gentle yet effective drying conditions in a spray dryer help maintain the bacteria’s structure and metabolic activity. This preservation ensures that the probiotics remain potent and practical throughout their shelf life.

Uniformity: Consistency in Every Batch

Spray drying produces a uniform powder with consistent particle size, making it easier to mix and incorporate into various formulations. Uniformity is essential for ensuring that each dose of a probiotic product contains the correct number of viable bacteria. Consistent particle size also facilitates better dissolution and absorption in the body. The uniformity achieved through spray drying enhances the reliability and efficacy of probiotic products, contributing to consumer satisfaction and trust.

Applications of Bacteria Spray Dryers

Bacteria spray dryers are used in various industries, particularly in the production of probiotics and lactic acid bacteria.

Probiotic Spray Dryer: A Delicate Balance

Probiotics are live microorganisms that provide health benefits when consumed in adequate amounts. They are commonly used in dietary supplements, food products, and pharmaceuticals. A probiotic spray dryer is specifically designed to handle the delicate nature of probiotic cultures, ensuring that the drying process does not harm the bacteria’s viability.

Dietary Supplements: Enhancing Health with Ease

Probiotic powders are often used in dietary supplements, providing consumers with an easy way to incorporate beneficial bacteria into their diets. These supplements are available in various forms, such as capsules, tablets, and sachets, catering to consumer preferences. The convenience and health benefits of probiotic supplements make them a popular choice among health-conscious individuals. Spray drying ensures that these supplements contain high-quality, viable bacteria, enhancing their effectiveness.

Food Products: Enriching Nutrition Naturally

Many food products, such as yogurts and fermented beverages, contain probiotics to enhance their nutritional value. Probiotics are a natural way to boost gut health and support overall well-being. Spray-dried probiotic powders are easily incorporated into different food matrices, maintaining their viability during processing and storage. This versatility allows manufacturers to innovate and develop functional foods that cater to the growing demand for health-promoting products.

Pharmaceuticals: Targeting Health with Precision

Probiotics are also used in pharmaceutical formulations, offering potential health benefits in the prevention and treatment of various conditions. The pharmaceutical industry utilizes probiotics for their ability to modulate the gut microbiota and enhance immune function. Spray drying ensures that pharmaceutical-grade probiotics maintain their potency and stability, meeting the stringent quality standards required in drug formulations. This precision in formulation ensures that probiotics deliver targeted health benefits effectively.

Lactic Acid Spray Dryer: Supporting Fermentation

Lactic acid bacteria are another critical group of microorganisms used in food and pharmaceutical industries. A lactic acid spray dryer is used to dry cultures of these bacteria, which are essential for the production of fermented foods and beverages.

Fermented Foods: Crafting Flavorful Traditions

Lactic acid bacteria play a crucial role in the production of fermented foods, such as sauerkraut, kimchi, and pickles, by converting sugars into lactic acid. This fermentation process not only enhances the flavor and texture of foods but also extends their shelf life. Spray drying enables the production of stable lactic acid bacteria cultures that can be easily used in various fermentation processes. This stability ensures that traditional flavors are consistently achieved, preserving culinary heritage.

Dairy Products: Perfecting Taste and Texture

These bacteria are also used in the production of dairy products like cheese and yogurt, where they contribute to flavor and texture. The role of lactic acid bacteria in dairy production is vital, as they aid in the development of desired sensory attributes. Spray-dried cultures provide a reliable source of bacteria for dairy manufacturers, ensuring consistent quality and taste. The ability to control fermentation with precision enhances the appeal of dairy products to consumers.

Probiotics: Blending Health with Tradition

Lactic acid bacteria are often included in probiotic formulations due to their health benefits. These bacteria are known for their ability to improve gut health and support immune function. Spray drying preserves the viability of lactic acid bacteria, allowing them to be effectively incorporated into probiotic products. The combination of traditional fermentation benefits with modern health advantages makes lactic acid bacteria a valuable component in the probiotic industry.

Factors to Consider When Choosing a Bacteria Spray Dryer

When selecting a bacteria spray dryer for your production needs, several factors should be considered:

Capacity: Meeting Production Demands

The spray dryer’s capacity should align with your production requirements. Consider the volume of liquid culture you need to process and choose a machine that can handle this capacity efficiently. A dryer with insufficient capacity may lead to production delays and increased costs, while an oversized dryer may result in unnecessary energy consumption. Evaluating your production needs and selecting the right capacity ensures optimal performance and cost-effectiveness.

Temperature Control: Preserving Bacterial Integrity

Temperature control is crucial in the spray drying process, as excessive heat can damage the bacteria. Look for a spray dryer that offers precise temperature control to ensure the bacteria’s viability is maintained. Advanced temperature control systems allow for adjustments to accommodate different bacteria strains and their specific temperature sensitivities. Maintaining the correct temperature balance is essential for producing high-quality, viable bacteria powders.

Atomization Method: Choosing the Right Technique

Different spray dryers use various atomization methods, such as rotary atomizers or nozzle atomizers. Each method has its advantages and disadvantages, so consider which method best suits your needs. Rotary atomizers are known for their ability to handle high-viscosity liquids, while nozzle atomizers provide more precise droplet size control. Understanding the characteristics of each method helps in selecting the most suitable option for your specific application.

Cleaning and Maintenance: Ensuring Longevity

Another important consideration is ease of cleaning and maintenance. Choose a spray dryer with a design that allows for easy cleaning and minimal maintenance to reduce downtime and ensure consistent performance. Regular maintenance is crucial for preventing contamination and ensuring the longevity of the equipment. A user-friendly design that facilitates quick cleaning and maintenance can significantly enhance operational efficiency and reduce overall costs.

Conclusion

In conclusion, a bacteria spray dryer is an essential tool in the production of probiotics and lactic acid bacteria. Its ability to efficiently convert liquid cultures into dry powder form while preserving the bacteria’s viability makes it invaluable in various industries. By understanding the process and benefits of bacteria spray drying, you can make informed decisions when choosing the right equipment for your production needs.

Whether you’re producing probiotics for dietary supplements, food products, or pharmaceuticals, a bacteria spray dryer offers the efficiency and reliability needed to ensure the success of your production process. Investing in the right spray drying technology not only enhances product quality but also contributes to the growth and innovation of the probiotic industry.

Specifications

|

spec

|

ZPG-25

|

ZPG-50

|

ZPG-80

|

ZPG-100

|

ZPG-150

|

ZPG-200

|

ZPG-300

|

|

|

evaporation capacity(kg/h)

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

|

process amount of material liquid(kg/h)

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

|

output of finished pcoduct(kg/h)

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

24-42

|

36.8-56.4

|

55-85

|

|

|

solid content of material liquid( %)

|

18-30

|

|||||||

|

moisture content of finished product( %)

|

3-5

|

|||||||

|

electric power(kw)

|

63

|

132

|

153

|

204

|

246

|

330

|

||

|

heat source

|

Steam pius electricity

|

|||||||

|

Collecting method of product and its efficiency

|

Grade one or two or three stage cyclone wet dust remover is greater than or equal to 95%

|

|||||||

|

automatic control meters and instruments

|

indicator of not air and exhaust air temperature

|

|||||||

|

temperature of air inlet(℃)

|

160-220

|

|||||||

|

temperature of air outlet(℃)

|

80-100

|

|||||||

|

L

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15000

|

|

|

overal dimensions(mm)

|

W

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

H

|

6200

|

6900

|

8000

|

8900

|

10750

|

11900

|

13000

|

|

Applications

Applicable Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Retail, Food & Beverage Shops