The vacuum drying machine is a specialized piece of equipment that plays a crucial role in various industries by removing moisture from materials under reduced pressure conditions. This process offers several advantages over traditional drying methods and is widely used for a diverse range of applications.

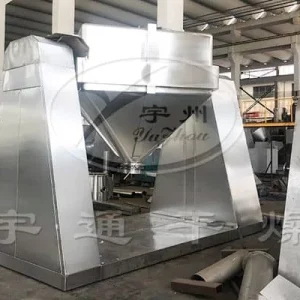

At its core, a vacuum drying machine consists of a sealed chamber where the drying process takes place. The chamber is connected to a vacuum pump, which is responsible for creating and maintaining the low-pressure environment. The machine may also include a heating system to accelerate the drying process by providing the necessary energy to evaporate the moisture.

The operation of a vacuum drying machine begins by placing the material to be dried inside the chamber. The chamber is then sealed and the vacuum pump is activated. As the pressure inside the chamber is reduced, the boiling point of water and other volatile substances in the material is lowered. This allows the moisture to evaporate more easily at lower temperatures compared to drying in atmospheric pressure.

The heating system in the vacuum drying machine can be of various types, such as electric heaters, steam coils, or hot oil circulation. The choice of heating method depends on the specific requirements of the material being dried and the process conditions. The heating system provides the necessary heat to the material, increasing the kinetic energy of the moisture molecules and facilitating their evaporation.

One of the key advantages of vacuum drying is the preservation of product quality. Since the drying occurs at lower temperatures, there is less risk of heat damage to heat-sensitive materials. This is particularly important in industries such as pharmaceuticals, food, and electronics, where the quality and integrity of the product must be maintained. For example, in the pharmaceutical industry, vacuum drying is often used to dry delicate active ingredients and biological products without compromising their activity and stability.

Another benefit of vacuum drying is the enhanced drying efficiency. The reduced pressure environment allows for more rapid removal of moisture, resulting in shorter drying times and increased productivity. Additionally, the low-pressure conditions help to remove moisture more thoroughly, leading to a lower final moisture content in the dried product. This is crucial for many applications where moisture can cause spoilage, degradation, or reduced performance.

Vacuum drying machines are also highly versatile and can handle a wide variety of materials. From solids and powders to liquids and slurries, these machines can be customized to meet the specific drying requirements of different materials. The design of the machine can be adjusted to accommodate different batch sizes, from small laboratory-scale operations to large industrial production runs.

In the food industry, vacuum drying is used to preserve the nutritional value, flavor, and color of perishable foods. Fruits, vegetables, and herbs can be vacuum-dried to extend their shelf life and make them available for consumption throughout the year. Vacuum-dried foods also have a lighter weight and smaller volume, making them easier to store and transport.

In the electronics industry, vacuum drying is essential for removing moisture from sensitive components such as printed circuit boards and semiconductor devices. Moisture can cause corrosion and electrical failures, so it is crucial to ensure that these components are completely dry before use. Vacuum drying provides a reliable and efficient method for achieving the required low moisture levels.

For the pharmaceutical industry, vacuum drying is a critical step in the production of drugs and vaccines. The low-temperature drying process helps to maintain the activity and stability of active ingredients, ensuring the efficacy and safety of the final product. Vacuum drying also allows for the removal of residual solvents, which is important for meeting regulatory requirements.

In conclusion, the vacuum drying machine is a valuable tool in many industries, offering a combination of quality preservation, efficiency, and versatility. By removing moisture under reduced pressure conditions, these machines enable the production of high-quality products with extended shelf life and improved performance. As technology continues to advance, vacuum drying machines are likely to become even more sophisticated and efficient, further expanding their applications in various fields.